Duplex-bearing self-adjusting aligning web plate type round vibrating screen

A double-bearing, circular vibrating screen technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of difficult disassembly and maintenance, unreasonable force on the screen, small heat dissipation area, etc., and achieves easy disassembly and maintenance. The bearing life is easy to guarantee and the effect of increasing the heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

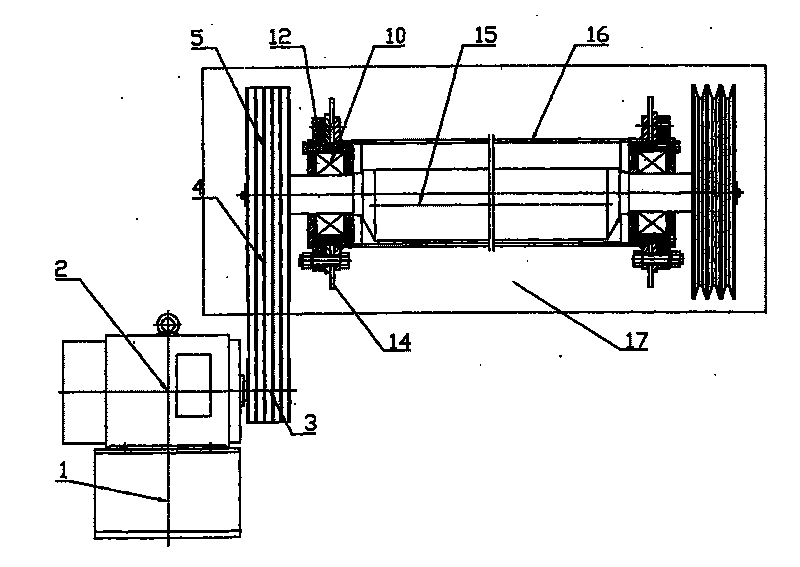

[0018] A double-bearing self-adjusting and centering web-type circular vibrating screen, including a fixed bracket (1), a common motor (2), an eccentric device and a bearing chamber (12), a pulley device connected to the common motor (2), and the pulley device and The intermediate transmission device (6) is connected, the intermediate transmission device (6) is connected with the eccentric device through the flexible coupling (7), and the eccentric device is connected with the bearing chamber (12) through the cardan transmission shaft (11); the pulley The device is composed of a large pulley (5), a small pulley (3) and a V-shaped belt (4); the eccentric device is composed of a self-aligning bearing (10), an eccentric block (9) and a shaft head flange (8); A web-type vibrator (13) is arranged under the bearing chamber (12); the lower end of the eccentric device is connected to the bottom of the web-type vibrator (13) through a screen side (14). The above-mentioned double-bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com