Preparation method of adhesive purpose chloroprene rubber

A neoprene and bonding technology, which is applied in the field of preparation of adhesive neoprene rubber, can solve the problem of unstable solubility of adhesive neoprene rubber, large deviation of Mooney viscosity and other performance indicators, and no re-initiation single problem

- Summary

- Abstract

- Description

- Claims

- Application Information

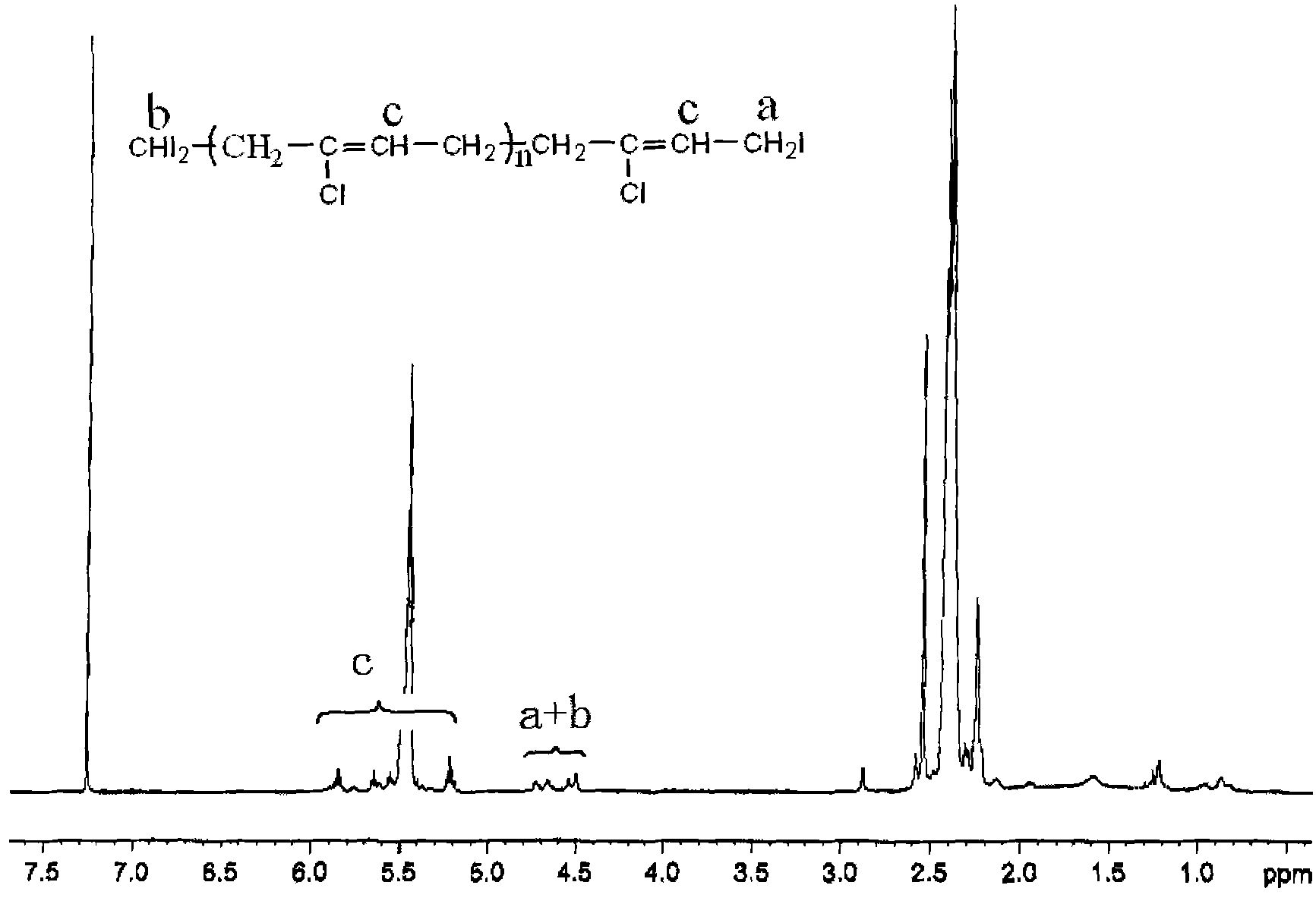

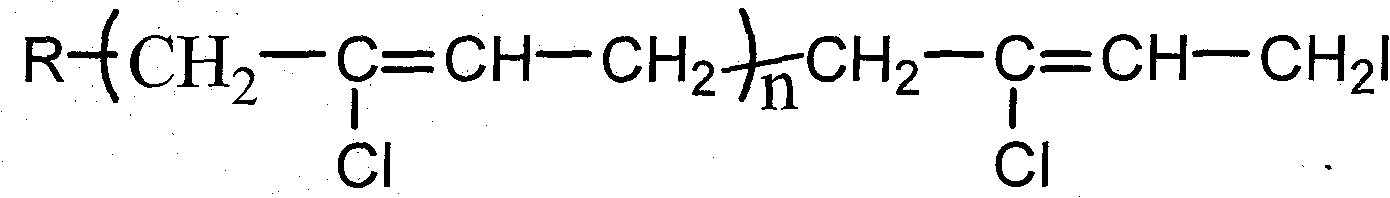

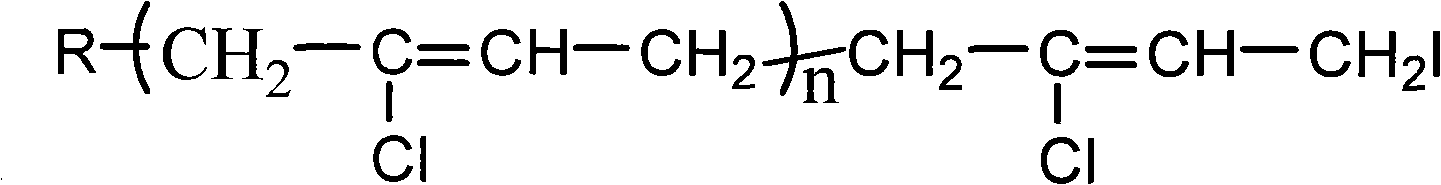

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1.05g of iodoform (accounting for 0.15% of monomer mass) and 25.00g of disproportionated rosin were uniformly dissolved in 700g of chloroprene monomer (CP), and the oil phase preparation temperature was 15°C±2°C. The configured oil phase was added to a 2000ml four-necked bottle, and the water phase (900g water, 1.40g sodium carbonate, 1.40g sodium lauryl sulfate, 0.85gLOMAR PW, 2.50g sodium hydroxide) was added under stirring. Claims no emulsification for 35 minutes at °C. Then cool down, add a redox initiator composed of 1.35g potassium persulfate, 1.85g sodium sulfite and 0.70g sodium formamidine sulfinate, and carry out polymerization reaction at 5°C-10°C. When the chloroprene conversion rate reaches 91%, add the terminator phenothiazine once under stirring, stir for 20 minutes to terminate the polymerization reaction, then adjust the pH value to 5-6 with acetic acid, and then use 3 liters of saturated CaCl 2 Solution gel, after washing with water on the rubber mixe...

Embodiment 2

[0029] 1.44g of iodoform (accounting for 0.205% of monomer mass) and 22.50g of disproportionated rosin were uniformly dissolved in 700g of chloroprene monomer (CP), and the oil phase preparation temperature was 15°C±2°C. The configured oil phase was added to a 2000ml four-necked bottle, and the water phase (900g water, 1.40g sodium carbonate, 1.40g sodium lauryl sulfate, 1.85g LOMAR PW, 3.05g sodium hydroxide) was added under stirring. Emulsify at ℃ for 35 minutes. Then cool down, add a redox initiator composed of 1.80g potassium persulfate, 2.10g sodium sulfite and 1.50g sodium formamidine sulfinate, and carry out polymerization reaction at 5°C-10°C. When the conversion rate of chloroprene reaches 94%, add the terminator phenothiazine once under stirring, stir for 20 minutes to terminate the polymerization reaction, then adjust the pH value to 5-6 with acetic acid, and then use 3 liters of saturated CaCl 2 The solution gel was washed with water on the rubber mixer and dried ...

Embodiment 3

[0031] 1.54g of iodoform (accounting for 0.22% of monomer mass) and 25.00g of disproportionated rosin were uniformly dissolved in 700g of chloroprene monomer (CP), and the oil phase preparation temperature was 15°C±2°C. Add the configured oil phase into a 2000ml four-necked bottle, add the water phase (900g water, 1.40g sodium carbonate, 1.40g sodium lauryl sulfate, 0.85gLOMAR PW, 2.50g sodium hydroxide) under stirring, Emulsify at ℃ for 25 minutes. Then cool down, add a redox initiator composed of 1.35g potassium persulfate, 1.85g sodium sulfite and 0.70g sodium formamidine sulfinate, and carry out polymerization reaction at 5°C-10°C. When the chloroprene conversion rate reaches 93%, add the terminator phenothiazine once under stirring, stir for 25 minutes to terminate the polymerization reaction, then use 3 acetic acid to adjust the pH value to 5-6, and then use 3 liters of saturated CaCl 2 The solution gel was washed with water on the rubber mixer and dried to obtain adhes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com