Tooth shape processing and molding method of hollow pipe fitting and special mold thereof

A technology for processing and forming hollow tubes, which is applied to forming tools, other household appliances, household appliances, etc., can solve the problems of high cost, affecting the rigidity of parts, perforation of pipe fittings, etc., and achieves the effect of simple method and guaranteed rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

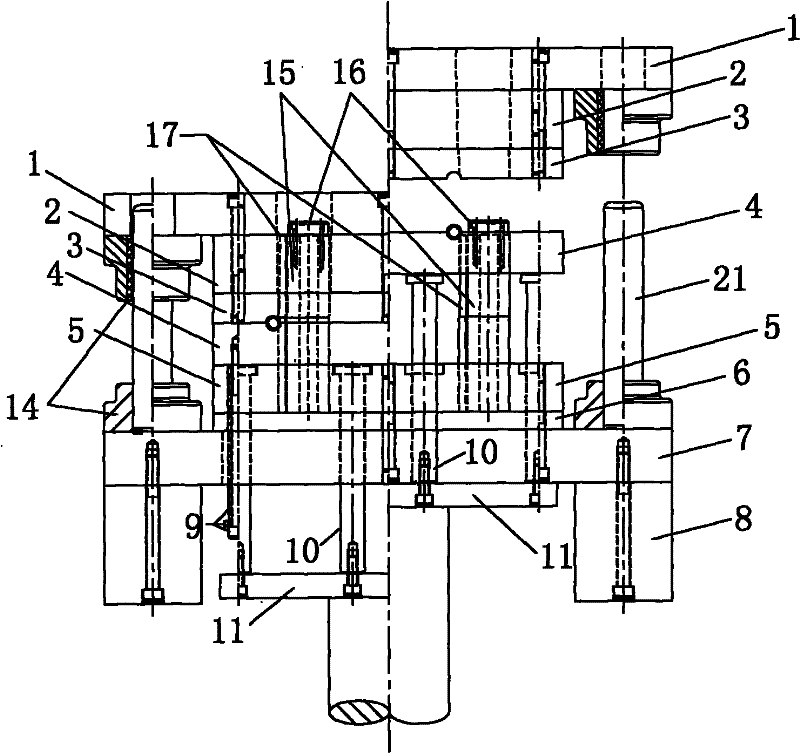

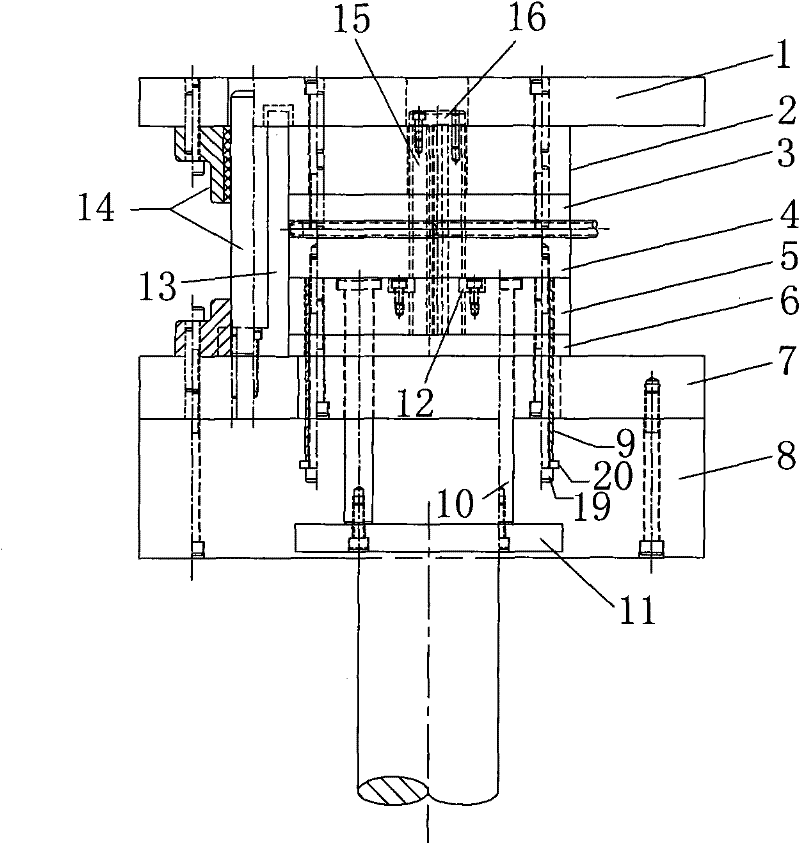

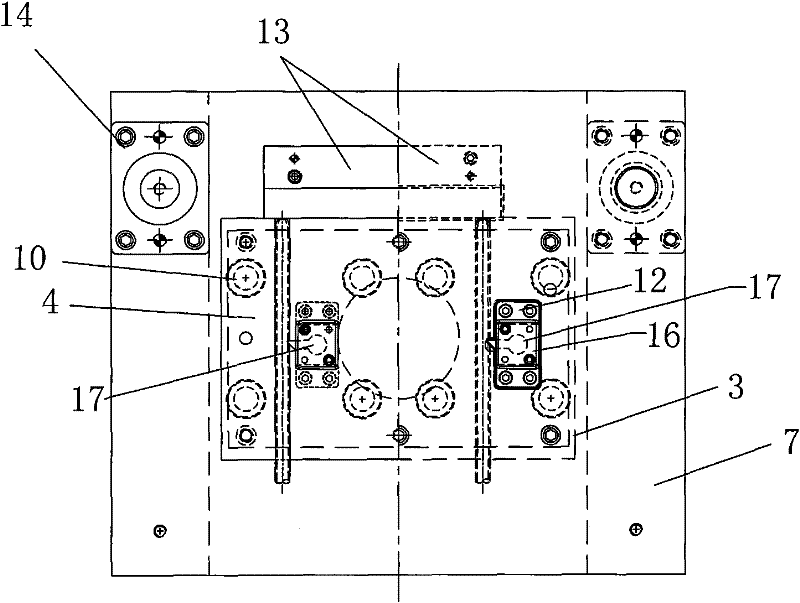

[0012] See figure 1 , the tooth shape processing and forming method of the hollow pipe fitting of the present invention, the pipe fitting to be processed is clamped by the upper clamping plate 3 and the lower clamping plate 4, and the forming punch 17 is downward along the tangential direction of the pipe wall of the tooth profile processing part of the pipe fitting to be processed sports. The forming surface of the forming punch is a slope; the slope of the slope is not more than 1.5 degrees; the material of the pipe fitting to be processed is a high-frequency welded pipe; when the tooth width of the pipe fitting to be processed is greater than 5mm, the tooth depth is greater than 1.8mm or the wall thickness of the pipe fitting is greater than 1.8mm First, cut off 20% to 30% of the wall thickness of the pipe material, and then use the forming punch 4 to punch down along the tangential direction of the pipe wall.

[0013] The special mold for the tooth shape processing and fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com