A method for manufacturing mold and a method for manufacturing anti-dazzle membrane

A manufacturing method and a technology of molds, which are applied to the photoplate-making process of pattern surfaces, household appliances, and other household appliances, etc., can solve problems such as flickering, difficulty in precisely controlling concave-convex shapes, and overall whitening of the display surface, so as to prevent flickering Occurrence, good reproducibility, effect of suppressing cloudiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1

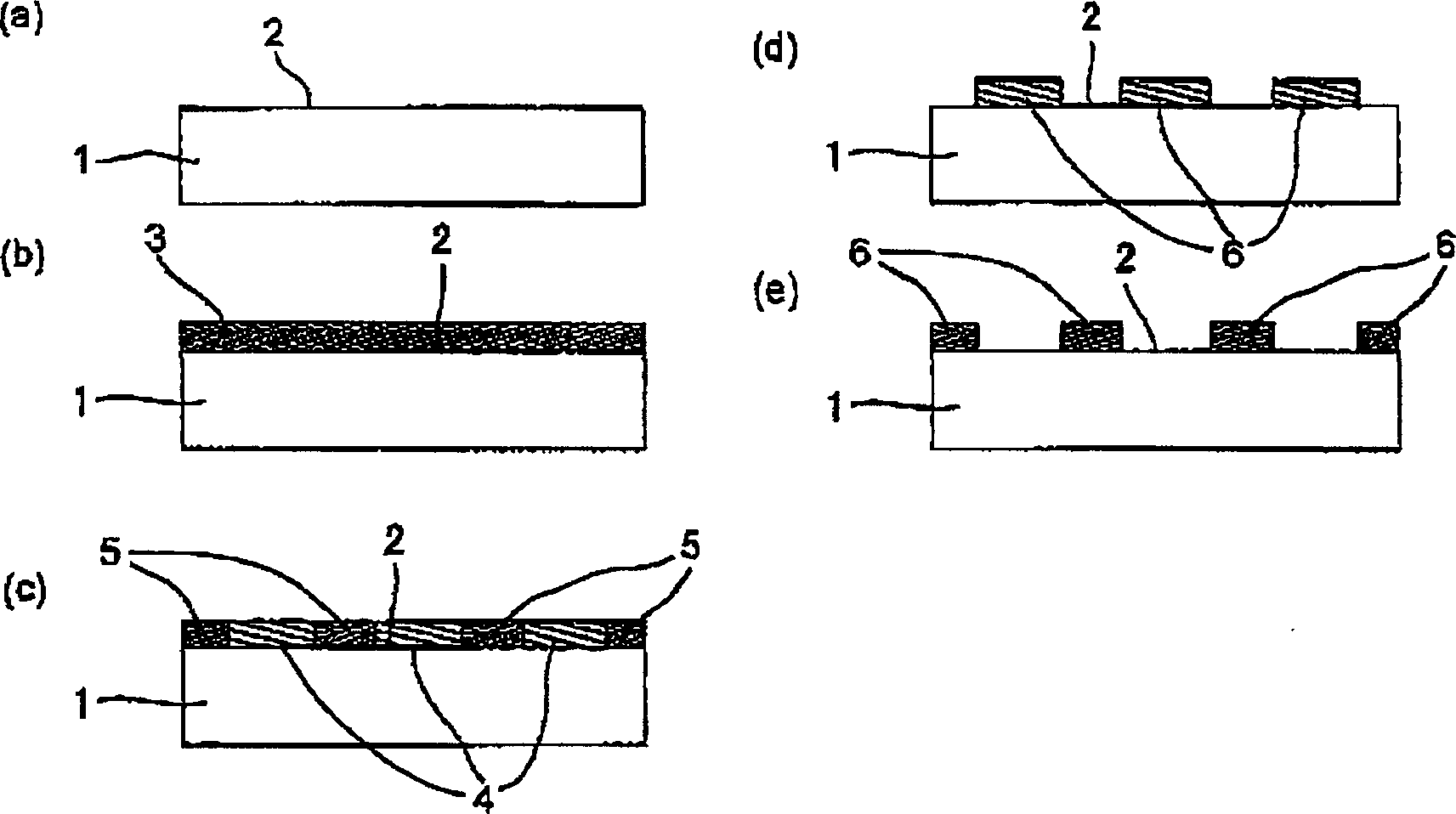

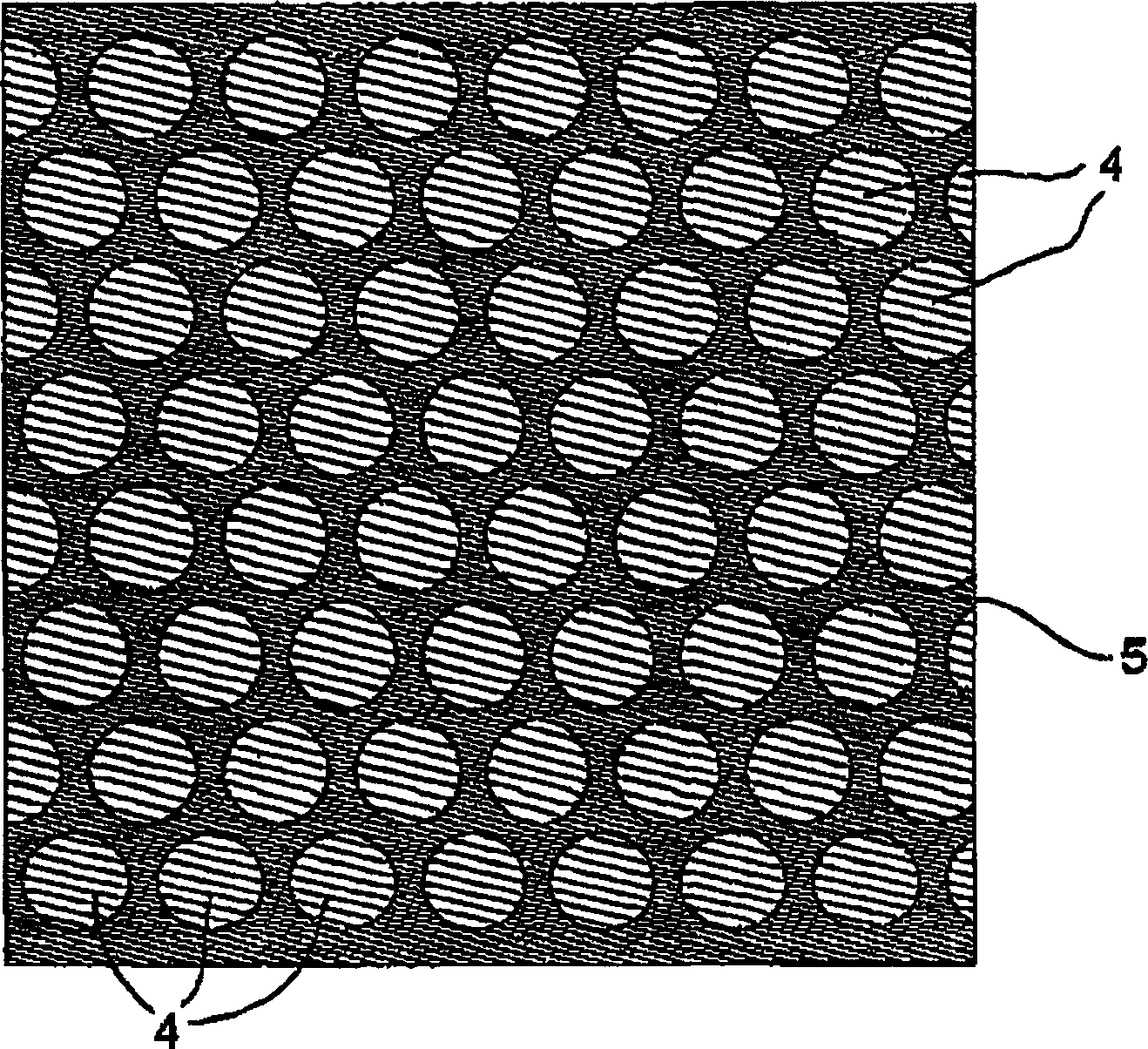

[0130] An object in which Ballard plate copper plating was performed on the surface of an aluminum roll (A5056 according to JIS) having a diameter of 200 mm was prepared. Ballard plate-making copper plating is composed of copper plating layer / thin silver plating layer / surface copper plating layer, and the thickness of the entire plating layer is set to about 200 μm. This copper-plating surface is mirror-polished, the photosensitive resin is apply|coated to the grind|polished copper-plating surface, it dries, and a photosensitive resin film is formed. Next, use a laser to juxtapose the repetitions Figure 11 The pattern of the pattern shown by (a) is exposed to the photosensitive resin film, and it develops. Exposure and development with laser light were performed using Laser Stream FX (manufactured by Think Laboratory Co., Ltd.). The photosensitive resin film uses a positive-type photosensitive resin. Figure 11 In the pattern exposure shown in (a), the ratio of the project...

Embodiment A2

[0137] The photocurable resin composition GRANDIC 806T (manufactured by Dainippon Ink Chemical Industry Co., Ltd.) was dissolved in ethyl acetate to prepare a solution with a concentration of 50% by weight, and 5 parts by weight were added to 100 parts by weight of the curable resin component. A coating liquid was prepared using luciferin TPO (manufactured by BASF, chemical name: 2,4,6-trimethylbenzoyldiphenylphosphine oxide) as a photopolymerization initiator. The coating liquid was applied on a triacetyl cellulose (TAC) film having a thickness of 80 μm so that the coating thickness after drying was 10 μm, and was dried in a dryer set at 60° C. for 3 minutes. The film after drying was press-bonded with a rubber roll on the uneven surface of the mold obtained in Example A1 so that the photocurable resin composition layer was on the mold side, and the film was brought into close contact. In this state, from the TAC film side, the amount of light in terms of h-line is 200 mJ / cm ...

Embodiment B1

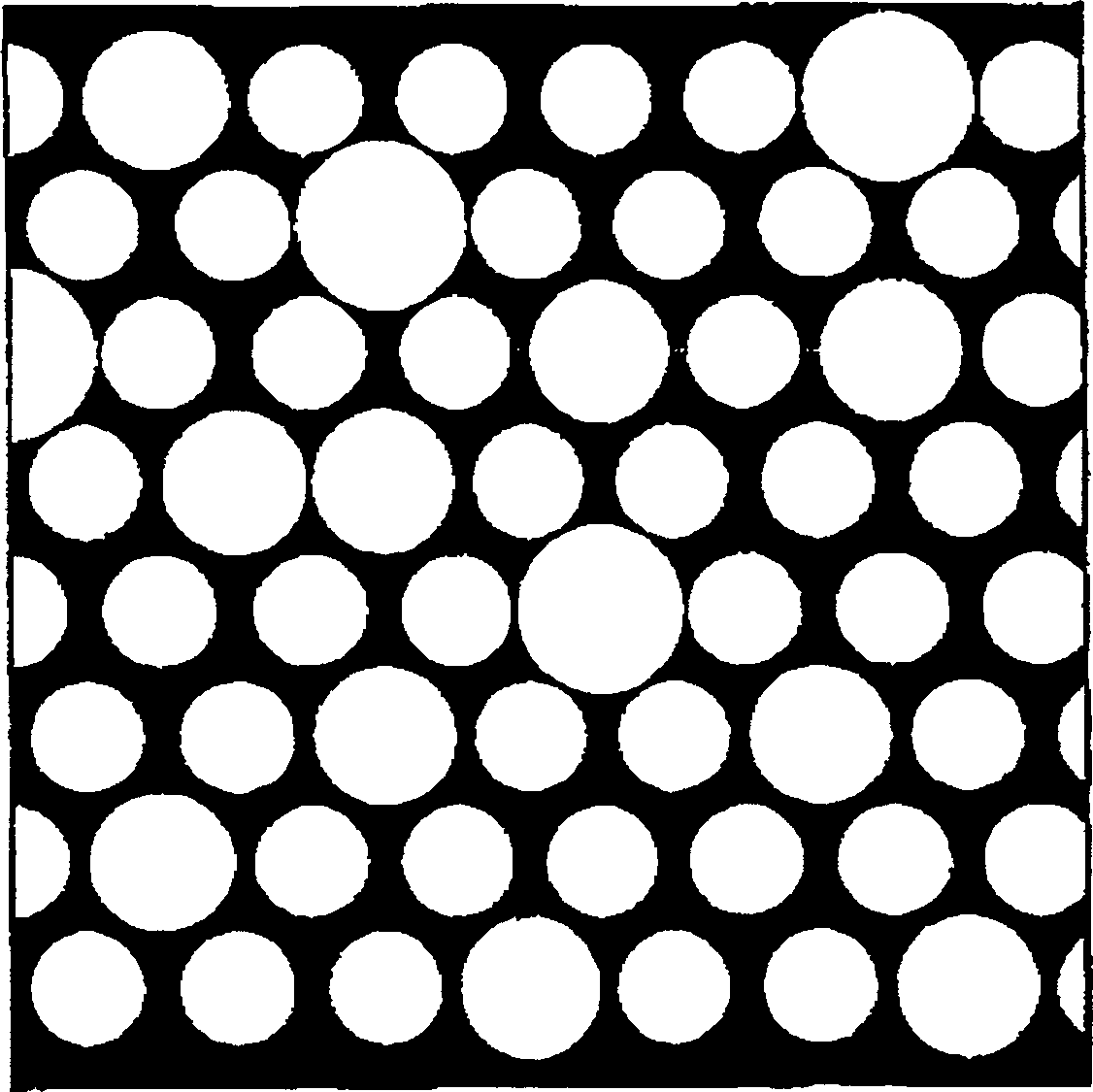

[0172] An object in which Ballard plate copper plating was performed on the surface of an aluminum roll (A5056 according to JIS) having a diameter of 200 mm was prepared. Ballard plate-making copper plating is composed of copper plating layer / thin silver plating layer / surface copper plating layer, and the thickness of the entire plating layer is set to about 200 μm. This copper-plating surface is mirror-polished, the photosensitive resin is apply|coated to the grind|polished copper-plating surface, it dries, and a photosensitive resin film is formed. Next, use a laser to juxtapose the repetitions Figure 16 The pattern which the shown pattern consists of is exposed to the photosensitive resin film, and it develops. Exposure and development with laser light were performed using LaserStream FX (manufactured by Think Laboratory Co., Ltd.). The photosensitive resin film uses a positive-type photosensitive resin. Figure 16 In the pattern exposure shown, the ratio of the project...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com