A kind of wooden antistatic floor and its preparation process

An anti-static floor and preparation technology, which is applied to floors, coverings/linings, buildings, etc., can solve the problems of poor floor texture, etc., and achieve the effect of simple preparation process and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

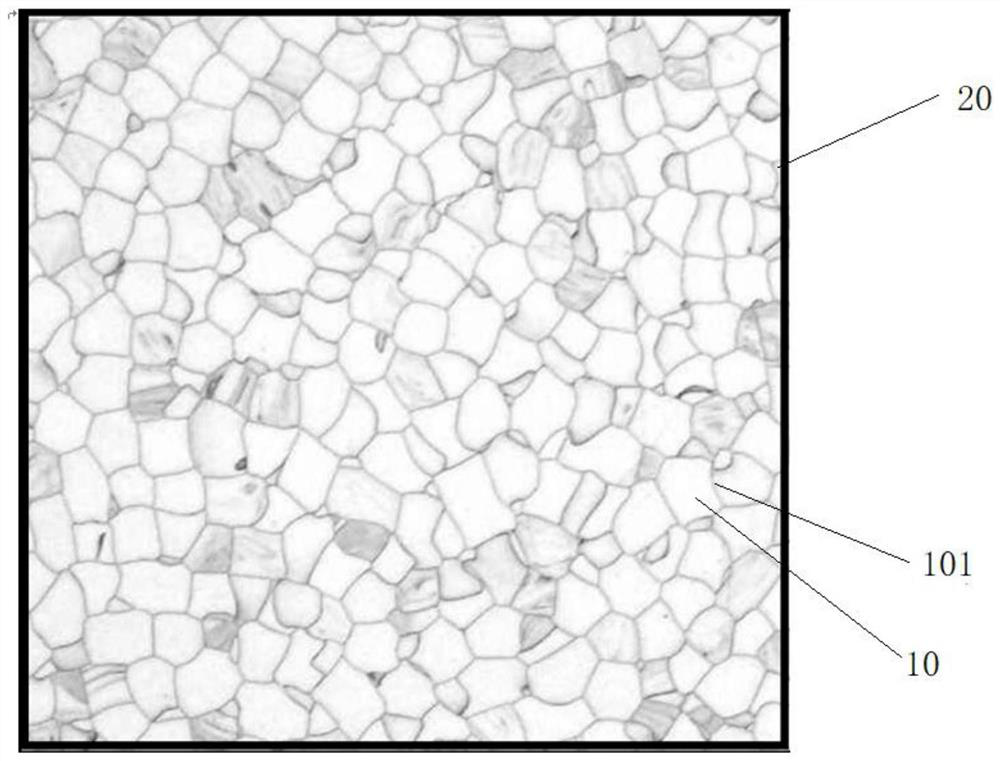

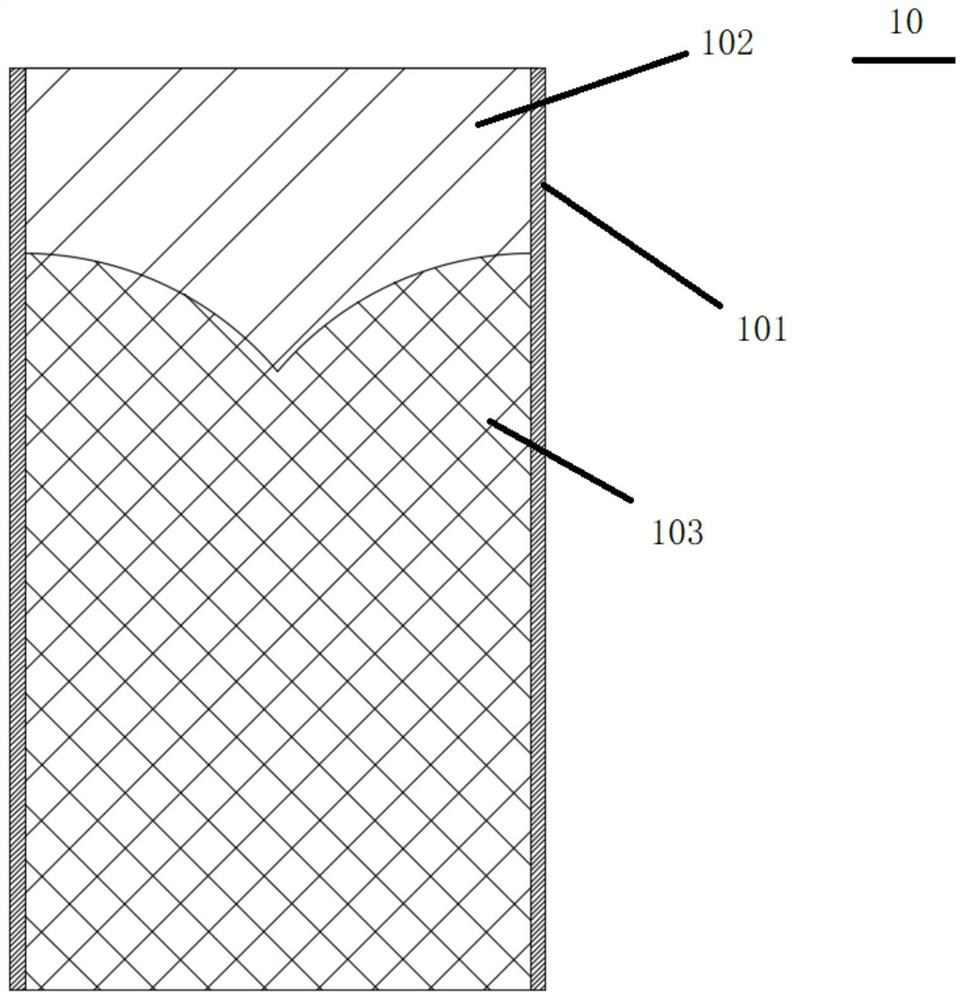

[0035] A wooden anti-static floor, comprising a square anti-static floor in the middle, and edge elastic strips located on four sides of the anti-static floor; the anti-static floor is formed by heating and extruding a plurality of conductive particles, and the conductive particles are all It includes an outer conductive coating 101 and floor particles inside the conductive coating 101 . The floor particles include an upper layer 102 of wooden blocks and a lower layer 103 of PVC connected up and down. The main body of the floor in the middle is generally 60*60cm, and its thickness is 3mm. The edge elastic strips are arranged on the four sides of the anti-static floor, and its thickness is 2mm. After installing the edge elastic strips, the anti-static floor can be installed more conveniently. , to accommodate the dimensional error between each plate.

[0036] The preparation process of above-mentioned wooden antistatic floor is as follows:

[0037] S1. Preparation of PVC lower...

Embodiment 2

[0051] A wooden anti-static floor, comprising a square anti-static floor in the middle, and edge elastic strips located on four sides of the anti-static floor; the anti-static floor is formed by heating and extruding a plurality of conductive particles, and the conductive particles are all It includes an outer conductive coating 101 and floor particles inside the conductive coating 101 . The floor particles include an upper layer 102 of wooden blocks and a lower layer 103 of PVC connected up and down. The main body of the floor in the middle is generally 60*60cm, and its thickness is 3mm. The edge elastic strips are arranged on the four sides of the anti-static floor, and its thickness is 2mm. After installing the edge elastic strips, the anti-static floor can be installed more conveniently. , to accommodate the dimensional error between each plate.

[0052] The preparation process of above-mentioned wooden antistatic floor is as follows:

[0053]S1. Preparation of PVC lower ...

Embodiment 3

[0067] A wooden anti-static floor, comprising a square anti-static floor in the middle, and edge elastic strips located on four sides of the anti-static floor; the anti-static floor is formed by heating and extruding a plurality of conductive particles, and the conductive particles are all It includes an outer conductive coating 101 and floor particles inside the conductive coating 101 . The floor particles include an upper layer 102 of wooden blocks and a lower layer 103 of PVC connected up and down. The main body of the floor in the middle is generally 60*60cm, and its thickness is 3mm. The edge elastic strips are arranged on the four sides of the anti-static floor, and its thickness is 2mm. After installing the edge elastic strips, the anti-static floor can be installed more conveniently. , to accommodate the dimensional error between each plate.

[0068] The preparation process of above-mentioned wooden antistatic floor is as follows:

[0069] S1. Preparation of PVC lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com