Robot automatic welding production line of middle groove and technological method thereof

A robot welding and automatic welding technology, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor welding quality, low work efficiency, and low production efficiency, and achieve complete and reasonable station settings and improve welding efficiency. Improvement of quality and welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

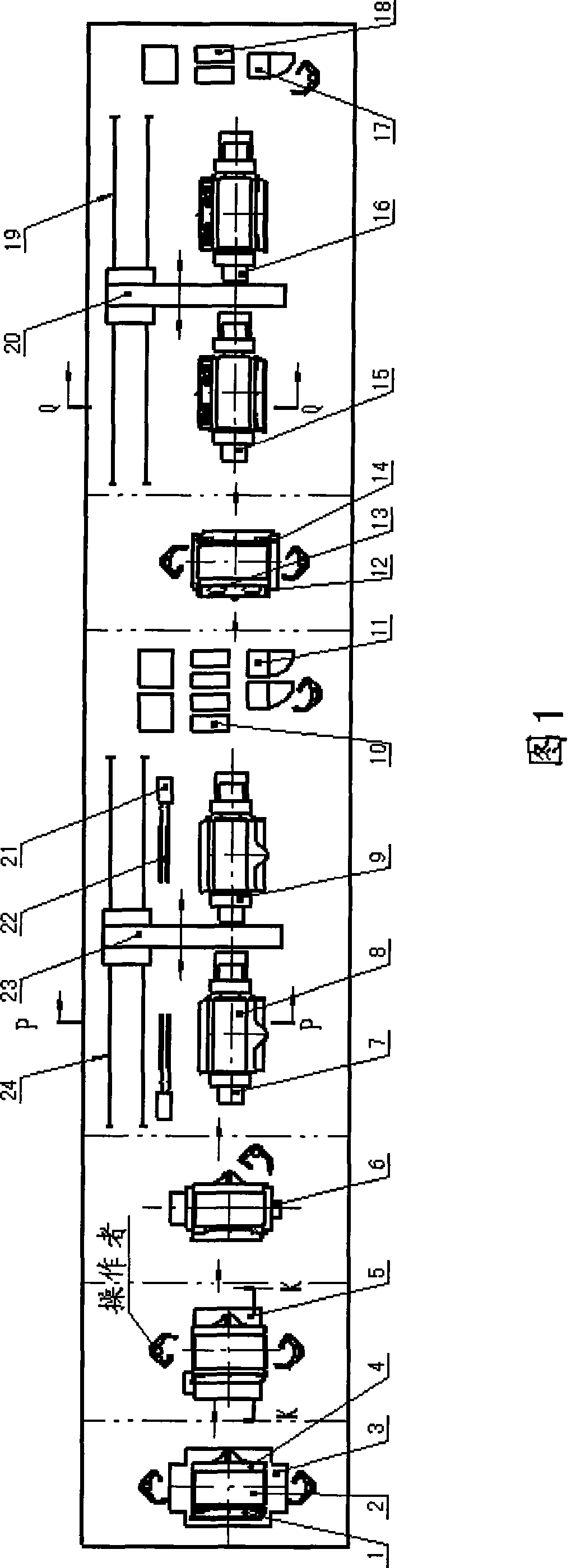

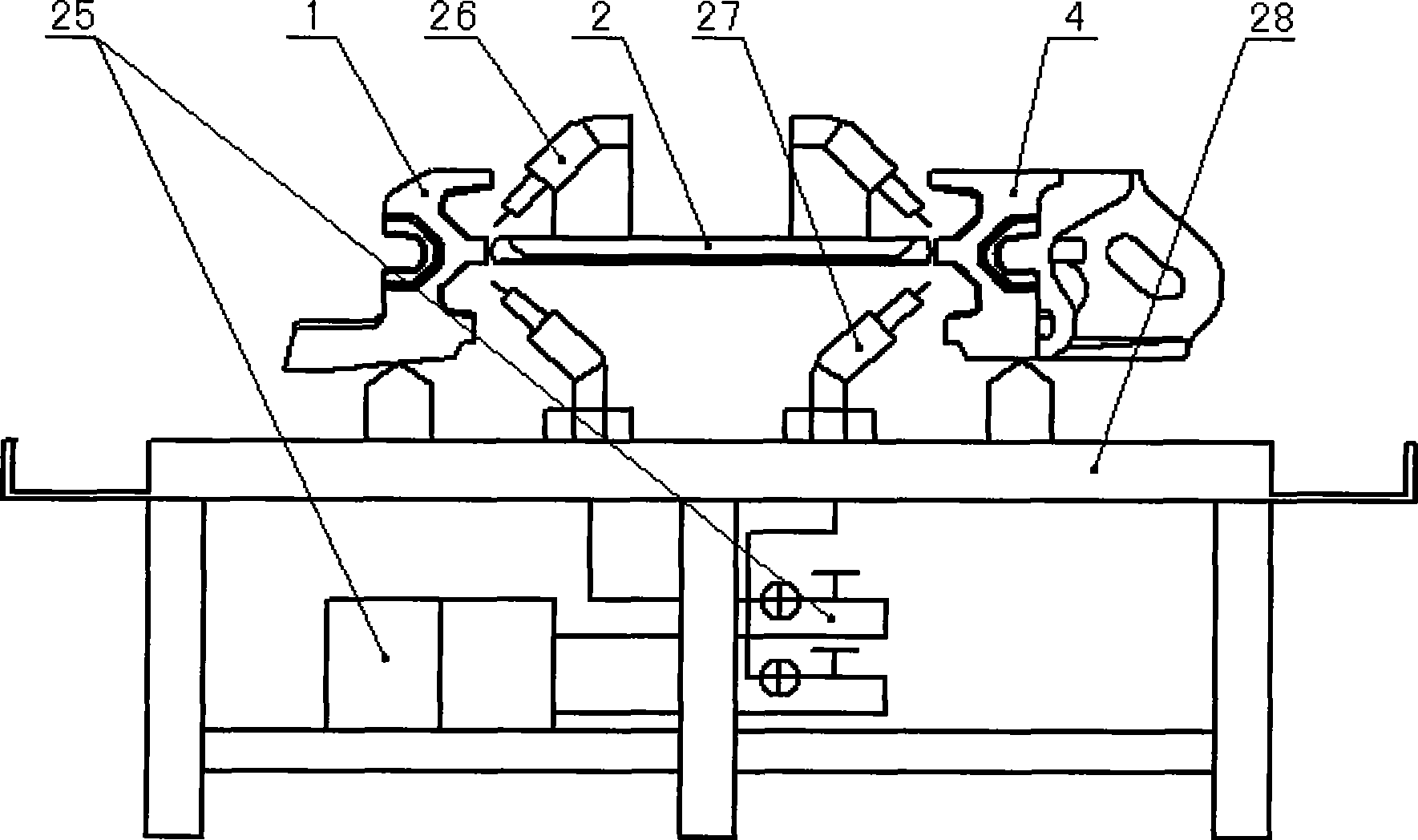

[0037] As can be seen from Fig. 1, the present invention designs 8 stations according to the manufacturing process direction of the middle tank and arranges them in a straight line, including the primary assembly station, the middle plate preheating station, the bottom welding station, the middle plate bottom plate robot welding workstation, the second There are 6 parts of the sub-assembly station and the bending plate rail seat robot welding workstation. The arrows indicate the logistics transfer direction of the workpiece, and the transfer of workpieces between each station is carried out by crane hoisting. The two workstations are controlled independently, using twin-wire digital double-pulse welding power supply. The robot, C-shaped frame, positioner, twin-wire elbow welding torch, and digital double-pulse welding power supply of each workstation are connected to the computer control system through their own cables. , controlled by a computer, can realize the automatic weld...

Embodiment 2

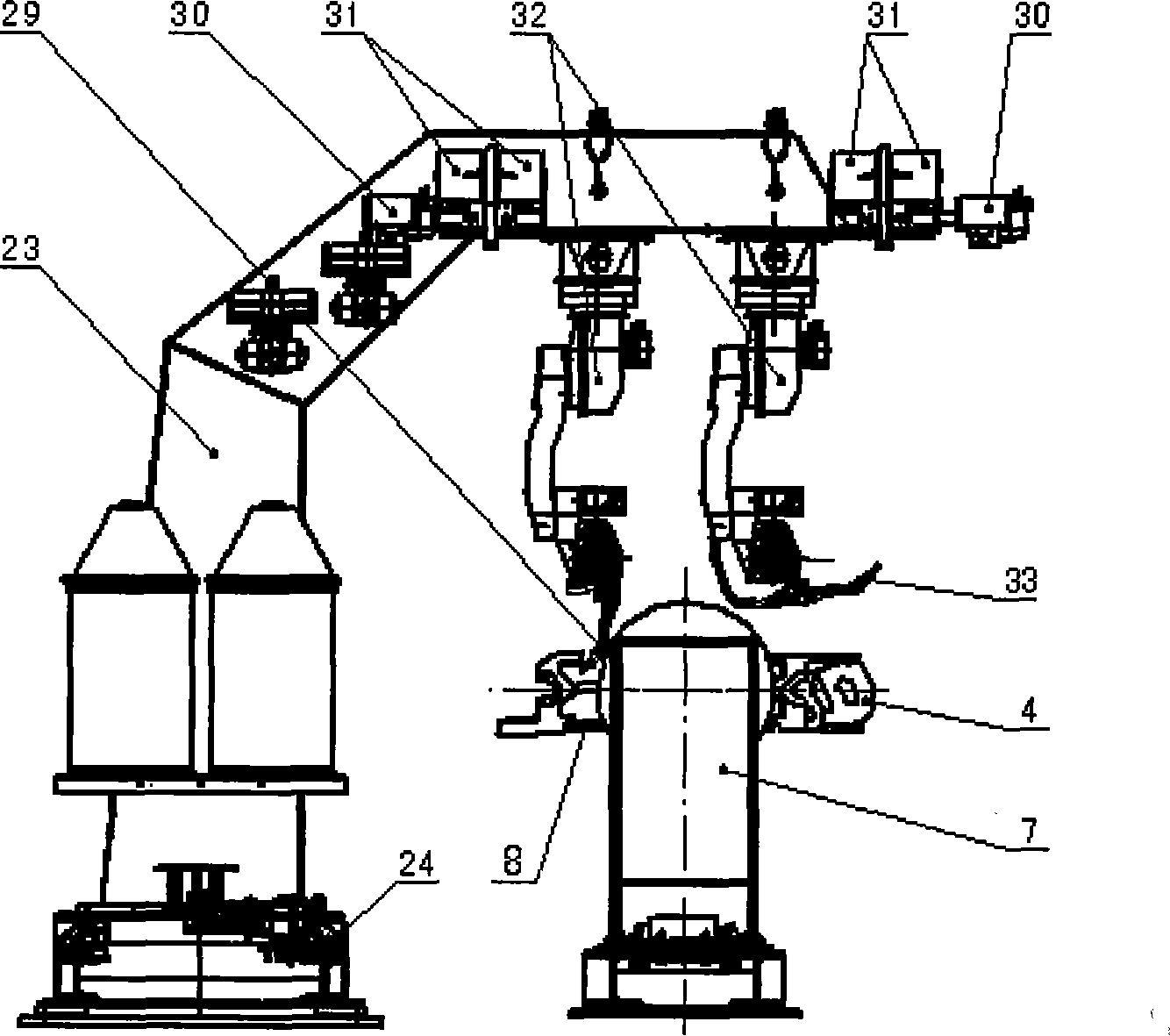

[0049] The difference between this embodiment and Embodiment 1 is that the bending plate rail seat robot welding workstation adopts another structural form, such as Figure 5 As shown, a set of horizontal guide rails 44 is installed on the side of the cross beam of the C-shaped frame 39, the robot 45 is side mounted on the horizontal guide rails, and can move laterally along the horizontal guide rails, and a single wire welding torch fixing frame is installed on one end of the frame cross beam 42. A single-wire elbow welding torch 40 with a contact welding seam starting position sensor installed on the head is clamped on this fixing frame, a double-wire welding torch fixing frame 46 is installed at the other end, and a contact welding torch is installed on the head. The double-wire elbow welding torch 47 of the type welding seam starting point positioning sensor is clamped on the fixture. Wire feeder 43 and welding torch cleaning device 41 are installed on the side of C-shaped...

Embodiment 3

[0052] The middle groove manufacturing process of the middle groove robot automatic welding production line is:

[0053] ①Primary assembly: Use the general assembly jig for the middle slot to manually assemble and point-align the blade groove side, middle plate, and baffle groove side at the primary assembly station, so that they have relatively correct positions to form components.

[0054] ② Middle plate preheating: transport the above components to the fixed high-efficiency flame preheating device for the middle plate at the second station, and perform flame preheating on the middle plate. The preheating temperature of the middle plate is controlled at 150-175°C to achieve After the temperature is reached, the flame will be automatically turned off by the flame control system.

[0055] ③ Bottom welding of the middle plate: When the workpiece error is large, so that the single-sided butt gap between the middle plate and the groove side is >2mm, the preheated components are i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com