Gas Sampling Dust Water Oil Automatic Separation Device

An automatic separation and gas technology, applied in sampling devices and other directions, can solve problems such as abnormal signals, and achieve the effects of high reliability, avoidance of secondary pollution, and convenient installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

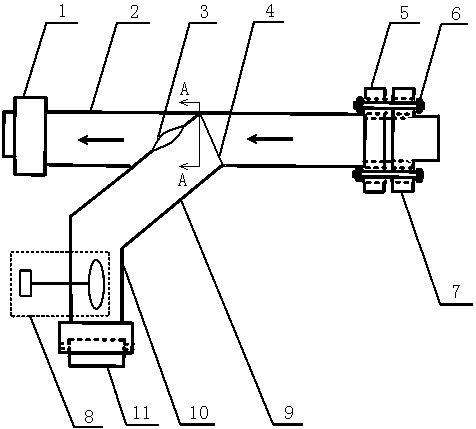

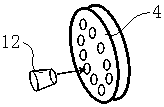

[0021] Such as figure 1 , 2 , 3, a gas sampling dust-water-oil automatic separation device, comprising a horizontal main section 2, one end of the horizontal main section 2 is a sampling pipe inlet 1, and the other end of the horizontal main section 2 is a blast furnace gas interface 5, said The horizontal main pipe section 2 is connected with a separation inclined pipe 9, and the separation inclined pipe 9 is obliquely inserted into the horizontal main pipe section 2 from below; The axis is at an acute angle, and the entrance of the separation inclined pipe 9 is provided with a deceleration flap 4, and the deceleration flap 4 is evenly distributed with downwardly inclined gradually expanding air holes 12, and the separation inclined pipe 9 is located at the outlet straight pipe section 2 A clean gas outlet 3 is provided on the inner side wall.

[0022] In this embodiment, the gradually expanding air holes 12 are frustum-shaped air holes.

[0023] In order to avoid secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com