Core-shell type aromatic conversion catalyst, preparation method and application thereof

A catalyst and core-shell type technology, which is applied in the field of core-shell aromatics conversion catalysts and its preparation, can solve the problems of strong acidity on the outer surface of molecular sieve catalysts, fast deactivation speed, and low selectivity of aromatics shape-selective catalysts, so as to reduce product Effects of carbon deactivation rate, acid density reduction, and catalyst selectivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

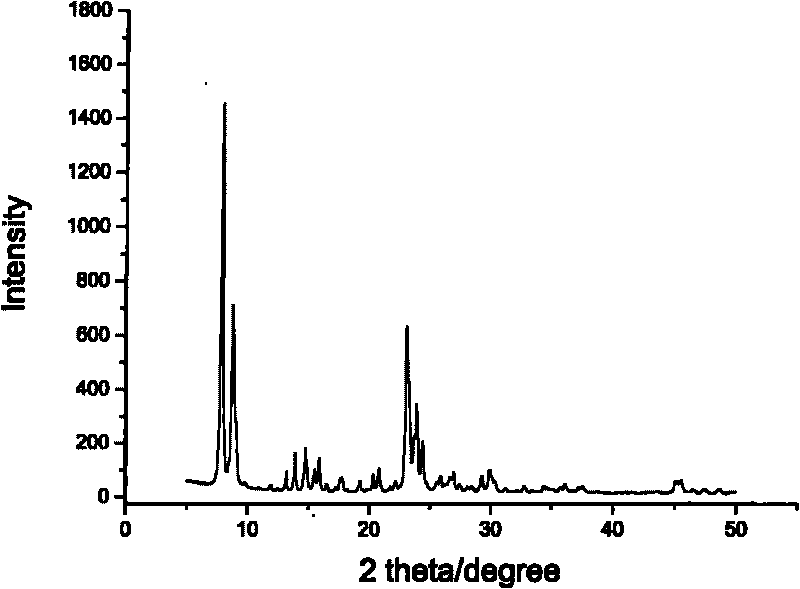

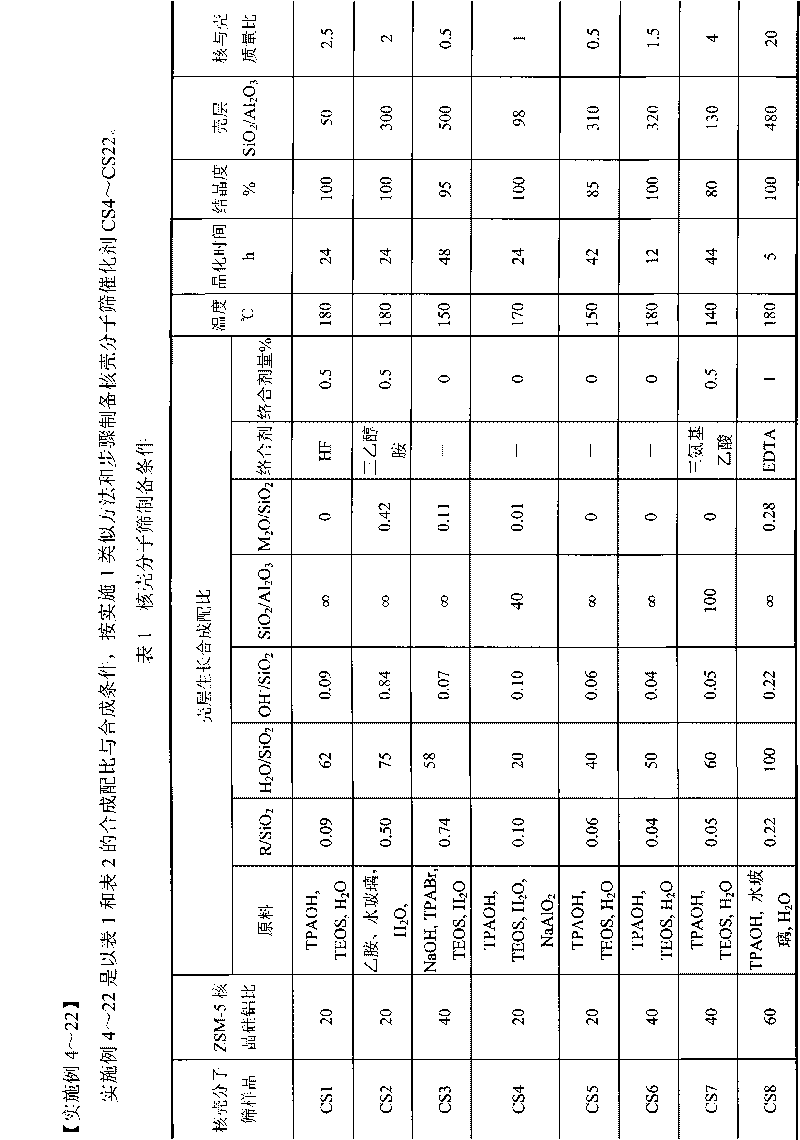

[0019] Mix 10 grams of 25% by weight TPAOH aqueous solution, 28 grams of tetraethyl orthosilicate, and 140 grams of water, add 1 ml of 35% (weight) HF acid aqueous solution, stir for 4 hours, and then add 20 grams of SiO 2 / Al 2 o 3 20 ZSM-5 nuclear phase molecular sieves were put into a 1-liter stainless steel crystallization kettle with stirring, sealed, heated to 180°C, and crystallized at a constant temperature for 1 day, with a stirring speed of 100 rpm. At the end of crystallization, quench the solid product, filter the solid product, wash until the pH of the washing solution is 7, dry at 110°C overnight, and then bake in a muffle furnace at 550°C for 4 hours to obtain the core-shell molecular sieve CS1. The shell SiO 2 / Al 2 o 3 After analysis, it was found to be 300, and the core-shell ratio was 2.5. Its X-ray diffraction characterization pattern is shown in the attached figure 1 .

[0020] The core-shell molecular sieve CS1 is added to a 10% by weight ammonium ...

Embodiment 2

[0023] 1.3 grams of ethylamine, 13.5 grams of water glass (containing SiO 2 25.8 wt%, Na 2 O 7.3% by weight) mixed with 70 grams of water, added 2 milliliters of triethanolamine, stirred for 1 hour, then added 7 grams of SiO 2 / Al 2 o 3 20 ZSM-5 nuclear phase molecular sieves were put into a 100 ml stainless steel crystallization kettle, sealed, heated to 180°C, and crystallized at constant temperature for 1 day. At the end of the crystallization, quench the solid product, filter, wash, and dry overnight at 110°C to obtain the core-shell molecular sieve CS2, and the shell SiO 2 / Al2 o 3 The molar ratio was analyzed to be 50 and the core / shell weight ratio was 2:1.

[0024] After ion-exchanging the core-shell molecular sieve CS2 according to the method described in Example 1, the core-shell molecular sieve CS2 and Al 2 o 3 Binders were mixed, stirred and kneaded, extruded into rods, dried in the air and calcined in a muffle furnace at 550°C for 4 hours to obtain the cor...

Embodiment 3

[0026] Mix 2.6 grams of TPABr, 0.4 grams of sodium hydroxide, 28 grams of ethyl orthosilicate, and 140 grams of water, add 0.5 grams of NaBr, stir for 8 hours, and then add 8 grams of SiO 2 / Al 2 o 3 It is a 40-nuclear phase molecular sieve ZSM-5, put it into a 1-liter stainless steel crystallization kettle with stirring, seal it, raise the temperature to 150°C, and crystallize at a constant temperature for 2 days at a stirring speed of 200 rpm. At the end of the crystallization, quench the solid product, filter, wash, and dry overnight at 110°C to obtain a core-shell molecular sieve CS3 with a core / shell ratio of 2.5:1, and the shell SiO 2 / Al 2 o 3 The molar ratio was 500.

[0027] After ion-exchanging the core-shell molecular sieve CS3 according to the method described in Example 1, the core-shell molecular sieve CS3 and TiO 2 Binders were mixed, stirred and kneaded, extruded into rods, dried in the air and calcined in a muffle furnace at 550°C for 4 hours to obtain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com