Preparation method of nano micellar solution of polymer with simulated cellulosa membrane structure

A nano-micelle solution and imitation cell outer membrane technology, which is applied in the field of biomimetic polymer micelles preparation, can solve the complex and cumbersome synthesis and purification process of block copolymers, affect the biocompatibility of materials and other problems, and achieve structural Compact, easy to popularize and apply, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

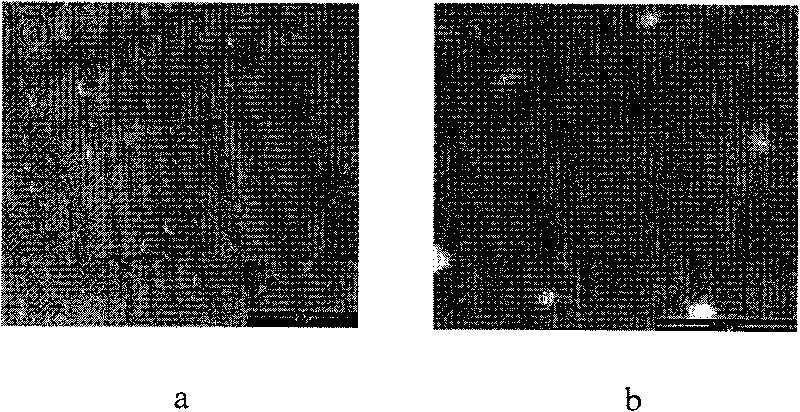

[0037] Accurately weigh 10 mg of PML70 (MPC:LMA, mol%:mol%, 7:3), and dilute to 10 ml with twice distilled water. Sonicate for 1 min, shake to dissolve the polymer completely, then shake at 60r / min for 6h. After being stirred at 50° C. for 90 minutes, a nano-micelle solution with a compact structure and a narrow particle size distribution is obtained, and the diameter of the micelles is 200-400 nanometers as determined by a scanning electron microscope.

[0038] The comparative example shows that the nano micelles without stirring and heat treatment at 50°C have a loose structure and a wide particle size distribution, with particle diameters ranging from 50 to 800 nanometers.

Embodiment 2

[0040] Weigh 10 mg of PMS30 (MPC: SMA, mol%: mol%, 3: 7), add 100 microliters of THF dropwise thereto to dissolve the polymer, add double-distilled water dropwise to it under stirring to settle to 10 ml, The THF in the solution was volatilized by stirring openly. After 2 hours, stir at 80°C for 10 minutes, cool to room temperature and centrifuge at 7980r / min for 10 minutes to remove the precipitate to obtain an aqueous solution of PMS30 polymer micelles with a concentration of 0.53mg / ml. The diameter of micellar particles was determined by scanning electron microscope to be 100-200 nanometers.

[0041] The comparative examples show that the nano-micelles without heat treatment at 80°C have a loose structure and a wide particle size distribution, with particle diameters ranging from 30 to 500 nanometers.

Embodiment 3

[0043] Taking the polymer PML30 (MPC:LMA=3:7) as an example, the process of measuring the critical micelle concentration and micelle structure of MPC polymer with better water solubility by pyrene fluorescent probe method is described.

[0044] (1) With anhydrous acetone as solvent, the concentration of pyrene prepared is 1.37×10 -4 mol / L acetone solution, ultrasonic treatment for 10min;

[0045] (2) Accurately weigh 10mg of PML30 in a 10ml volumetric flask, dissolve it with double distilled water to a constant volume, treat it with ultrasonic wave for 3min, and then shake it with an oscillator at 60r / min for 12h. Promptly obtain the PML30 polymer micelle solution that concentration is 1.0mg / ml;

[0046] (3) Use a micro-sampler to add 10 microliters of 1.37×10 to several 10ml brown volumetric flasks respectively. -4 mol / l pyrene solution in acetone, placed in a fume hood in the dark and exposed for 10 minutes to allow the acetone to volatilize naturally;

[0047] (4) Concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com