Heat accumulation type condenser using shape-stabilized phase-change material

A technology of shape-setting phase change materials and condensers, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of low production cost, poor contact between the condenser tube and the refrigerator wall, and achieve energy storage utilization High efficiency, large latent heat of phase change, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

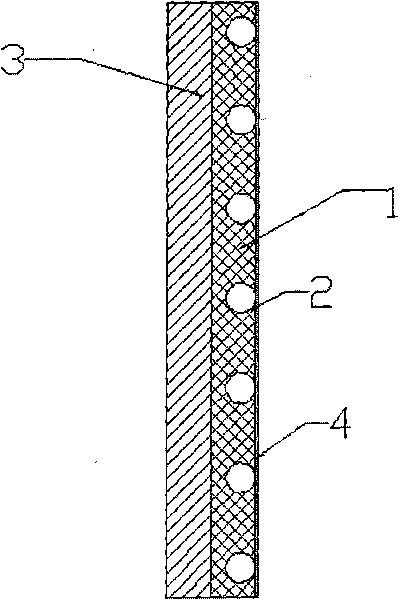

[0024] The thermal storage material in this embodiment is a fixed phase change material, combined with figure 1 illustrate: figure 1 Among them, 1 is a fixed phase change material, 2 is a condensation pipe, 3 is a refrigerator insulation material, and 4 is a refrigerator box wall. The shape-setting phase change material has properties such as high thermal conductivity, adjustable phase change temperature, large latent heat of phase change, solid state of the material before and after the phase change, no leakage, and no need for packaging.

[0025] In this embodiment, the structure of the heat exchanger: the condensation pipe 2 is in direct contact with the refrigerator wall 4, the shape-setting phase change material 1 completely surrounds the condensation pipe 2, and the shape-setting phase change material 1 fixes the condensation pipe 2 on the refrigerator insulation material 3 Phase change between 4 and refrigerator.

[0026] In this embodiment, the thermal conductivity...

Embodiment 2

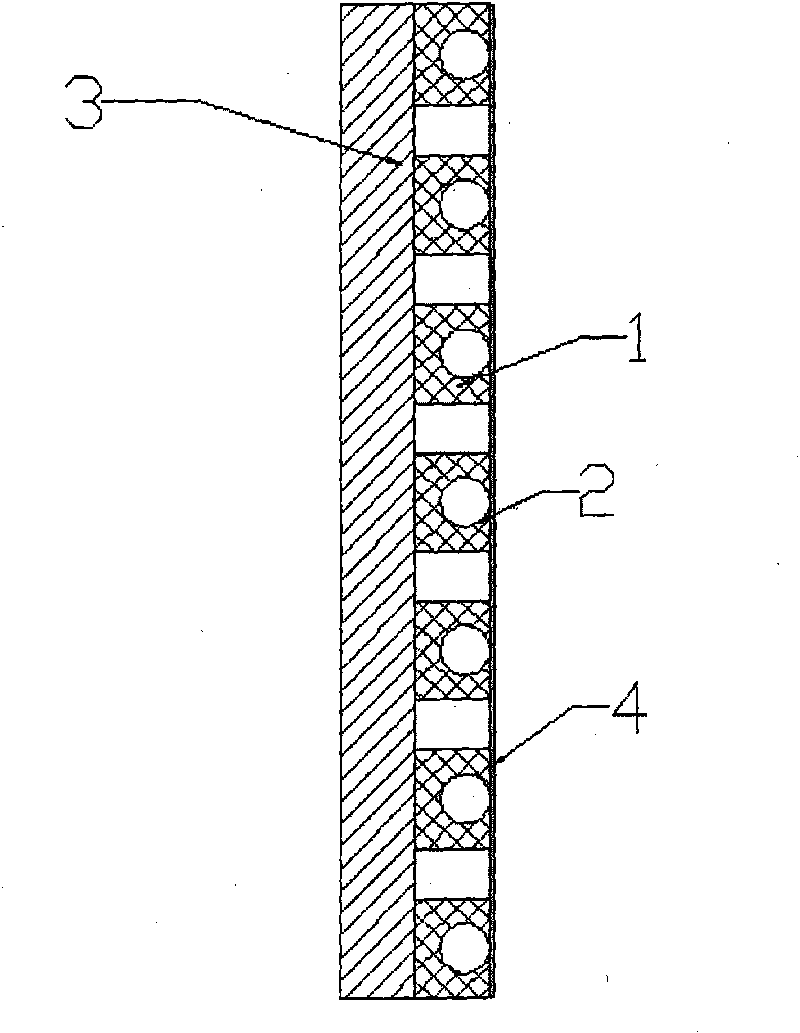

[0028] The thermal storage material in this embodiment is a fixed phase change material, combined with figure 2 illustrate: figure 1 Among them, 1 is a fixed phase change material, 2 is a condensation pipe, 3 is a refrigerator insulation material, and 4 is a refrigerator box wall.

[0029] The difference between this embodiment and Embodiment 1 is that in this embodiment the condensation pipe 2 does not directly contact the refrigerator wall 4 , but in Embodiment 1 the condensation pipe 2 directly contacts the refrigerator wall.

Embodiment 3

[0031] The thermal storage material in this embodiment is a fixed phase change material, combined with image 3 illustrate: figure 1 Among them, 1 is a fixed phase change material, 2 is a condensation pipe, 3 is a refrigerator insulation material, and 4 is a refrigerator box wall.

[0032] The structure of the heat exchanger in this embodiment: the condensation pipe 2 is in direct contact with the refrigerator wall 4, and the shape-setting phase change material 1 is not completely fast, but the condensation pipe 2 is surrounded by the shape-setting phase change material 1, and It is fixed between the refrigerator insulation material 3 and the refrigerator case wall.

[0033] This embodiment mainly considers saving the shape-fixed phase-change material, and only uses the shape-set phase-change material where it is used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com