Dipped paper mould pressing wood flooring block

A technology of floor boards and impregnated paper, which is applied in the field of wooden floors, can solve problems such as stress concentration, achieve the effects of reducing stress concentration, reducing seepage pressure, and increasing the modulus of bending section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further describe the present invention in detail with embodiment below:

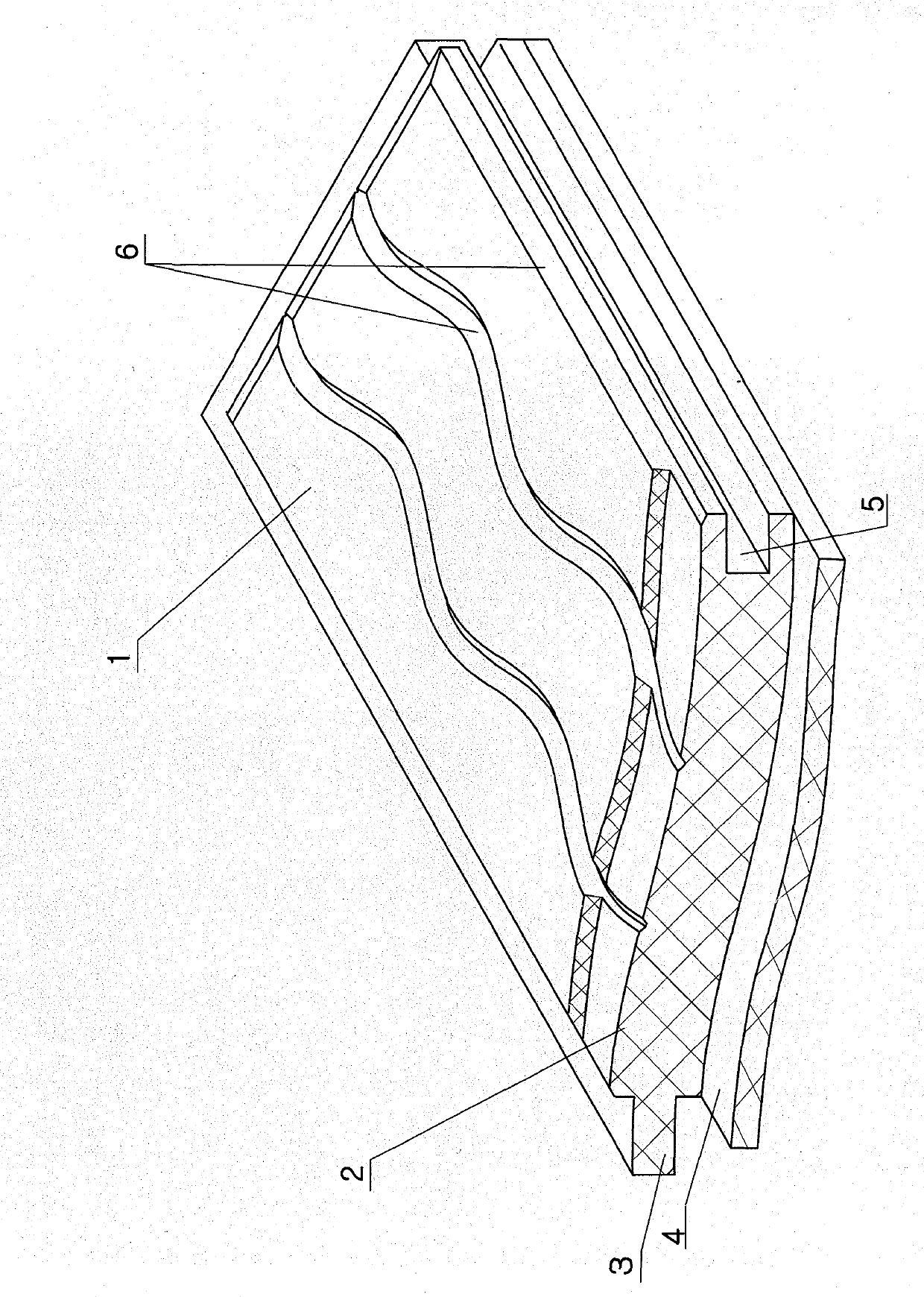

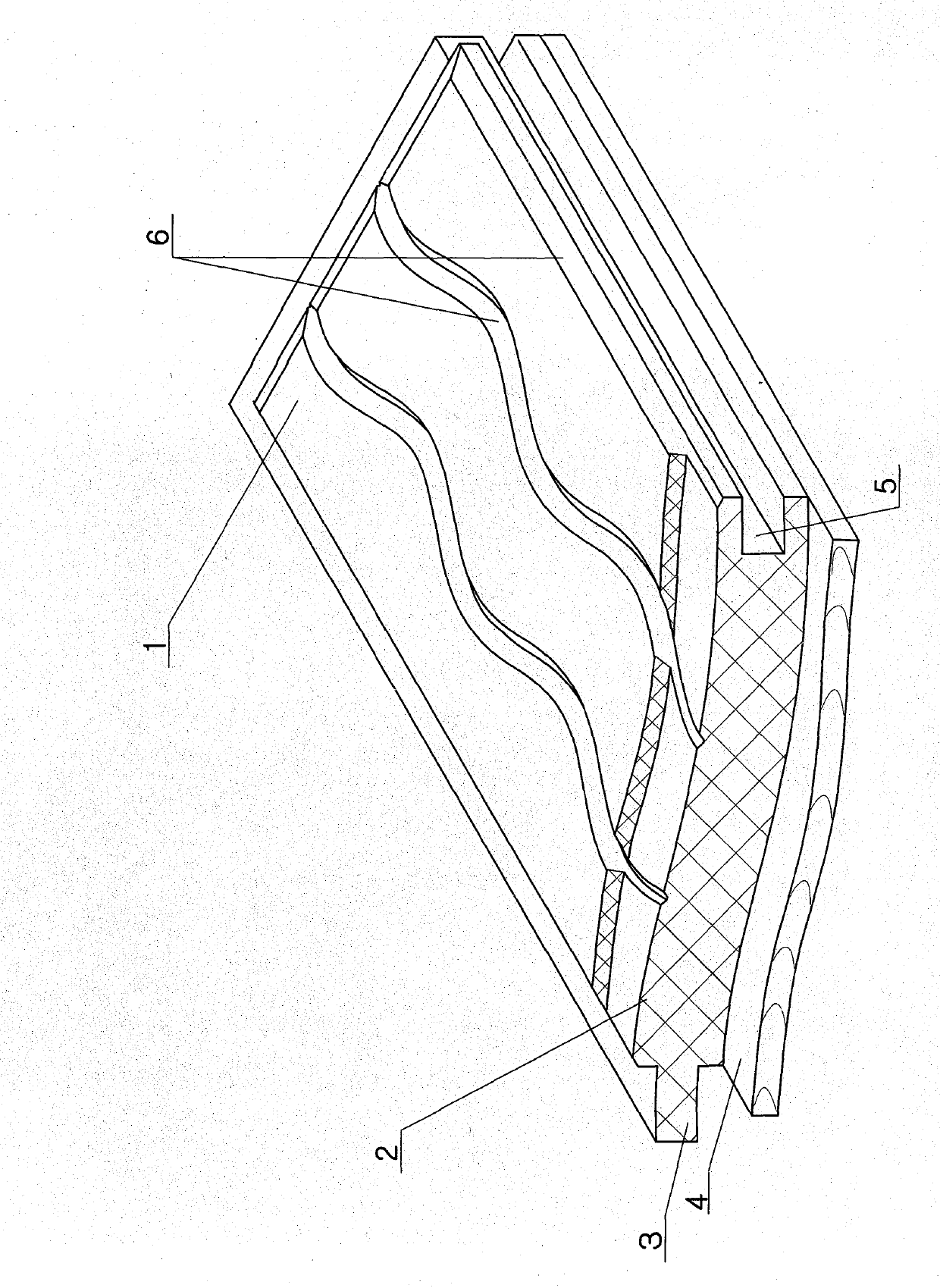

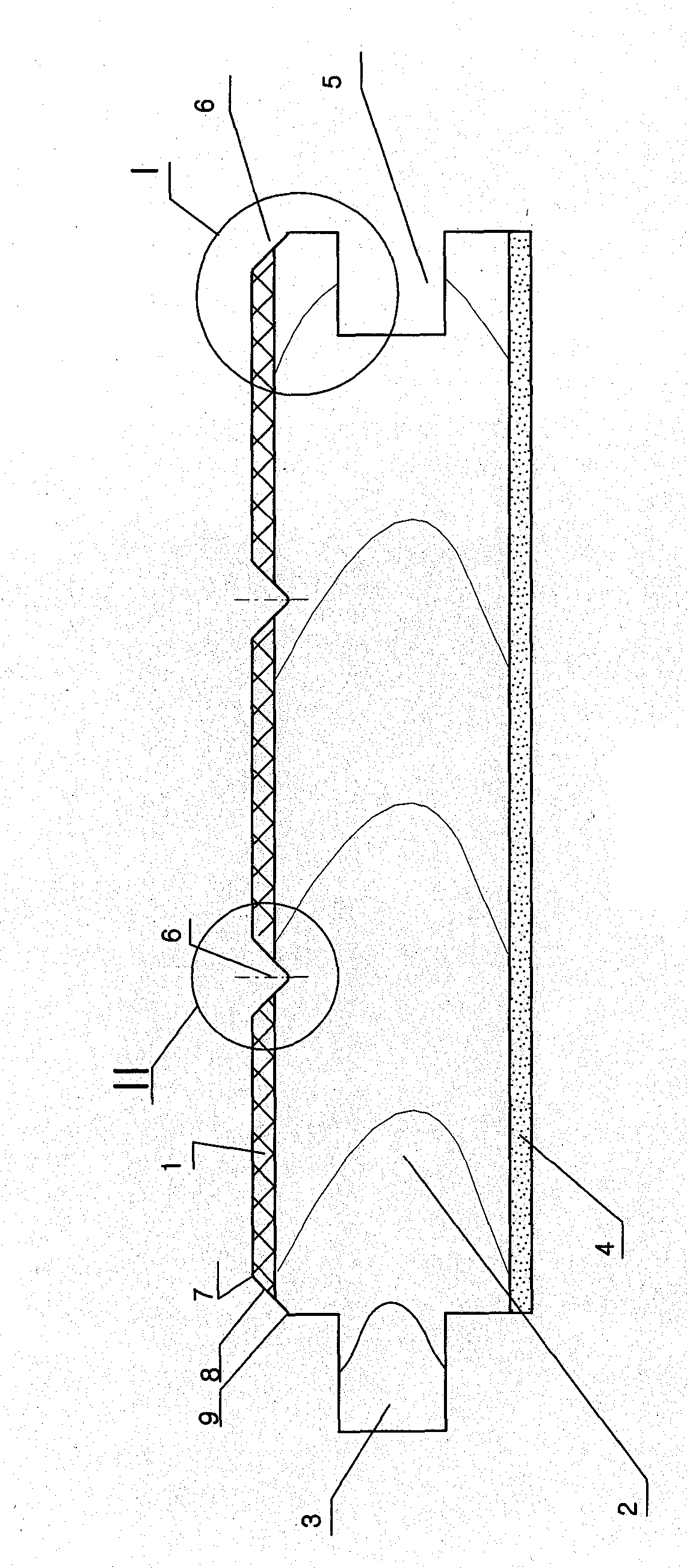

[0024] refer to figure 1 , 3 , 4 and 5, embodiment 1 comprises surface layer structure 1, base material 2 and bottom layer 4, surface layer structure 1 comprises wear-resistant layer, surface layer and decoration layer, bottom layer 4 is the decorated cardboard impregnated with thermosetting melamine, and base material 2 is high-density fiberboard , the substrate 2 has matching tenons 3 and grooves 5 at the edges of the four opposite sides, and the surface structure 1 and the substrate 2 overlap a central area under the area of the running surface. The superimposed surface structure 1 and base material 2 in the central area are pressed with indented strips 6 with a combined cross-sectional profile of circular arc segments perpendicular to the bottom surface of the floor board. refer to Figure 9 and 10 , the four sides of the edge area where the surface layer structure 1 and the base materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com