Biomimetic photocatalysis membrane separation assembly for purifying water

A photocatalytic membrane and separation component technology, applied in semi-permeable membrane separation, membrane technology, chemical instruments and methods, etc., to reduce the phenomenon of concentration polarization, flexible structure, and uniform light reception.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

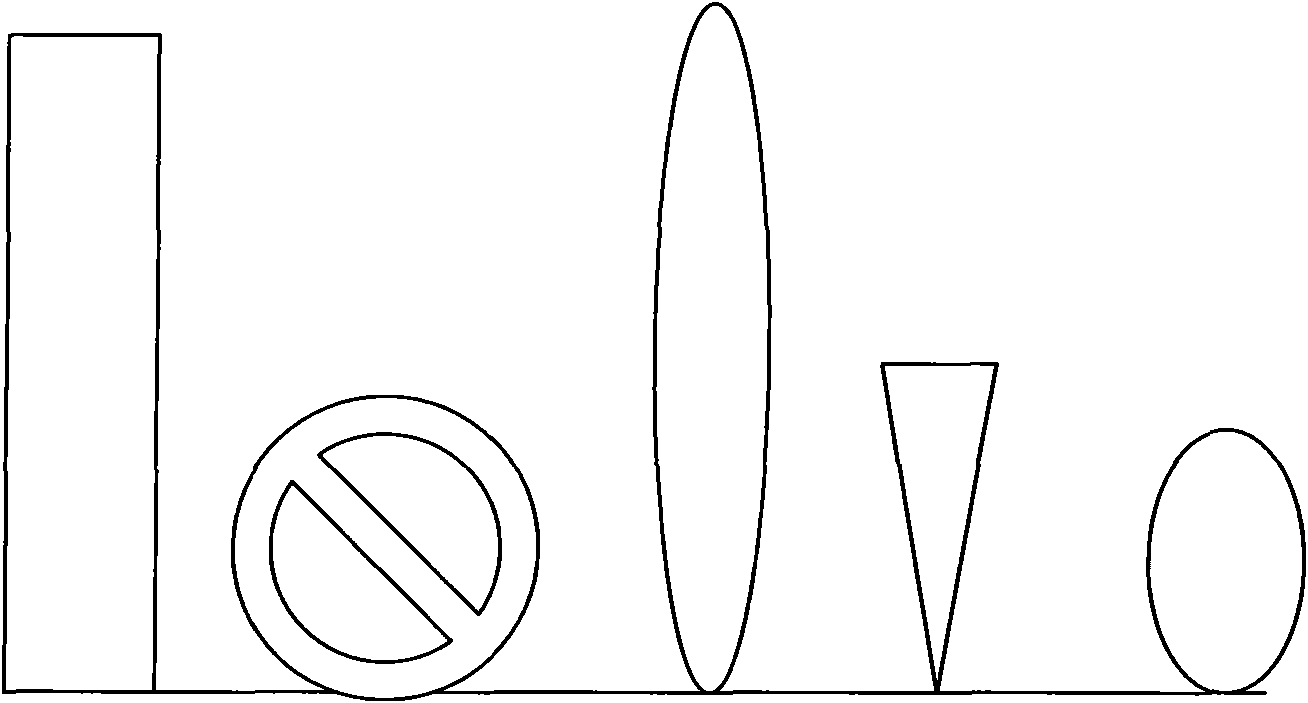

[0025] The metal fine mesh membrane material or organic membrane separation membrane material is made into the shape of primary leaves such as slender strip leaves, lotus leaf leaves, flower-like leaves, etc., and the plastic support structure skeleton is wrapped inside, and the upper and lower sides of the membrane are wrapped. Seal, leave the position of the outlet pipe, and connect with the outlet pipe to form a secondary diaphragm structure.

[0026] Put the outlet pipes of several secondary diaphragms into a large water pipe that can be called a branch pipe, and seal the surroundings to form a three-stage membrane module structure; put the outlet pipes of the three-stage membrane modules into a larger The so-called photocatalyst is pre-loaded on the membrane, or loaded after assembly and overactivated.

[0027] In this way, the membrane assembly of the photocatalytic separation membrane with the bionic plant structure is obtained.

[0028]Connect the outlet pipes of seve...

Embodiment 2

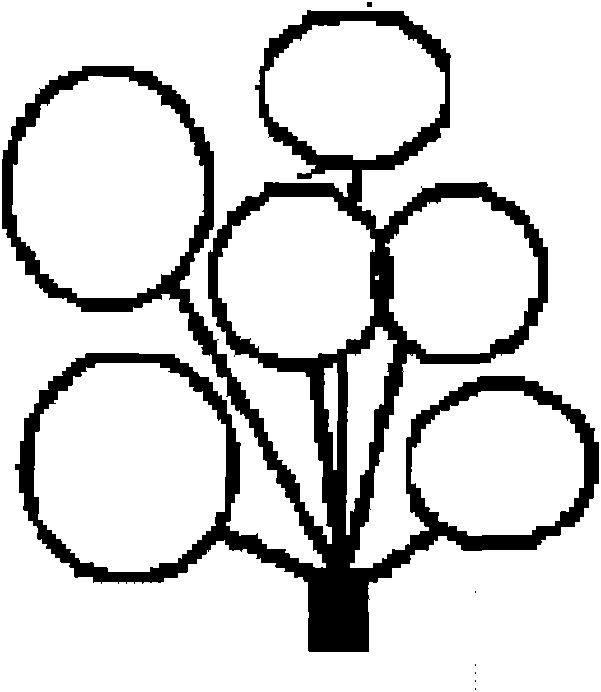

[0030] Biomimetic Catalytic Separation Membrane Module

[0031] Using polyester filter cloth as the base membrane, a bionic membrane is made. The surface coating with photocatalytic activity was prepared by sol-gel and PVA cross-linking heat treatment technology. Wrap the supporting frame inside with two pieces of film, and press and seal the four sides like a blade, leaving one separated fluid outlet pipe. Afterwards, a plurality of the secondary membranes are assembled into a three-stage catalytic separation membrane assembly imitating the shape of a plant. The catalyst is composed of titanium dioxide doped series, etc., through various mechanisms such as ultraviolet / visible light catalysis, hydrogen peroxide (dye phthalocyanine) sensitized photocatalysis, etc. The conditions for preparing the catalyst coating on the surface of the membrane can control the thickness and weight gain of the final composite membrane coating. The weight gain range of the membrane is 1-20%. ho...

Embodiment 3

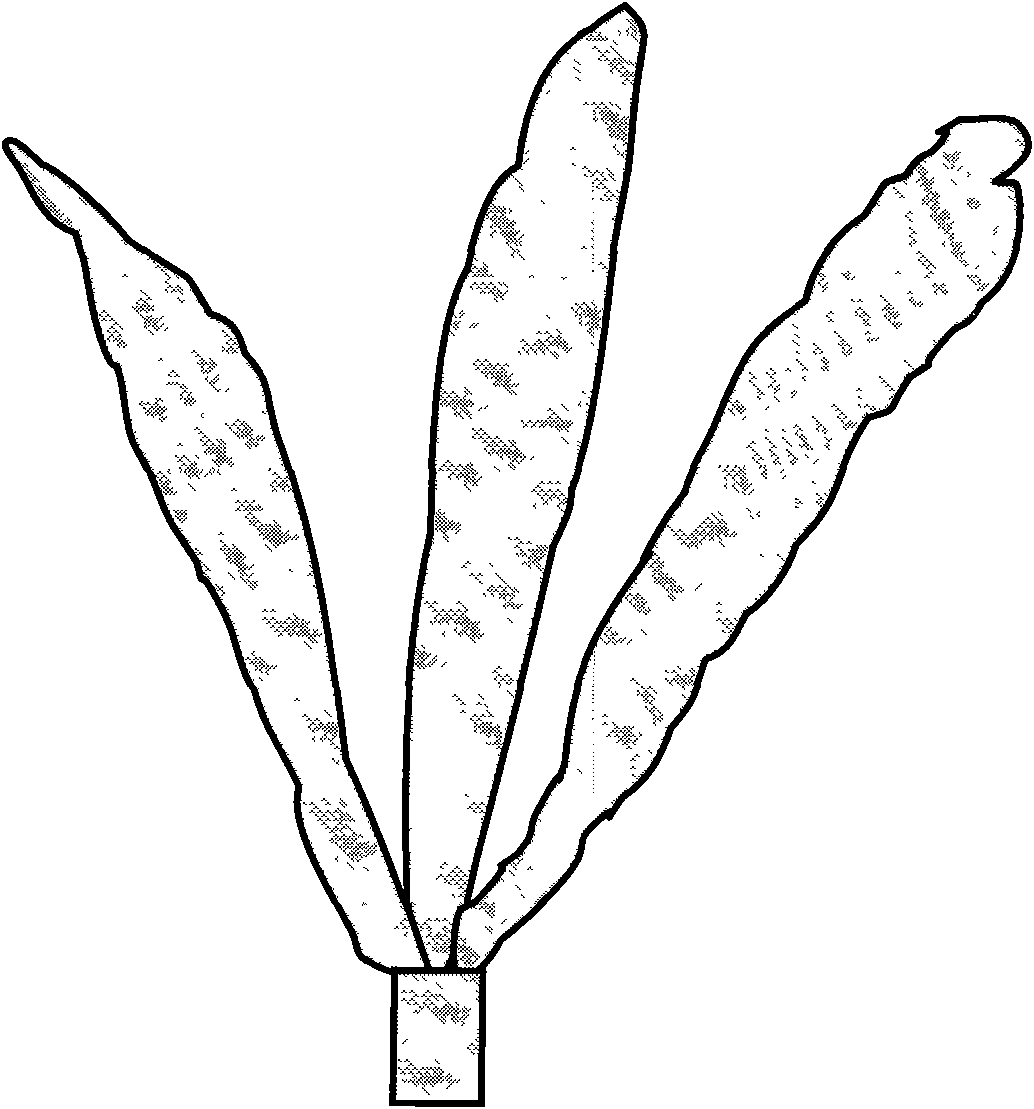

[0034] Cascade biomimetic photocatalytic separation membrane module water purification system

[0035] The above-mentioned secondary structure of bionic photocatalytic membranes with different numbers and shapes, the tertiary membrane module structure similar to branches, and the photocatalytic membrane separation module of quaternary structure imitating plants and trees.

[0036] Put several or more four-stage biomimetic photocatalytic separation membrane modules of different heights in the pool, the upper end is submerged underwater, and the outlet pipes at the lower end are connected to each other to form an outlet pipe network, which is collected into the main outlet pipe. Illumination and photocatalysis When irradiated with 254nm ultraviolet germicidal light and the average light intensity of leaves can reach 366 microwatts / square centimeter, when 1000ml aqueous solution containing 10mg / g2,4 dichlorophenol passes through for 2 hours, the total area is 300cm2, containing T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com