Method for monitoring tire burst or severe air leakage of vehicle

A puncture and violent technology, used in tire measurement, vehicle parts, tire parts, etc., can solve problems such as low accuracy, low cost, and easy false alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

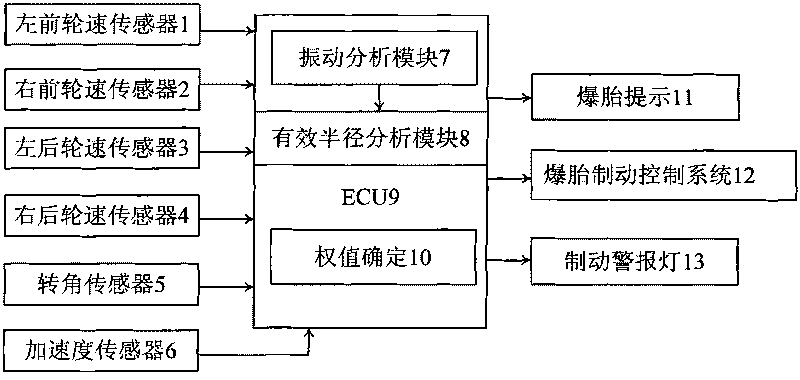

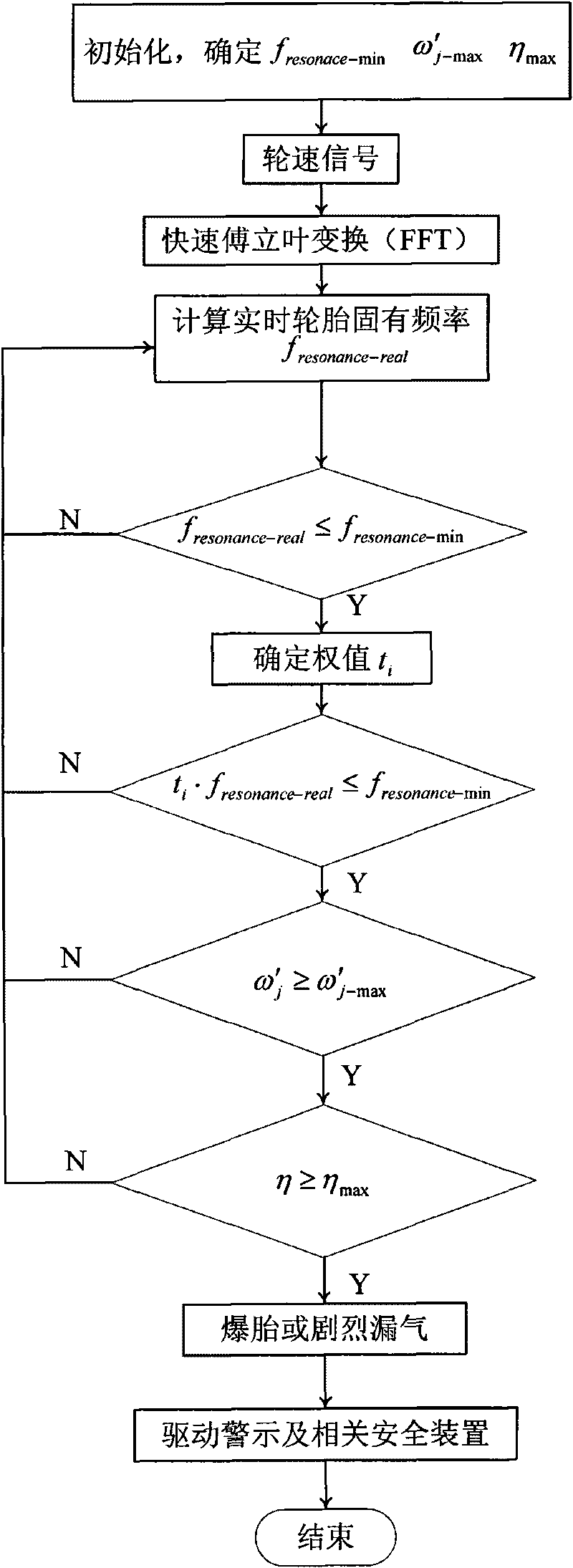

[0018] The method for monitoring a vehicle tire blowout or severe air leakage utilizes the characteristics of a sharp decrease in the natural frequency of a tire blowout or severe air leakage and a sharp decrease in the effective radius of the tire, by analyzing the vibration characteristics of each wheel speed signal and Effective radius characteristic analysis, obtain the natural frequency characteristics and effective radius characteristics of each tire of the vehicle, and determine the threshold (criterion) of tire blowout or severe air leakage related characteristics on the basis of empirical formulas and experiments If the tire is within the range of the air criterion, then according to the current turning and braking conditions of the vehicle, the weighted judgment of the tire blowout or severe air leakage will be carried out to determine whether ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com