Method for analyzing oil mass fraction of drilling well fluid by nuclear magnetic resonance

A technology of mass fraction and nuclear magnetic resonance, which is applied in the field of oily analysis of drilling fluid in petroleum drilling, can solve the problems of large randomness of oil concentration in drilling fluid, large error of detection results, and unrepresentative, etc., and achieve authentic results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

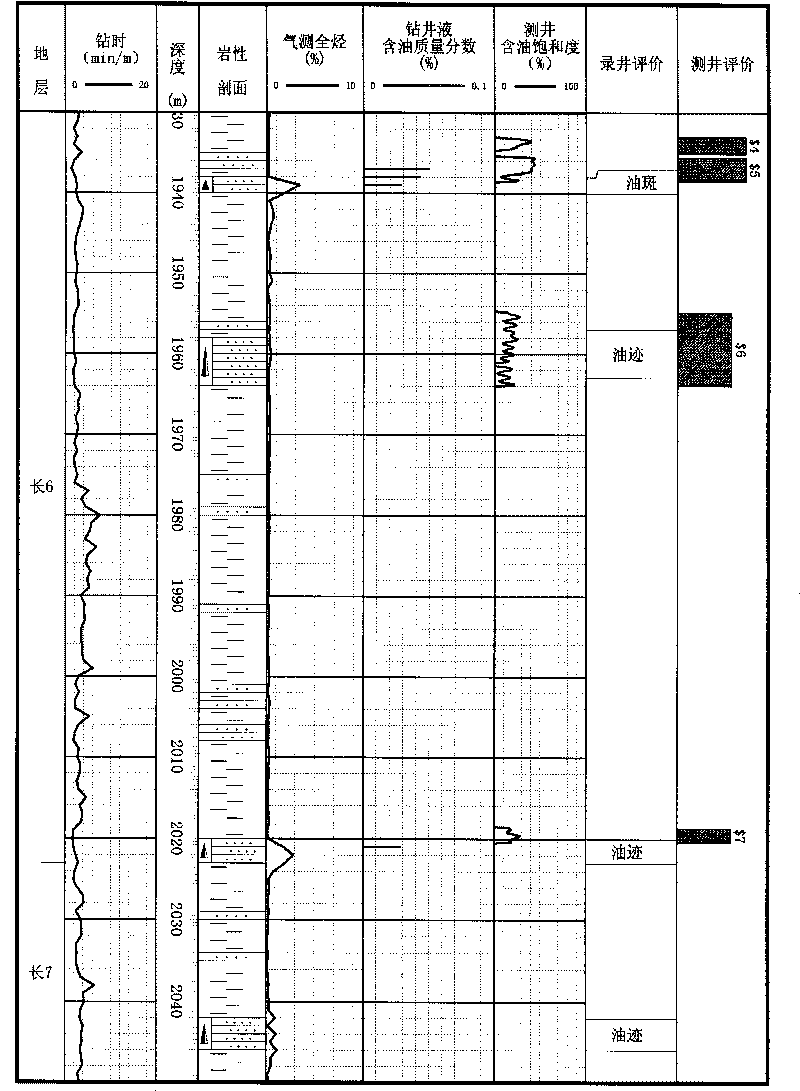

[0031] Example 1: NMR analysis while drilling of well HH266 in the Yanchang Formation of the Triassic in the southern Ordos Basin

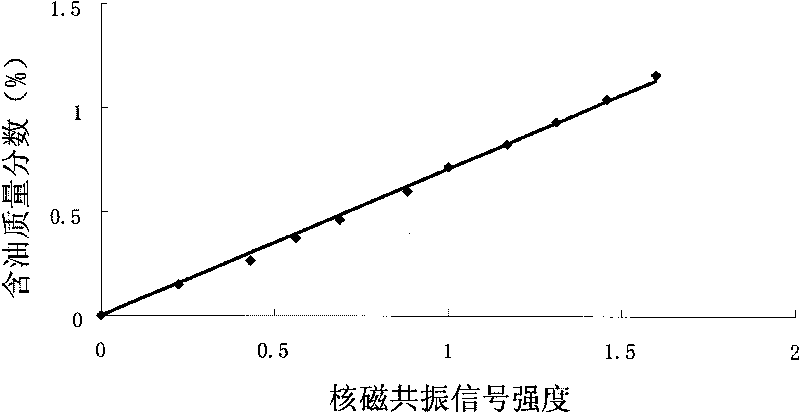

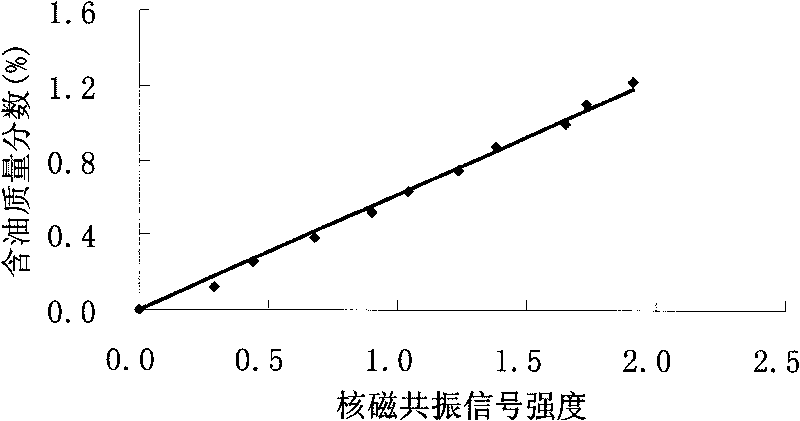

[0032] The present invention utilizes nuclear magnetic resonance technology to analyze the method for oily mass fraction of drilling fluid, including nuclear magnetic resonance analysis instrument calibration, drilling fluid oily mass fraction work curve making Establishment of drilling fluid oil mass fraction working curves for two layers), drilling fluid sample collection, processing and NMR analysis, and calculation of drilling fluid oil mass fraction parameters. Specific steps are as follows:

[0033] (1) Debugging and calibration of NMR analysis instruments

[0034] 1. The analysis instrument is UNIQ PMR pulse nuclear magnetic resonance analyzer, version 3.0 software. This instrument is one of the most advanced nuclear magnetic resonance analysis instruments used in the petroleum field in China. The instrument is stable, the calibration li...

example 2

[0081] Example 2: NMR analysis while drilling of well HH26-7 in the Yanchang Formation of the Triassic in the southern Ordos Basin

[0082] The same method as Example 1 was used to carry out NMR logging while drilling in well HH26-7.

[0083] Table 4 is the analysis data table of oily mass fraction of drilling fluid by NMR. The "sample depth" in the table is the depth of the drilling fluid collected while drilling, which is late to the well depth; "Oil content mass fraction (%)" is the data of oil content mass fraction of drilling fluid calculated according to the corresponding formation formula.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com