Bi-component room temperature vulcanizing silicone rubber for photovoltaic component

A technology of room temperature vulcanization and photovoltaic modules, applied in the field of silicone rubber, can solve the problems of slow curing speed, affecting efficiency, poor aging resistance, etc., achieve fast curing speed, good bonding performance, and improve high temperature resistance and damp heat aging resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

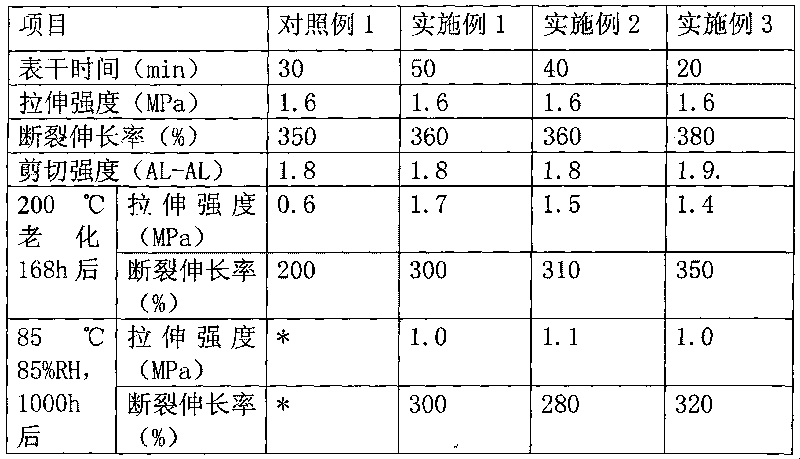

Embodiment 1

[0019] Example 1: A component: Weigh 200g of 20000mPa.s hydroxyl-terminated polydimethylsiloxane, 80g of 1000mPa.s dimethyl silicone oil, 160g of nano-calcium carbonate, 20g of R202 white carbon black, after premixing, Blend 3 times through a three-roll mill;

[0020] Component B: 0.2g of bismuth triheptanoate, 0.2g of bis(acetylacetonate)diisopropoxytitanium, 2g of hydroxyl silicone oil, mixed for 15min under nitrogen protection, added 16g of ethyl orthosilicate, γ-aminopropyltri Ethoxysilane 3g, mixed for 10min under nitrogen protection.

Embodiment 2

[0021] Example 2, component A: Weigh 200g of 20000mPa.s hydroxyl-terminated polydimethylsiloxane, 80g of 1000mPa.s dimethyl silicone oil, 160g of nano-calcium carbonate, and 20g of R202 white carbon black. After premixing, Blend 3 times through a three-roll mill;

[0022] Component B: 2g of bismuth triheptanoate, 1g of bis(acetylacetonate)diisopropoxytitanium, 1g of hydroxyl silicone oil, mixed for 15min under nitrogen protection, added 16g of ethyl orthosilicate, γ-aminopropyltriethoxy base silane 3g, mixed for 10min under nitrogen protection.

Embodiment 3

[0023] Example 3, component A: Weigh 200g of 20000mPa.s hydroxyl-terminated polydimethylsiloxane, 80g of 1000mPa.s dimethyl silicone oil, 160g of nano-calcium carbonate, and 20g of R202 white carbon black. After premixing, Blend 3 times through a three-roll mill;

[0024] Component B: 1 g of bismuth triheptanoate, 0.5 g of bis(acetylacetonate) diisopropoxy titanium, 3 g of hydroxyl silicone oil, mixed for 15 minutes under nitrogen protection, added 16 g of ethyl orthosilicate, γ-aminopropyl triethyl 3 g of oxysilane, mixed for 10 min under nitrogen protection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com