Near-net-shape method for porous metal part

A near-net-shaping, porous metal technology, applied in the field of rapid prototyping technology and powder loose-pack sintering composite forming, can solve the problems that affect the dimensional accuracy of parts, difficult to directly form parts, and cannot be directly formed, so as to avoid dimensional deviation and avoid Machining, avoiding the effect that the porosity is not easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

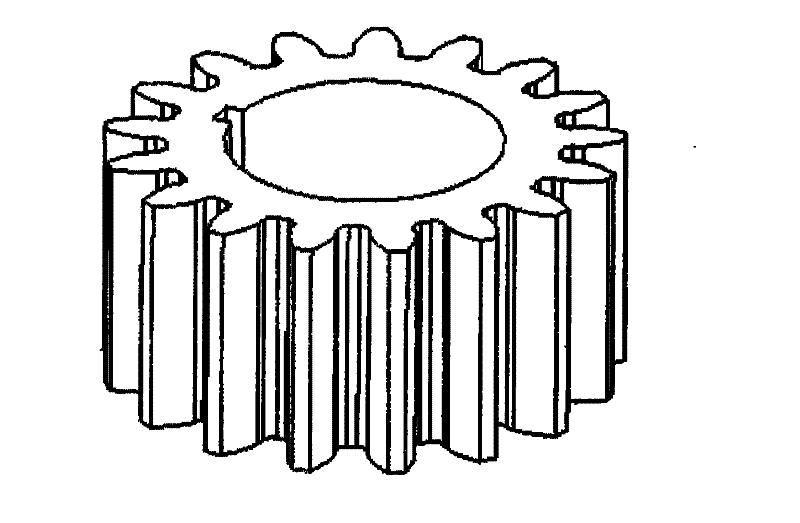

Image

Examples

example 1

[0035] (1) Use 3D modeling software (such as UG, Pro / E, etc.) to design the CAD 3D model of the porous part, then process it with the slicing software and save it as an STL file, and input the data information of the STL file to the SLM rapid prototyping equipment.

[0036] (2) Spread a layer of 316L stainless steel powder with a thickness of about 0.1-0.2mm on the metal substrate by the powder feeding mechanism. The particle size of the stainless steel powder is about 10-100 μm, and the powder contains 10wt% methylcellulose as a loosening agent .

[0037] When methyl cellulose is used as the bulking agent, its addition can generally be 5-40 wt%.

[0038] (3) A YAG laser or a fiber laser with a laser power of 100 W is used to scan the boundary of the slice contour and melt the powder at the boundary, wherein the scanning speed is 150 mm / s.

[0039] (4) Repeat the above steps (2)-(3) until the shell processing of the entire part is completed. At this time, the metal shell is t...

example 2

[0044] (1) Use 3D modeling software (such as UG, Pro / E, etc.) to design the CAD 3D model of the porous part, then process it with the slicing software and save it as an STL file, and input the data information of the STL file to the SLM rapid prototyping equipment.

[0045] (2) Spread a layer of iron powder with a thickness of about 0.1-0.2 mm on the metal substrate by the powder feeding mechanism, the powder particle size is about 10-100 μm, and boric acid is contained as a loosening agent in an amount of 2 wt%.

[0046] When boric acid is used as the loosening agent, its addition amount can generally be 1-4wt%.

[0047] (3) A YAG laser or a fiber laser with a laser power of 100 W is used to scan the boundary of the slice contour and melt the powder at the boundary, wherein the scanning speed is 100 mm / s.

[0048] (4) Repeat steps (2)-(3) until the iron shell with a certain shape is processed, a small hole is left on the upper part of the iron shell, and the loose powder insi...

example 3

[0053] (1) Use 3D modeling software (such as UG, Pro / E, etc.) to design the CAD 3D model of the porous part, then process it with the slicing software and save it as an STL file, and input the data information of the STL file to the SLM rapid prototyping equipment.

[0054] (2) Spread a layer of iron powder with a thickness of about 0.1-0.2mm on the metal substrate by the powder feeding mechanism.

[0055] (3) A YAG laser or a fiber laser with a laser power of 100 W is used to scan the boundary of the slice contour and melt the powder at the boundary, wherein the scanning speed is 140 mm / s.

[0056] (4) Repeat steps (2)-(3) until the iron shell with a certain shape is processed, a small hole is left on the upper part of the iron shell, and the loose powder inside is poured out. At this time, the iron shell is for subsequent loose packing and sintering mold required.

[0057] (5) Fill the iron shell with Ti powder, which is used for subsequent loose-pack sintering.

[0058] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com