Method and equipment for preparing hydrocarbon by methyl alcohol or/ and dimethyl ether

A technology for producing hydrocarbons and dimethyl ether from dimethyl ether, which is applied in the field of chemical engineering and can solve the problems of high cycle ratio, increased energy consumption, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

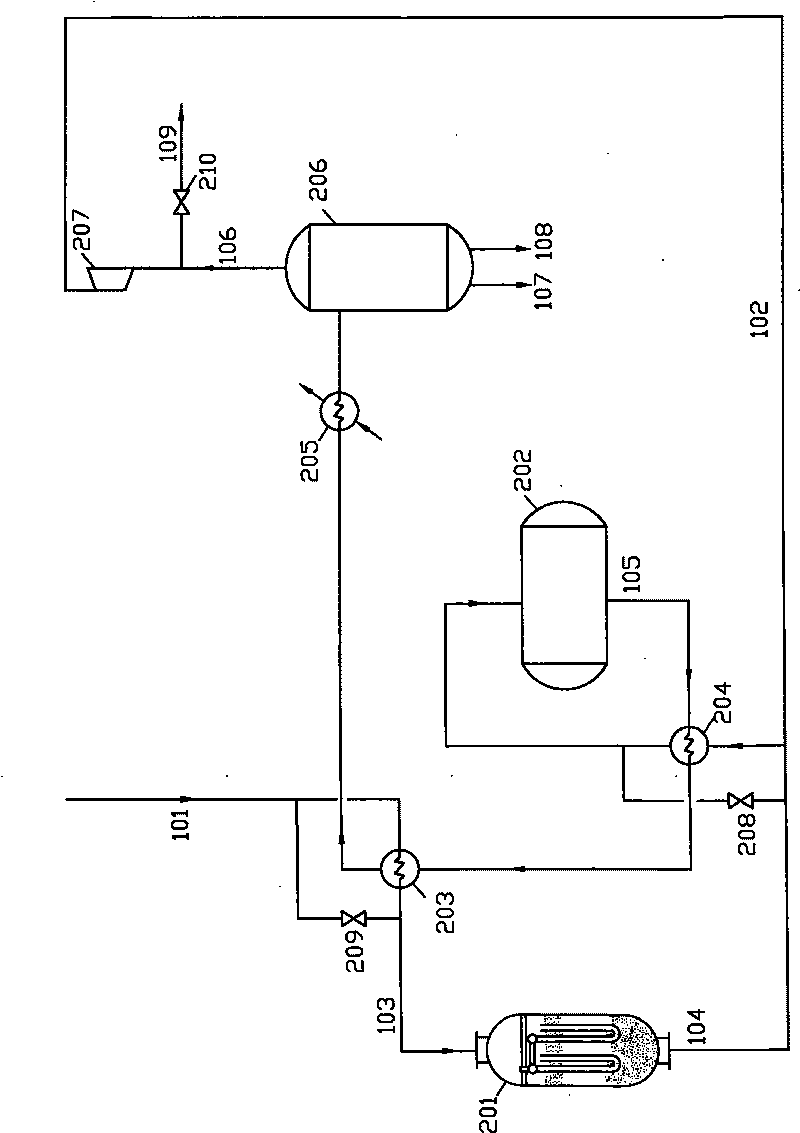

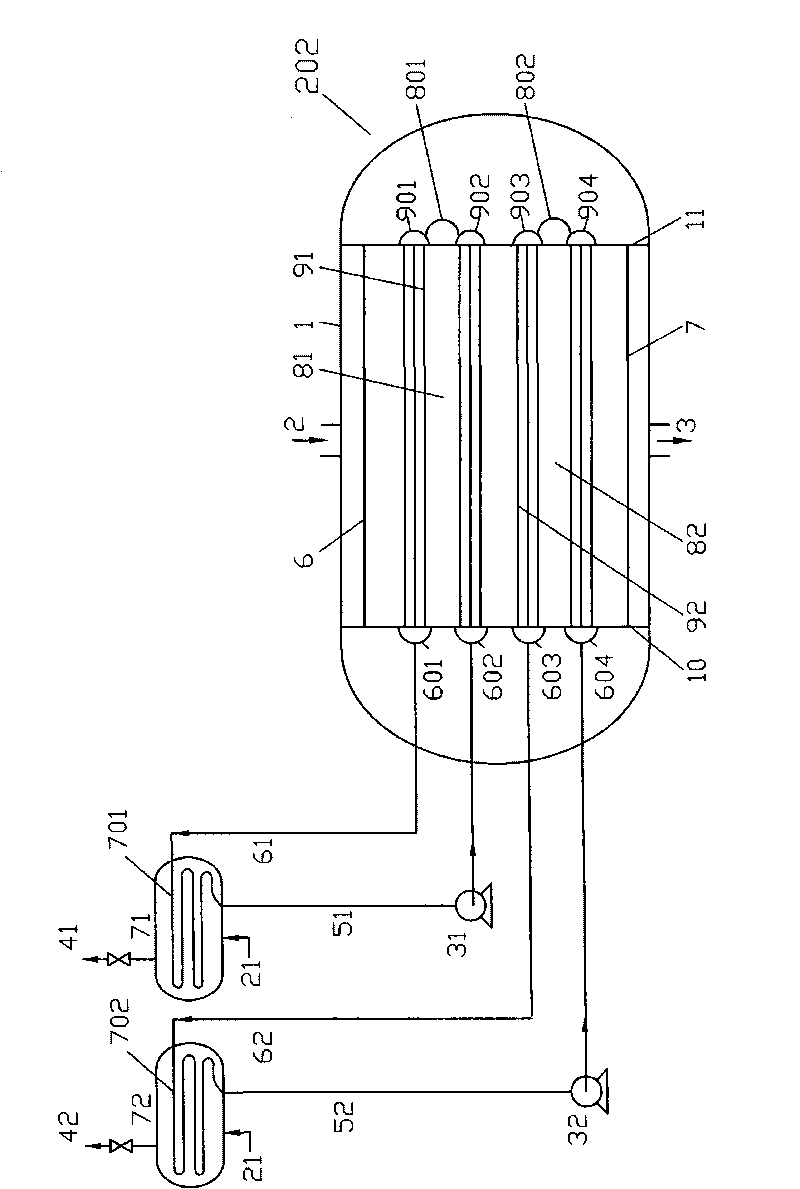

[0030] Embodiment 1: the MTG production process is as follows with methanol gasoline figure 1 , the methanol dehydration reactor 201 adopts a homogeneous dimethyl ether reactor with a diameter of 2.2 meters and a built-in gamma-alumina 30M 3 , the alkylation reactor 202 adopts such as figure 2 Horizontal heat exchange reactor, diameter 3.8 meters, catalyst layer 81, 82 filled with ZSM-5 molecular sieve catalyst 120M 3, the pressure is 2.5MPa, heated to about 130°C, the methanol gas enters the methanol dehydration reactor 201, the heat exchange tube, the absorption tube, and the catalyst layer outside the catalyst layer are heated and then exit the heat exchange tube, and are carried out on the catalyst layer at a temperature of about 300°C Methanol dehydration reaction, the gas out of the tower and the gas out of the alkylation tower exchange heat at 390°C and enter the alkylation reactor 202 for dehydration to generate hydrocarbons. Then in the catalytic reaction zone 81 a...

Embodiment 2

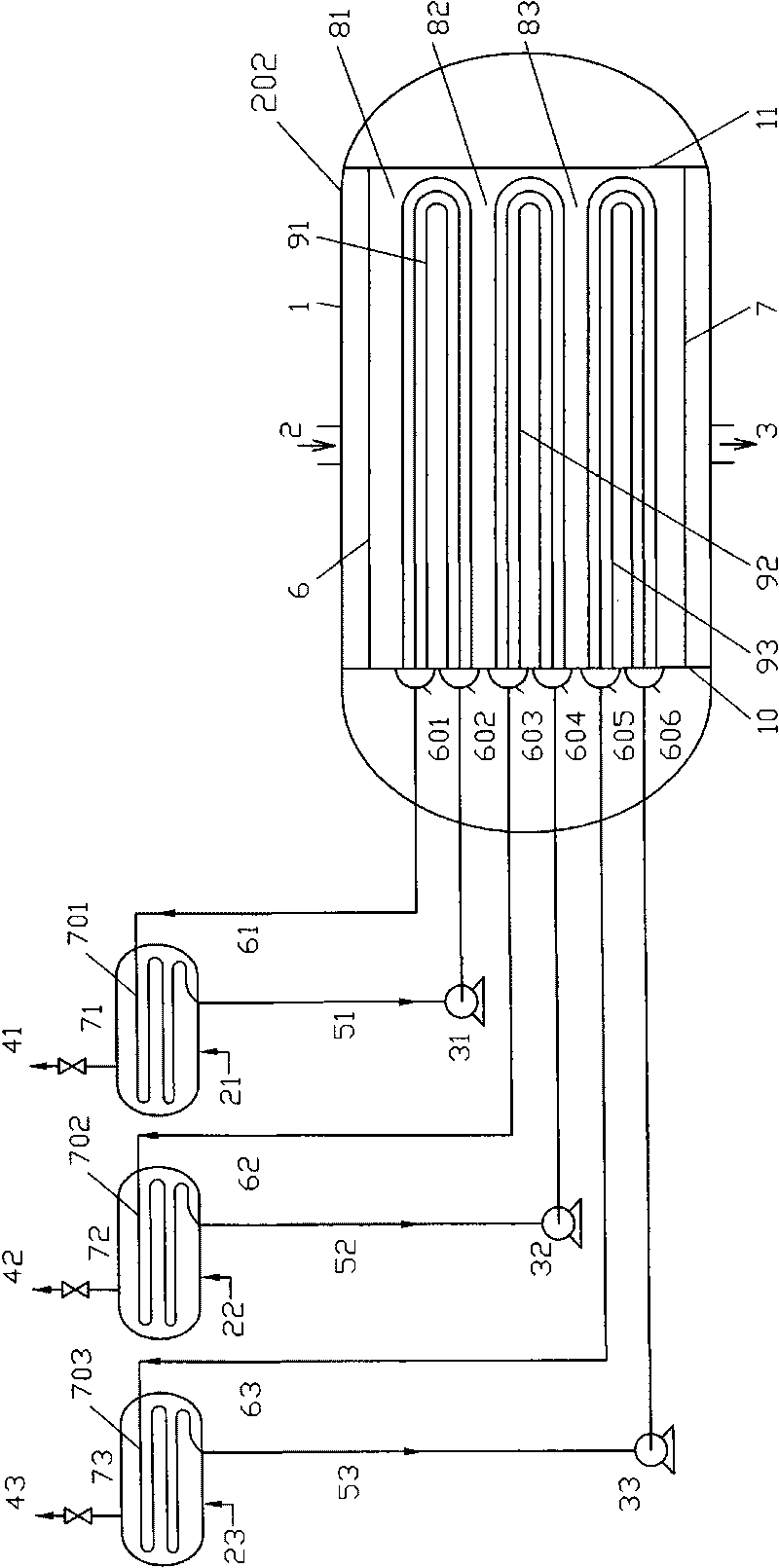

[0033] Embodiment 2: with containing H 2 O 20% crude methanol is used as raw material to make propylene but MTP, the production process is shown in figure 1 . Methanol dehydration reactor 201 is an air-cooled self-heating reactor with a diameter of 2 meters and a built-in γ-alumina catalyst of 20M 3 , the alkylation reactor 202 adopts image 3 The shown horizontal heat exchange reactor, with a diameter of 3.6 meters, contains SAPO-34MTP molecular sieve catalyst 120M 3 , the pressure is 0.2MPa, the methanol heated to 120°C enters the dehydration reactor 201, and dehydrates at a temperature of about 300°C through internal heat exchange. The heat is exchanged to 430°C and enters the hydrocarbonation reactor 202 to react at a temperature of 450-480°C, and the heat of reaction is absorbed by the molten salt (KNO 3 53%, NaNO 2 40%, NaNO 3 7%) absorption, the temperature difference between the hot spot temperature of the catalyst in the reaction zone and the temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com