Sparingly soluble bearing of engine

An engine, slightly soluble technology, used in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of environmental pollution, accidents, and high costs, and achieve the effects of low emissions, elimination of dry friction, and uniform support force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

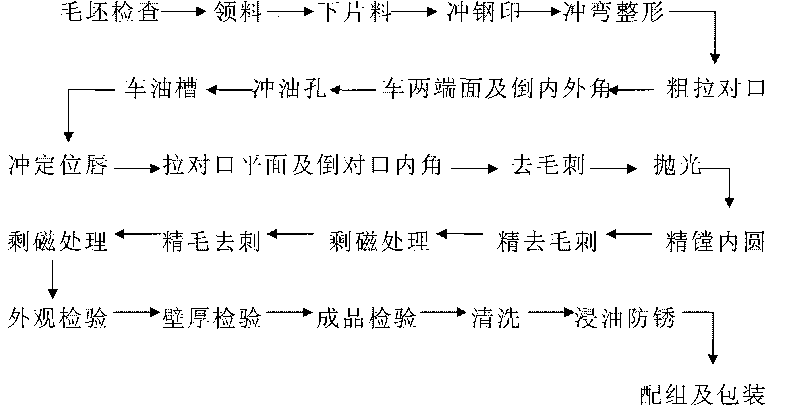

Method used

Image

Examples

Embodiment Construction

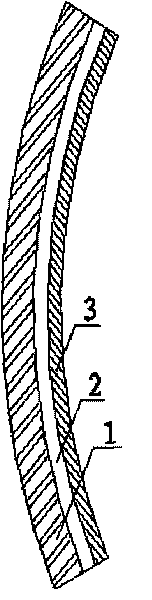

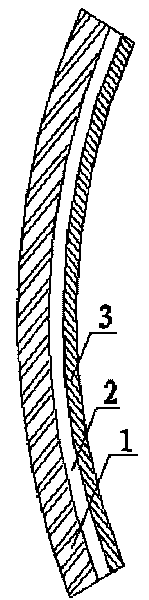

[0020] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a steel back layer 1, a base layer 2 and a slightly soluble layer 3 from outside to inside, wherein the base layer 2 is an aluminum material, and the slightly soluble layer 3 is an environmentally friendly iron-silicon material; the composition of the iron-silicon environmental protection material is : Fe 30-38%, Si 60-68%, Al2-4%; the thickness of the base layer 2 is 0.05-0.15mm, and the thickness of the slightly soluble layer 3 is 0.05-0.90mm; the steel back layer 1, base layer 2 and the slightly soluble layer 3 are adhered together by high temperature sintering.

[0021] When the inner surface of the bearing pad matching the shaft diameter contacts the grease, the iron-silicon environmental protection material can form a slightly soluble layer, absorb the lubricating oil on the sliding surface of the bearing pad, and reliably form an oil film, so that the friction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com