Vapor collecting device

A recovery device, steam technology, applied in the direction of special distribution devices, etc., can solve the problems of unevenness, non-adsorption of gasoline vapor, etc., and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

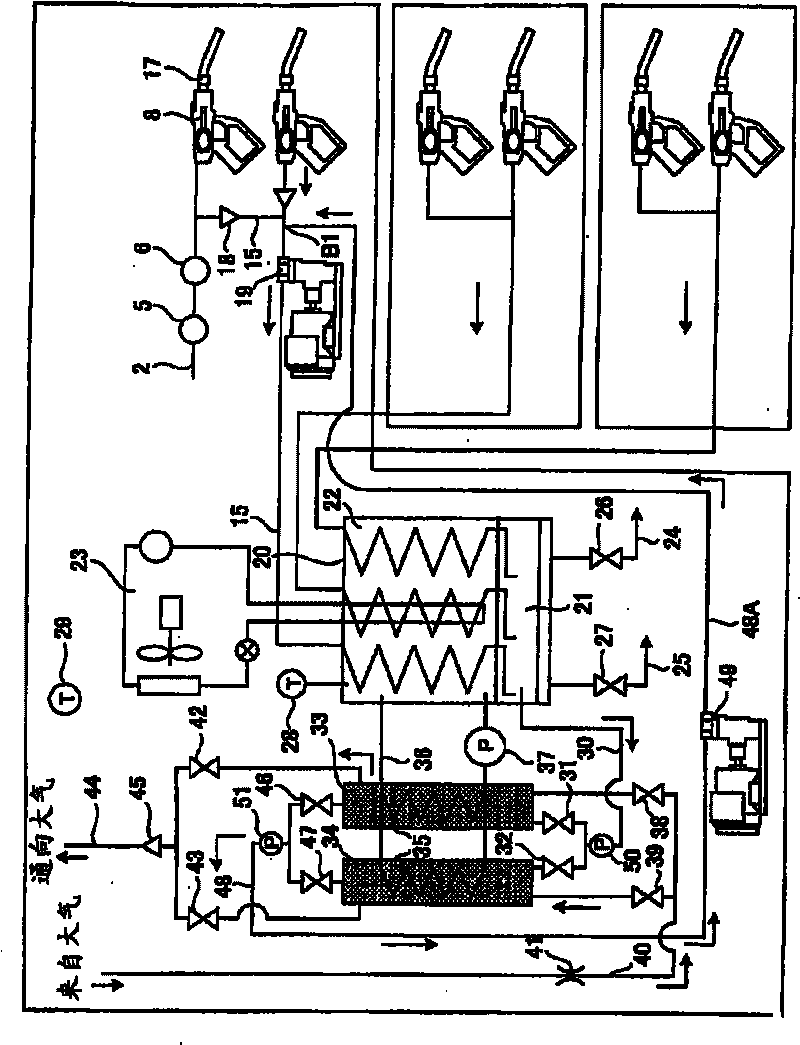

[0080] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0081] figure 1 It shows the whole of the gas station equipped with the vapor recovery device of the gas dispenser according to the present invention.

[0082] An oil storage tank 1 is buried underground in a gas station, and a filling pipe 2 connected to the oil storage tank 1 is arranged in a housing 4 of a fuel dispenser 3 .

[0083] Inside the housing 4 , a fuel pump 5 and a flow meter 6 are sandwiched between a fuel pipe 2 , and a fuel hose 7 is connected to the fuel pipe 2 .

[0084] A fuel nozzle 8 is provided at the tip of the fuel hose 7 . The fuel nozzle 8 is hung on a nozzle hanger 9 , and a nozzle switch 10 is provided on the nozzle hanger 9 . The nozzle switch 10 outputs an ON signal when the fuel nozzle leaves the nozzle hanger 9 .

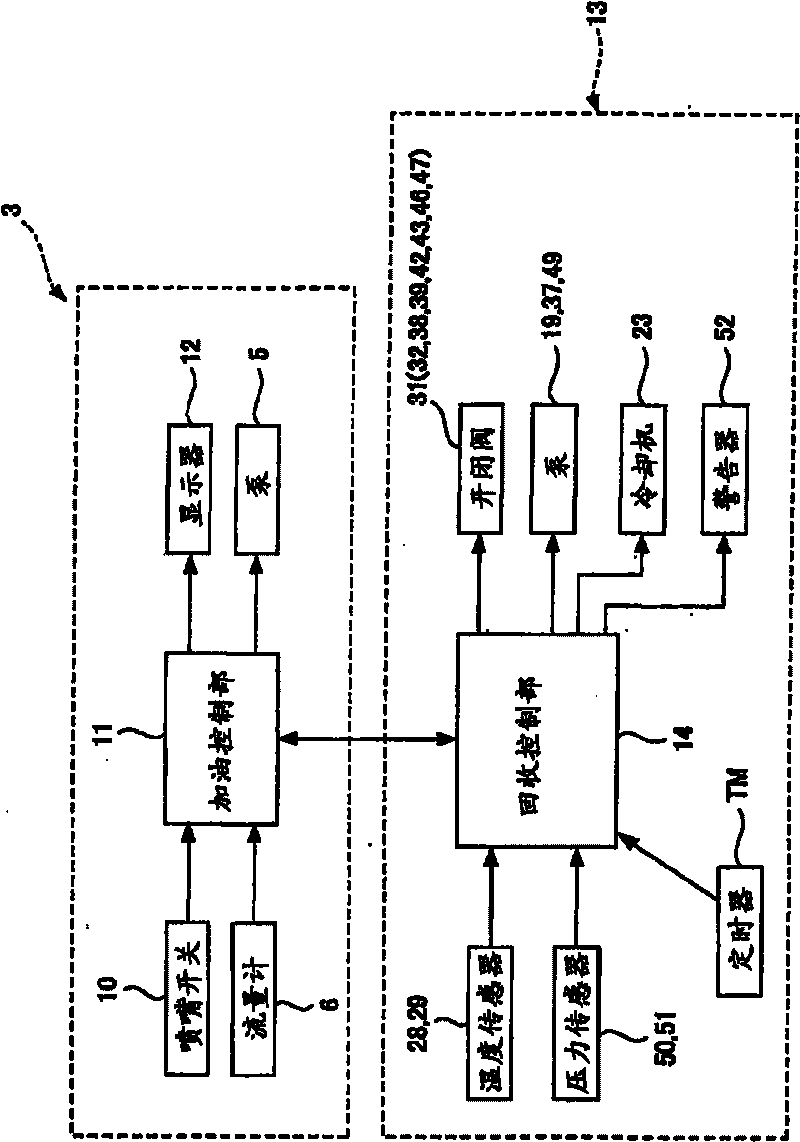

[0085] The fuel dispenser 3 is provided with a fuel control unit 11 .

[0086] The refueling control unit 11 receives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com