Continuous manufacturing method of steel mesh/phenol-urea-formaldehyde foam thermal insulating decoration board

A technology for thermal insulation decorative panels and manufacturing methods, applied to flat products, building structures, covering/lining, etc., can solve the problems of temperature difference between the thermal insulation layer and the decorative layer, long cycle, dry shrinkage deformation, etc., and achieve low construction and installation costs , construction and installation is convenient, the effect of short curing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Material A: parts by weight

[0062] Phenolic resin: 100

[0063] Surfactant: 5

[0064] Blowing agent (141b): 5

[0065] Material B: curing agent 10

[0066] Surface layer: 0.1mm color aluminum plate on the upper layer,

[0067] Lower layer Phenolic glued paper

[0068] Steel mesh: eye size: 20mm×20mm, steel wire diameter: 1mm.

[0069] After the two components of A and B are prepared according to the requirements in proportion, they are pumped to the high-speed mixing head of the reaction filling machine at constant temperature and in proportion, and the foaming stock solution is sprayed on the middle steel mesh and On the lower layer, enter the laminator to complete foaming and curing, and the internal temperature of the laminator is set to 55°C. It takes 8 minutes for the foaming stock solution to be delivered from the mixing head to the decorative plate.

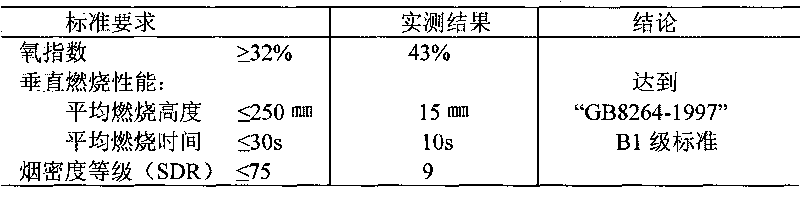

[0070] The performance of the prepared steel mesh / phenolic foam insulation decorative board:

[0071] ...

Embodiment 2

[0078] Material A: parts by weight

[0079] Phenolic-urea-formaldehyde resin: 100

[0080] Surfactant: 5

[0081] Blowing agent (141b): 5

[0082] Material B: curing agent: 10

[0083] Others are the same as Example 1, carried out according to the process of Example 1, and the properties of the prepared steel mesh / phenolic-urea-formaldehyde resin foam insulation decorative board are as follows.

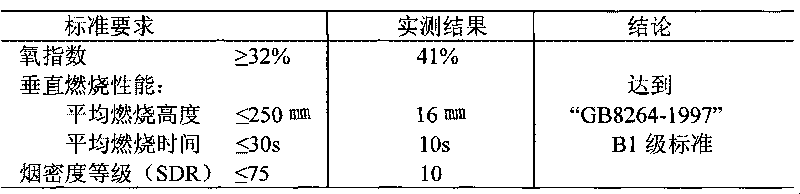

[0084] (1) Combustion performance

[0085]

[0086] (2) Wind pressure test negative pressure 4500Pa, no cracks; positive pressure 5000Pa, no cracks;

[0087] (3) Density 64.5kg / m 3 , Compressive strength 157KPa.

[0088] (4) During the production process, the entire production line has no obvious formaldehyde smell, which is caused by the reaction between the urea added in the phenolic-urea-formaldehyde resin and the formaldehyde released during the curing process.

[0089] Compared with Example 1, the oxygen index is slightly lower, but it reaches the "GB8264-1997" B1 stand...

Embodiment 3

[0091] According to example 2 formula, only in A material, increase 3% filler, foaming process is the same as example 1. The density of the decorative board is 67kg / m 3 , the oxygen index reaches 43%, the compressive strength is improved to 180KPa, other properties are basically unchanged, the elasticity is improved to a certain extent compared with example 1 and example 2, and the production workshop is tasteless.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com