Method and equipment for producing hydrocarbon with synthetic gas

A technology for synthesis gas and hydrocarbons, which is applied in the field of chemical engineering and can solve the problems of high energy consumption and heat insufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

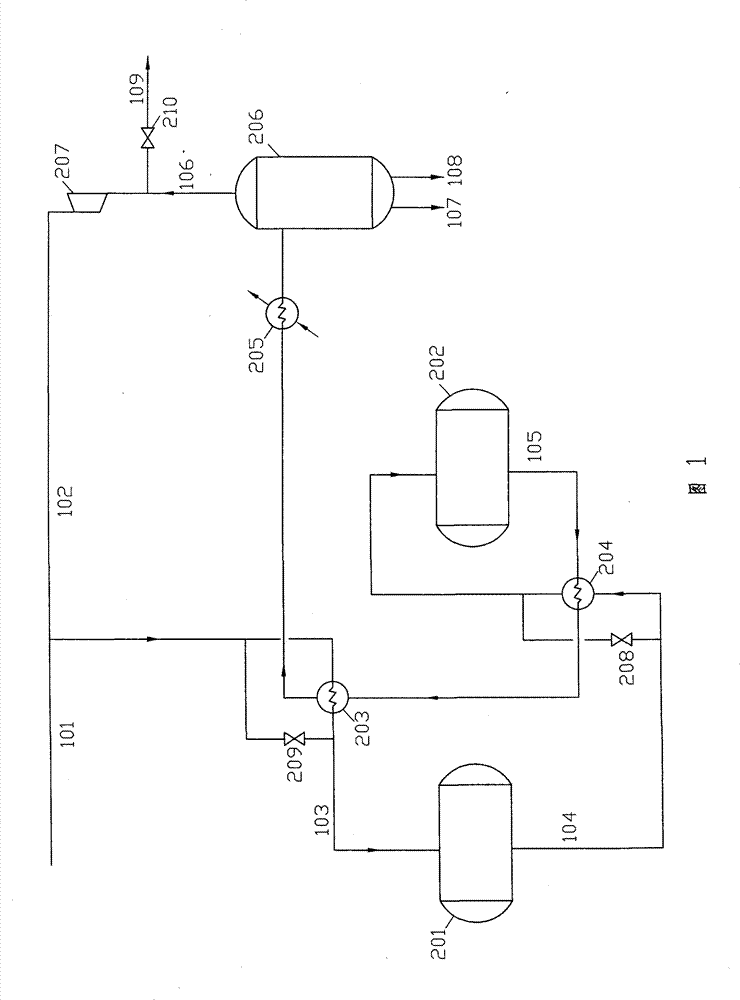

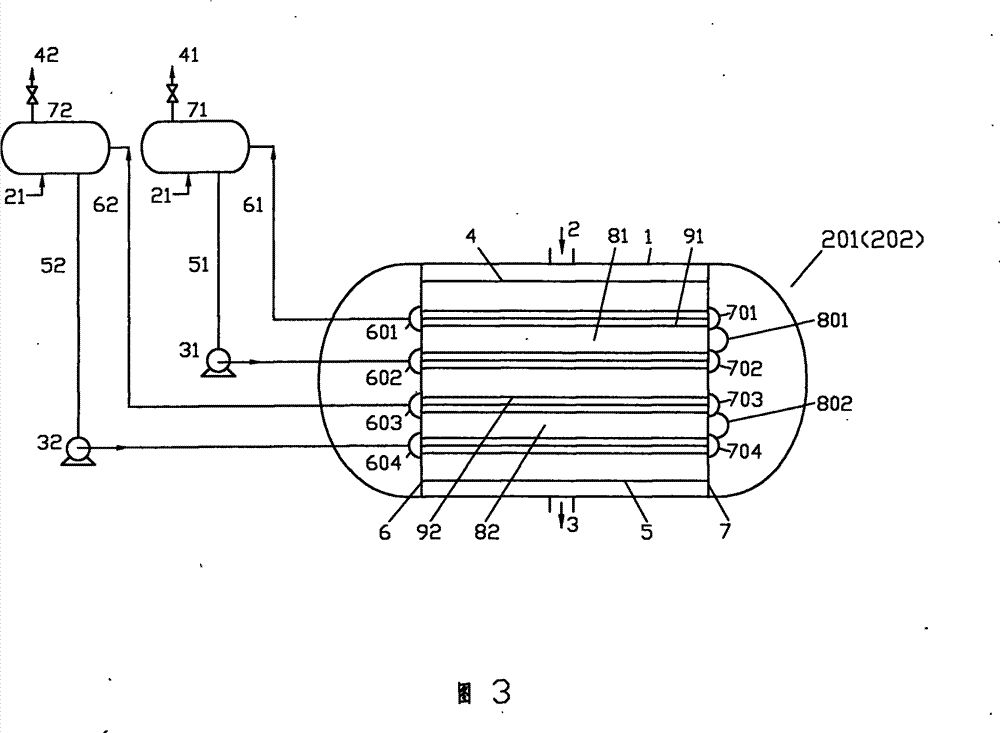

[0031] Embodiment 1: Gasoline production process with synthesis gas as figure 1 , the methanol synthesis reactor 201 adopts such as image 3 Horizontal graded water-cooling tower with a diameter of 4.0 meters and a built-in copper-based methanol catalyst of 150M 3 , the methanol dehydration reactor 202 adopts such as Figure 4 Horizontal water cooling tower with a diameter of 3.8 meters and an inner upper catalyst layer of 81 filled with γ-alumina 30M 3 , the middle and lower catalyst layers 82 and 83 are equipped with ZSM-5 molecular sieve catalyst 100M 3 , the synthesis gas compressed to 6 MPa merges with the recycle gas, and is heated to 230°C and enters the methanol synthesis reactor 201, and the methanol synthesis reaction is carried out on the methanol catalyst layer at a temperature of about 250°C. The heat of reaction is absorbed by the water in the horizontal water pipe in the synthesis tower to produce steam, the pressure of steam drum 71 is lower than the steam p...

Embodiment 2

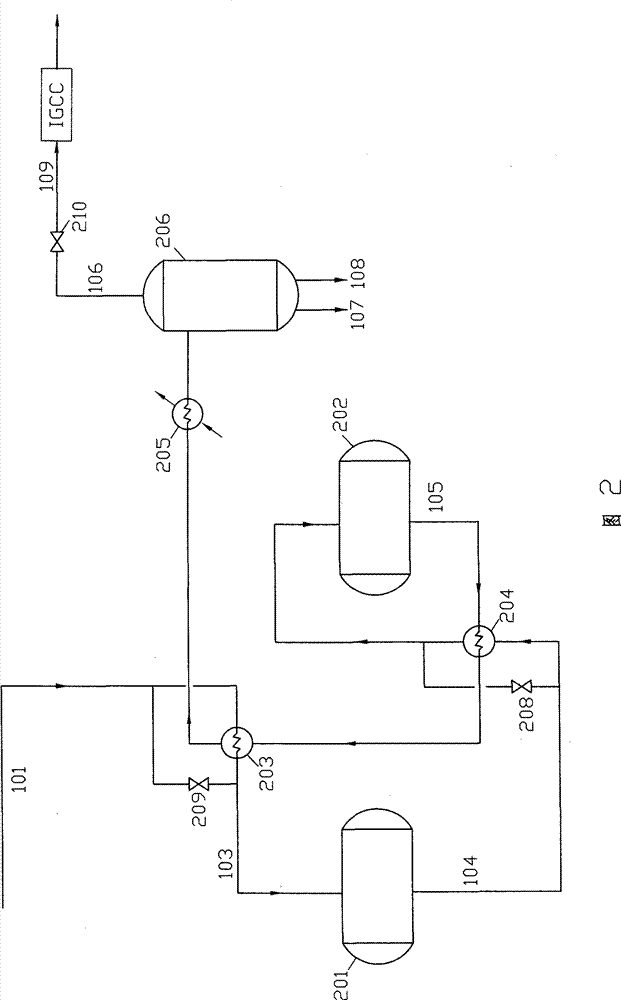

[0034] Embodiment 2: use syngas one-step method to make gasoline combined with IGCC production process see figure 2 , the methanol synthesis reactor 201 adopts such as image 3 Horizontal graded water-cooling tower with a diameter of 3.5 meters and a built-in copper-based methanol catalyst of 110M 3 , the methanol dehydration reactor 202 adopts such as image 3 Horizontal water-cooling tower with a diameter of 3.3 meters and a ZSM-5 molecular sieve catalyst of 90M 3 , the synthesis gas compressed to 5.5MPa is heated to 220°C and enters the methanol synthesis reactor 201, and the methanol synthesis reaction is carried out on the methanol catalyst layer at a temperature of about 250°C. The heat of reaction is absorbed by the water in the horizontal water pipe in the synthesis tower to by-produce steam, and the CH in the gas of methanol synthesis reactor 201 is released. 3 The OH content is 46%, and it exchanges heat with the methanol dehydration reactor 202 to 300°C and ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com