An ultra-light anti-static floor

An anti-static floor, ultra-light technology, applied to objects with hollow walls, other household appliances, floors, etc., can solve the problems of poor hardness, poor wear resistance, unstable conductivity, etc., and achieve a simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

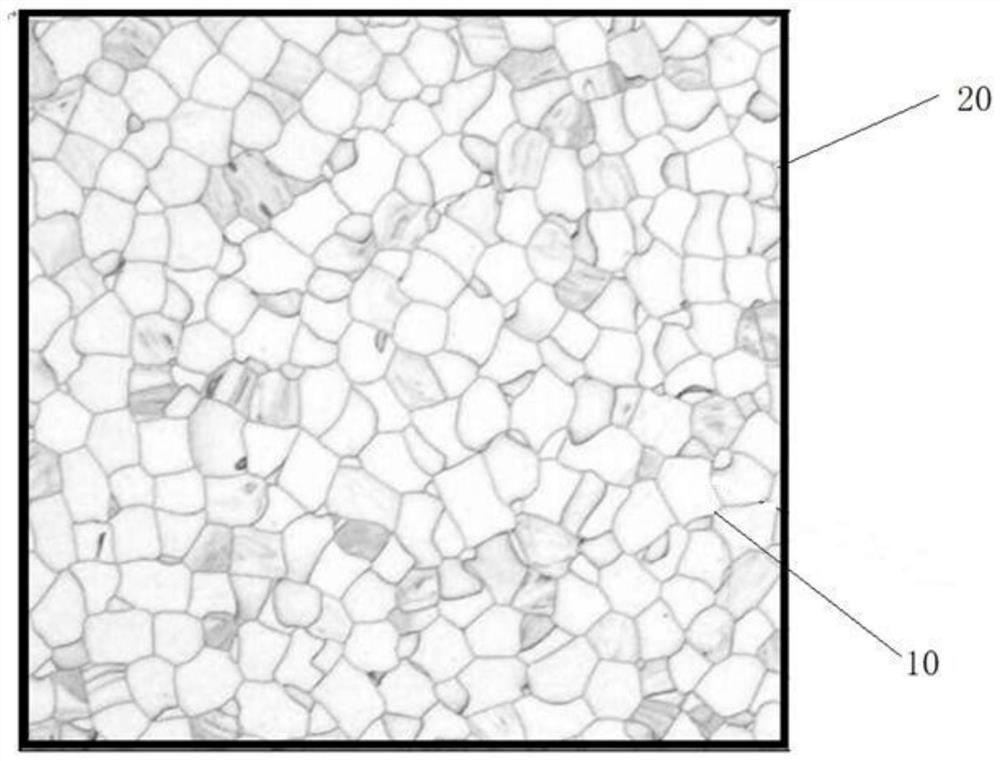

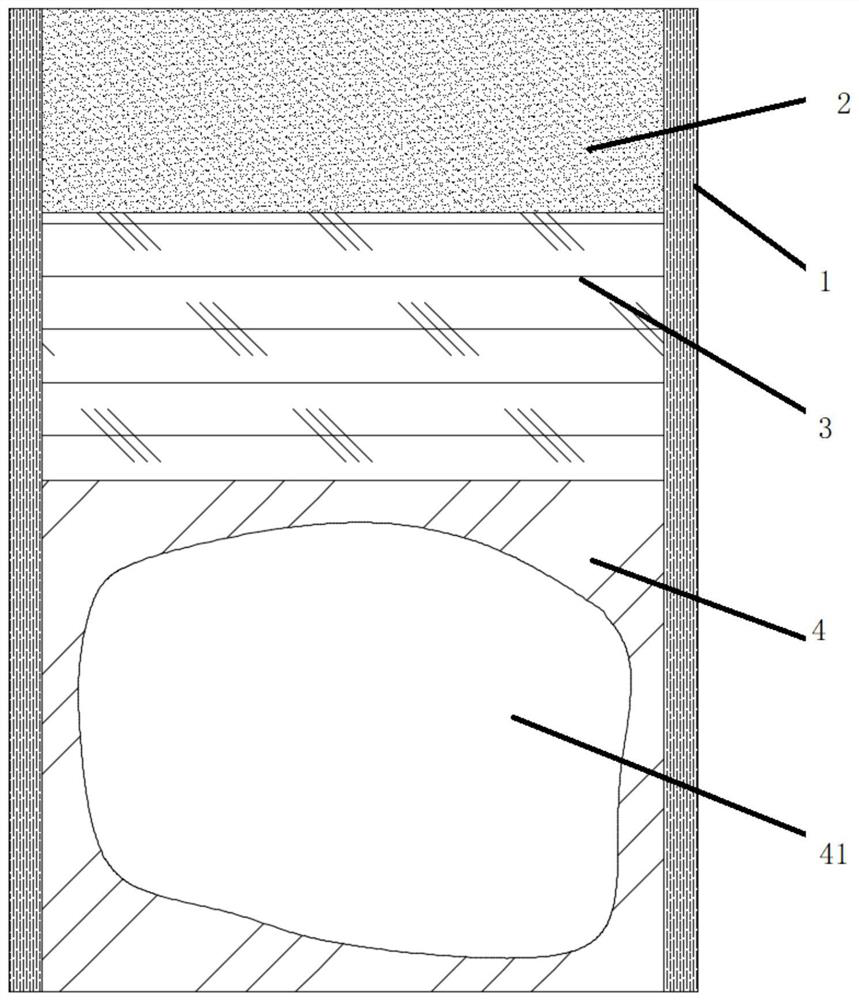

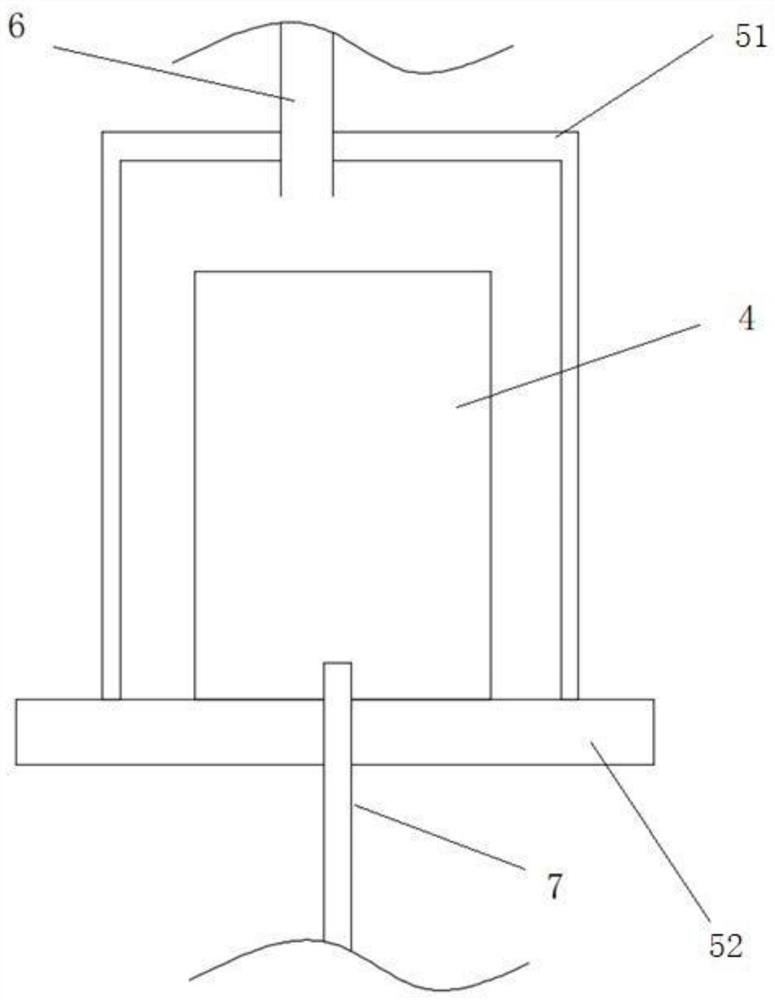

[0037] An ultra-light anti-static floor, including a square anti-static floor in the middle, and edge elastic strips located on four sides of the anti-static floor; the anti-static floor is formed by heating and extruding a plurality of anti-static particles, the The antistatic particles all include an outer conductive coating 1, and a floor body located in the conductive coating 1, the floor body includes an upper layer 2 of wooden blocks, an elastic layer 3 and a lower layer 4 of PVC connected sequentially from top to bottom, The PVC lower layer 4 is provided with a cavity inside.

[0038] - The conductive coating 1 is made of carbon fiber and metal powder in a weight ratio of 1:1.

[0039] - The elastic layer 3 is made of thermoplastic polyurethane foam particles.

[0040] -The PVC lower layer 4 is made of the following parts by weight: 75 parts of PVC, 4 parts of calcium carbonate, 2 parts of stabilizer, 0.1 part of plasticizer, 0.1 part of lubricant, 10 parts of lignocel...

Embodiment 2

[0056] An ultra-light anti-static floor, including a square anti-static floor in the middle, and edge elastic strips located on four sides of the anti-static floor; the anti-static floor is formed by heating and extruding a plurality of anti-static particles, the The antistatic particles all include an outer conductive coating 1, and a floor body located in the conductive coating 1, the floor body includes an upper layer 2 of wooden blocks, an elastic layer 3 and a lower layer 4 of PVC connected sequentially from top to bottom, The PVC lower layer 4 is provided with a cavity inside.

[0057] - The conductive coating 1 is made of carbon fiber and metal powder in a weight ratio of 1:1.

[0058] - The elastic layer 3 is made of thermoplastic polyurethane foam particles.

[0059] -The PVC lower layer 4 is made of the following parts by weight, 80 parts of PVC, 6 parts of calcium carbonate, 2.5 parts of stabilizer, 0.3 part of plasticizer, 0.3 part of lubricant, 12 parts of lignoc...

Embodiment 3

[0075] An ultra-light anti-static floor, including a square anti-static floor in the middle, and edge elastic strips located on four sides of the anti-static floor; the anti-static floor is formed by heating and extruding a plurality of anti-static particles, the The antistatic particles all include an outer conductive coating 1, and a floor body located in the conductive coating 1, the floor body includes an upper layer 2 of wooden blocks, an elastic layer 3 and a lower layer 4 of PVC connected sequentially from top to bottom, The PVC lower layer 4 is provided with a cavity inside.

[0076] - The conductive coating 1 is made of carbon fiber and metal powder in a weight ratio of 1:1.

[0077] - The elastic layer 3 is made of thermoplastic polyurethane foam particles.

[0078] -The PVC lower layer 4 is made of the following parts by weight: 85 parts of PVC, 8 parts of calcium carbonate, 3 parts of stabilizer, 0.5 part of plasticizer, 0.5 part of lubricant, 15 parts of lignocel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com