Regulating valve

A technology for regulating valves and valve chambers, which is applied in the field of regulating valves, and can solve problems such as broken pipes of regulating valves, poor sealing performance of regulating valves, and small sealing specific pressure, and achieve the effects of enhancing sealing performance, increasing sealing specific pressure, and enhancing sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

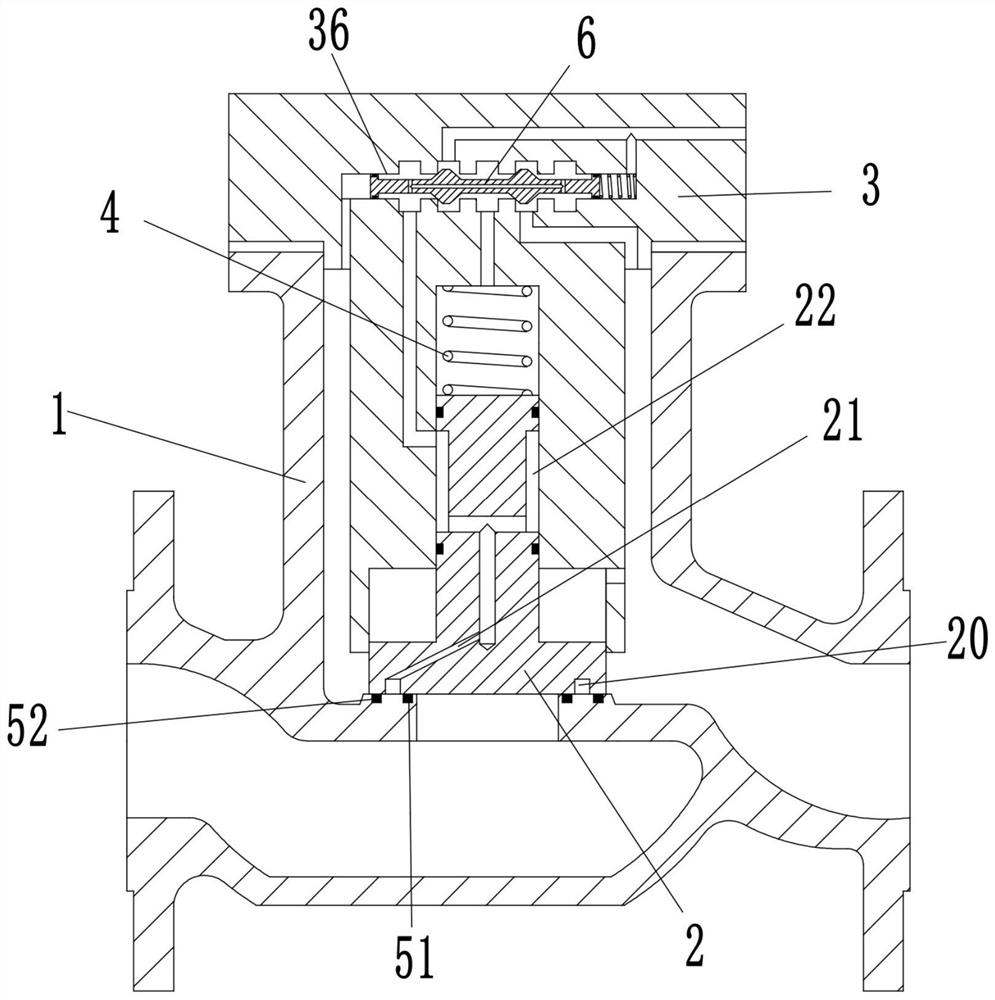

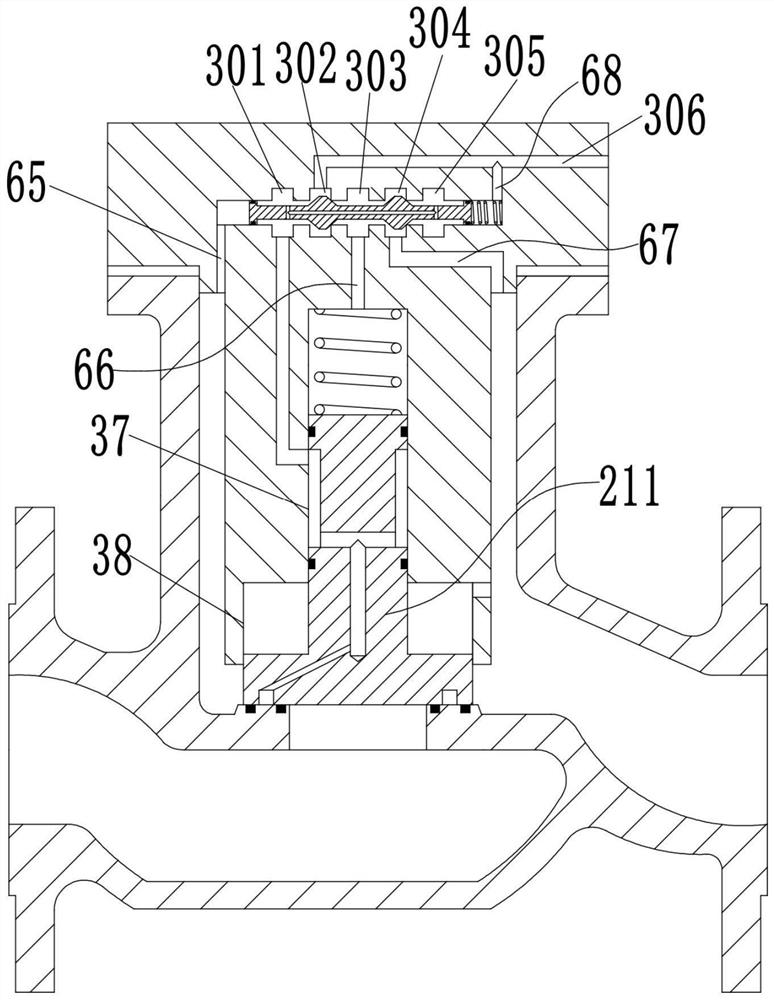

[0016] see Figure 1-3 As shown, the present invention provides a regulating valve, including a valve body 1, a valve cavity is provided in the valve body 1, a valve seat plate 1e is provided in the valve body 1, and the valve seat plate 1e separates the valve cavity It is formed into an upper valve chamber 1c and a lower valve chamber 1d, and the side of the valve body 1 is provided with an inlet pipe 1a communicating with the lower valve chamber 1d, and an outlet pipe 1b communicating with the upper valve chamber 1c; inside the valve seat plate 1e There is a valve hole 1f for communicating with the upper valve chamber 1c and the lower valve chamber 1d; the valve body 1 is fixedly installed with a valve cover 3 at the upper opening of the upper valve chamber 1c, and the outer surface of the valve cover 3 is provided with a dismounting Charge hole 306, the inner side of the valve cover 3 is provided with a boss 39 along the axial direction of the valve hole 1f, the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com