Four-way valve for absorption drying tower

An adsorption drying and four-way valve technology, applied in the field of four-way valves, can solve problems such as complicated connection of intake pipes, inconvenient installation and maintenance, and complicated connection of parts, and achieve the effect of small size, reliable performance and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

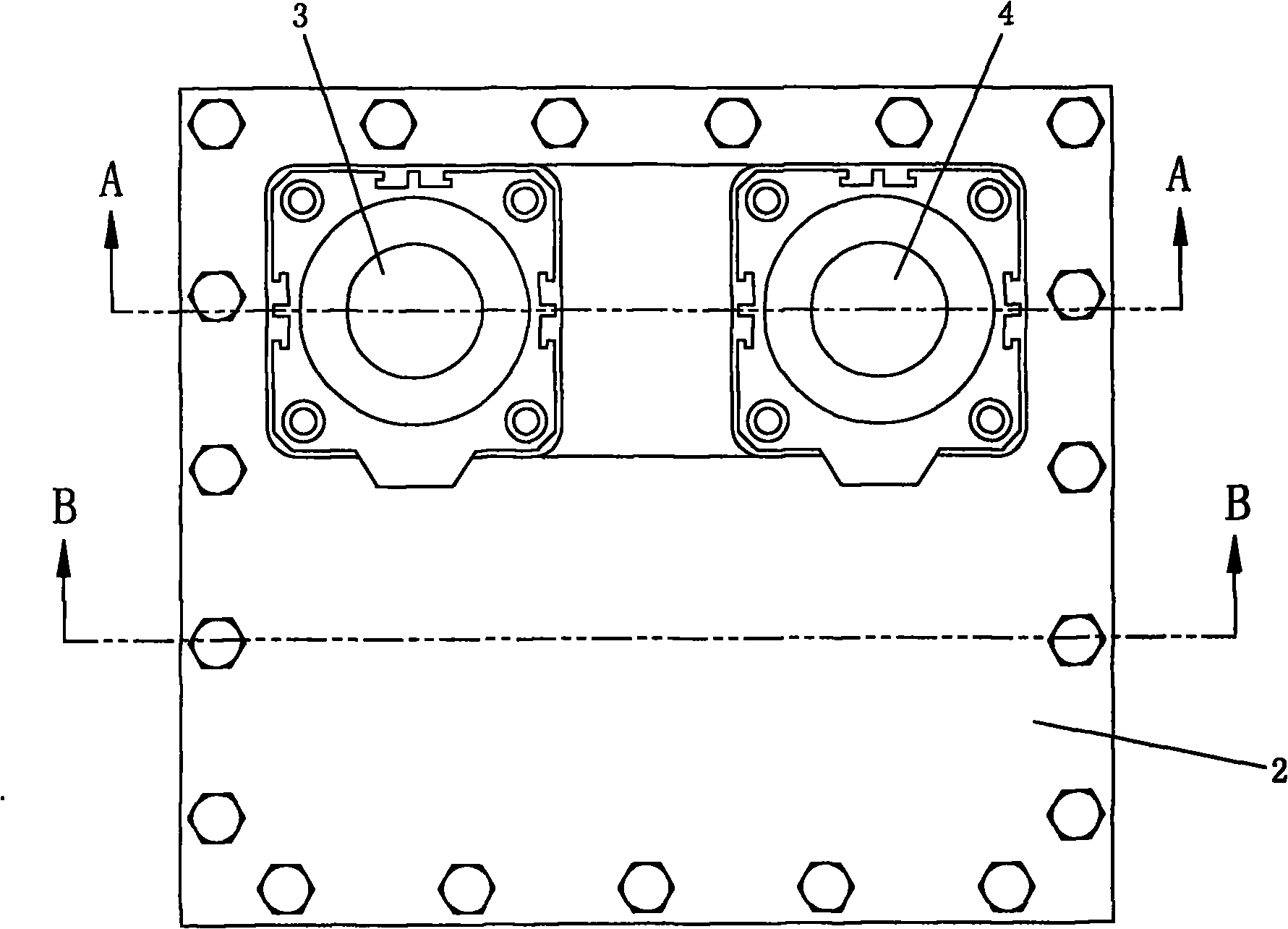

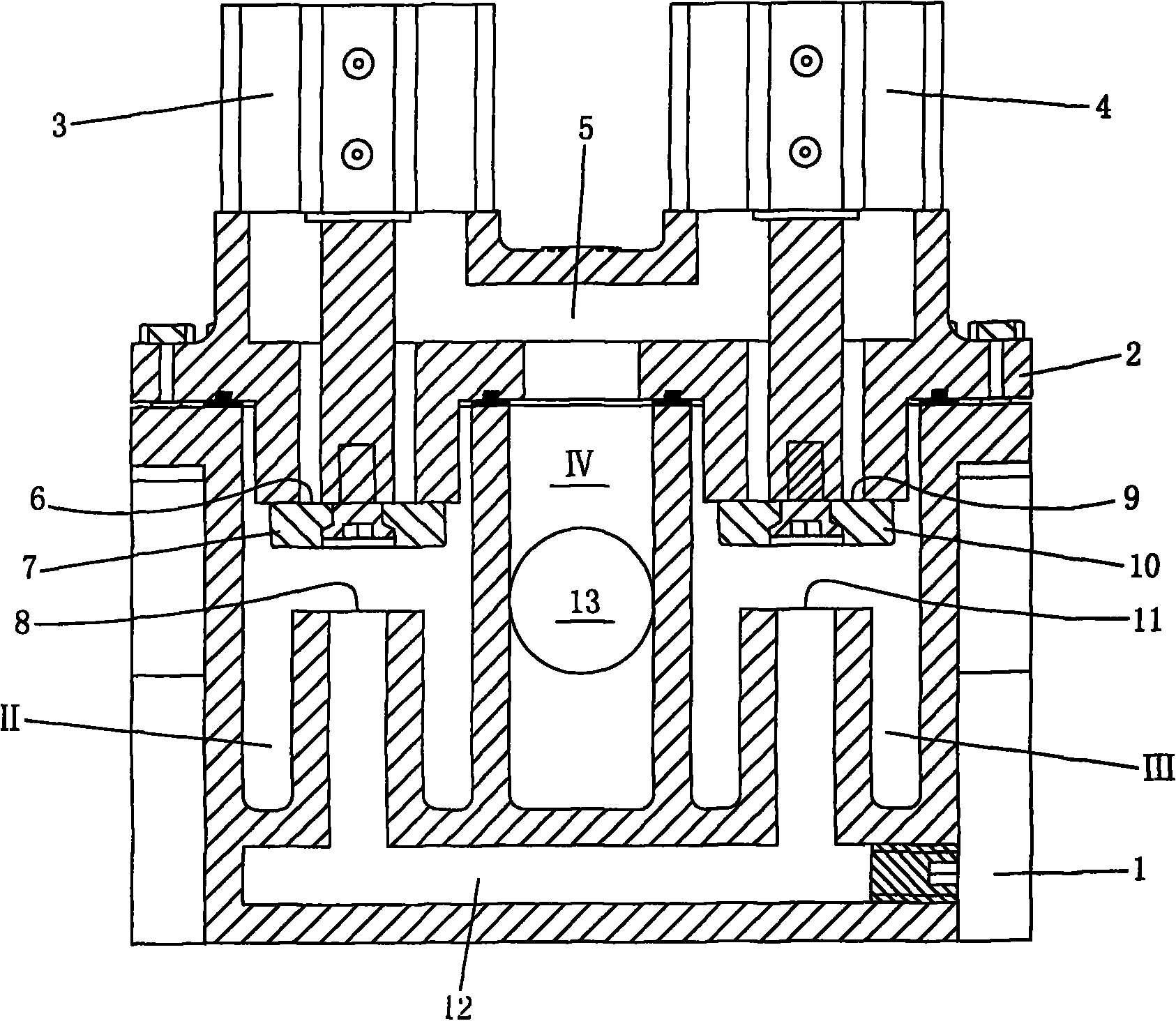

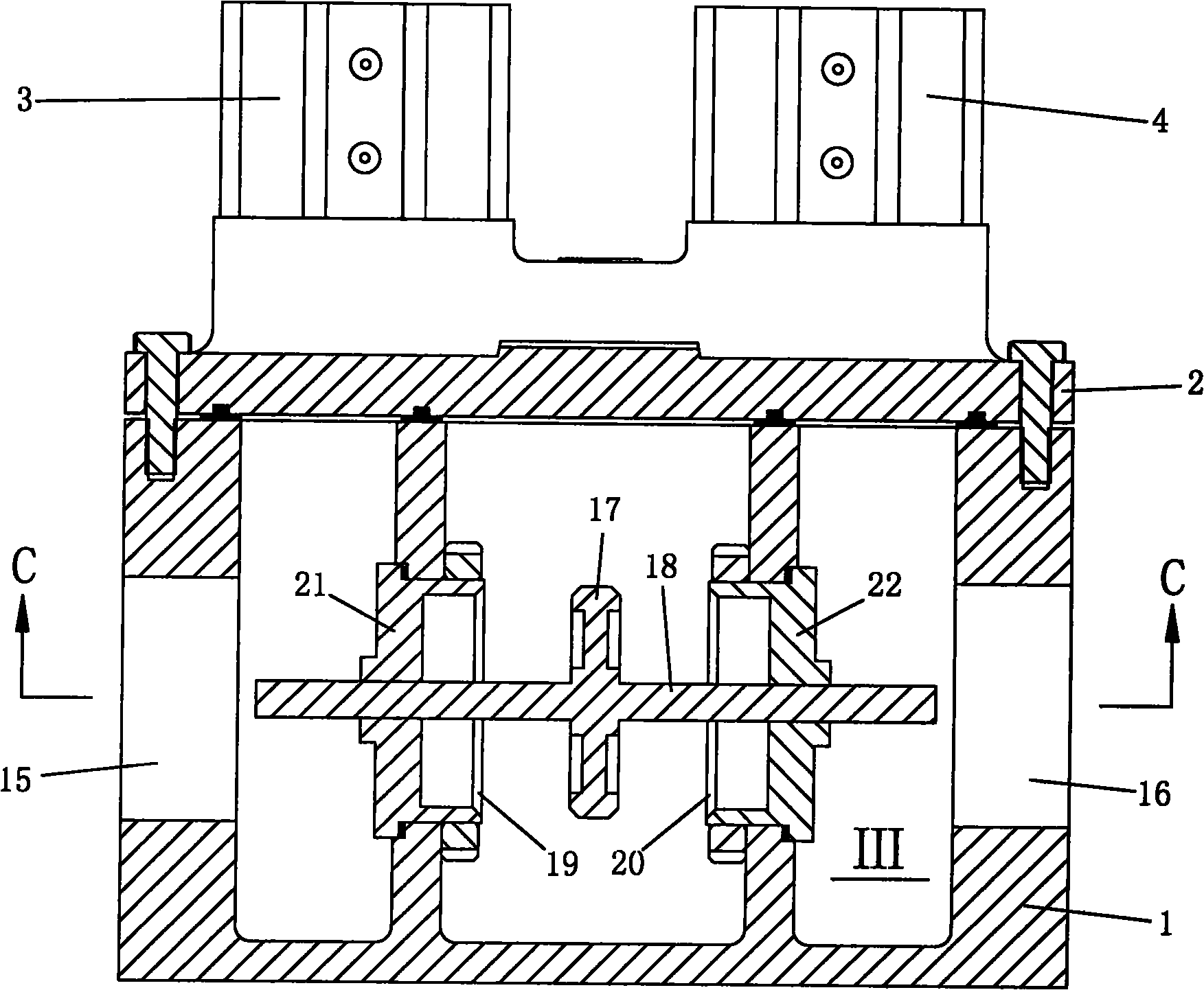

[0013] Example: see Figure 1-4 , valve body 1 of the present invention is provided with valve cover 2, and valve cover 2 is provided with left cylinder 3 and right cylinder 4, and valve body 1 is provided with intake chamber I, left tower intake and exhaust chamber II, right cylinder The tower inlet and exhaust chamber III and the exhaust gas chamber IV are correspondingly provided with an air inlet 14, a left tower connection port 15, a right tower connection port 16 and an exhaust gas outlet 13 on the wall of the valve body 1, and the air inlet chamber A left valve port 19 is provided between I and the intake and exhaust chamber II of the left tower, a right valve port 20 is provided between the intake chamber I and the intake and exhaust chamber III of the right tower, and a valve port 20 is provided in the intake chamber I. Sliding spool, the sliding spool is composed of valve disc 17 and valve stem 18 vulcanized together, the left and right sides of valve disc 17 respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com