Heavy-caliber high-temperature pilot-operated type control valve

A pilot-operated, large-diameter technology, applied in the direction of lift valves, safety valves, balance valves, etc., can solve the problem of low safety release devices for re-closed types, and achieve the effect of improved cost performance, low cost, and perfect manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

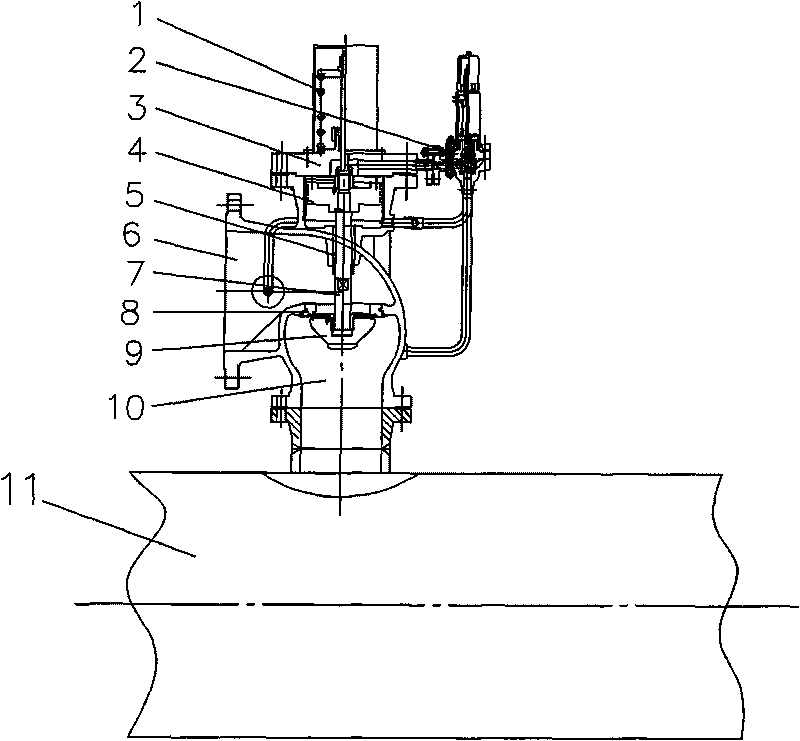

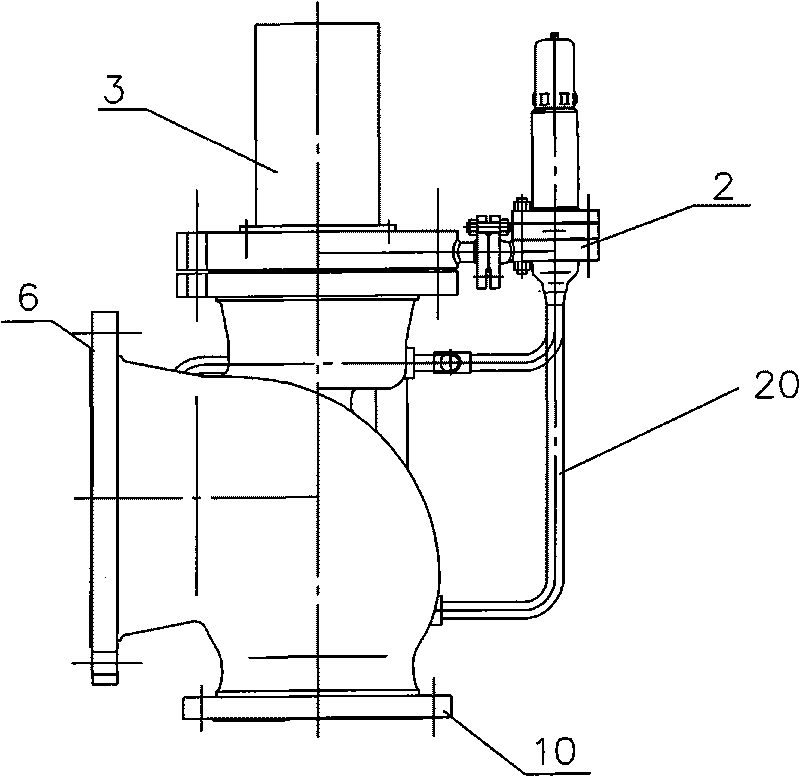

[0021] Example 1, such as Figure 1-4 As shown, this large-diameter high-temperature pilot control valve mainly includes the main control valve 3, the auxiliary pilot valve 2 and the pressure-bearing equipment 11, the main control valve 3 is connected with the auxiliary pilot valve 2, and the auxiliary pilot valve 2 passes through the bypass pipe The passage 12 communicates with the outlet port 6 of the main control valve 3, the bypass pipe 12 is provided with a check valve 13, the bottom of the main control valve 3 is provided with a nozzle 15, the nozzle 15 forms an inlet chamber 10, and the inlet chamber 10 is connected to the pressure-bearing The device 11 is connected and fixed. The main control valve 3 mainly includes a valve seat 8, a valve stem 7, a valve disc 9, a movable component and a guide sleeve 5, the valve seat 8 is provided with a valve stem 7, and the lower end of the valve stem 7 is provided with a valve disc 9, and the valve disc 9 is located at the lower ...

Embodiment 2

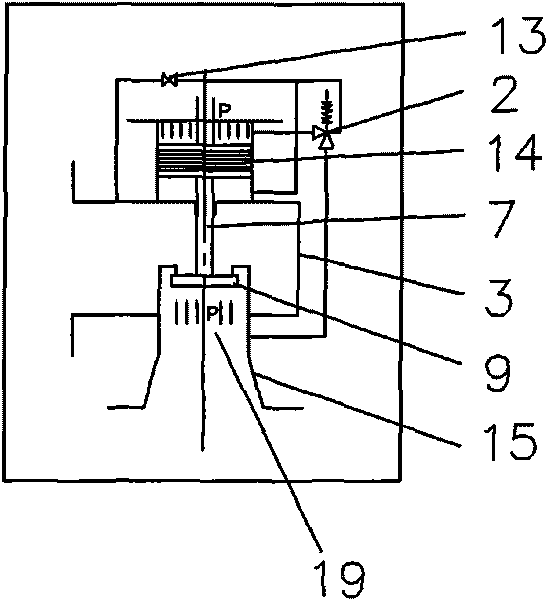

[0022] Example 2, such as Figure 5-8 As shown, the main structure is the same as that of Embodiment 1, the outlet chamber 6 of the main control valve 3 is connected to the evaporator 16 , and the secondary pilot valve 2 communicates with the evaporator 16 through the main pipeline 20 . The structure at this time forms a pressure-temperature control valve. The bearing pressure 19 of the inlet chamber 10, the discharge signal 18 of the outlet chamber 6, and the control signal 17 generated by the evaporator 16 are all transmitted to the auxiliary pilot valve 2, thereby affecting the operation of the main control valve 3. operate. The difference between the inlet pressure of the main valve and the control pressure of the pilot valve is not more than 2.5 MPa, and the opening of the valve is realized by using the area difference between the piston chamber of the main valve and the disc 9 of the main valve.

[0023] The present invention utilizes the medium pressure in the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com