Screw type pipe pushing and bending machine

A pipe bender and lead screw technology, which is applied in the field of presses, can solve the problems of increased machine cost, large machine cylinder bore, and high energy consumption, and achieve the effect of reducing demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

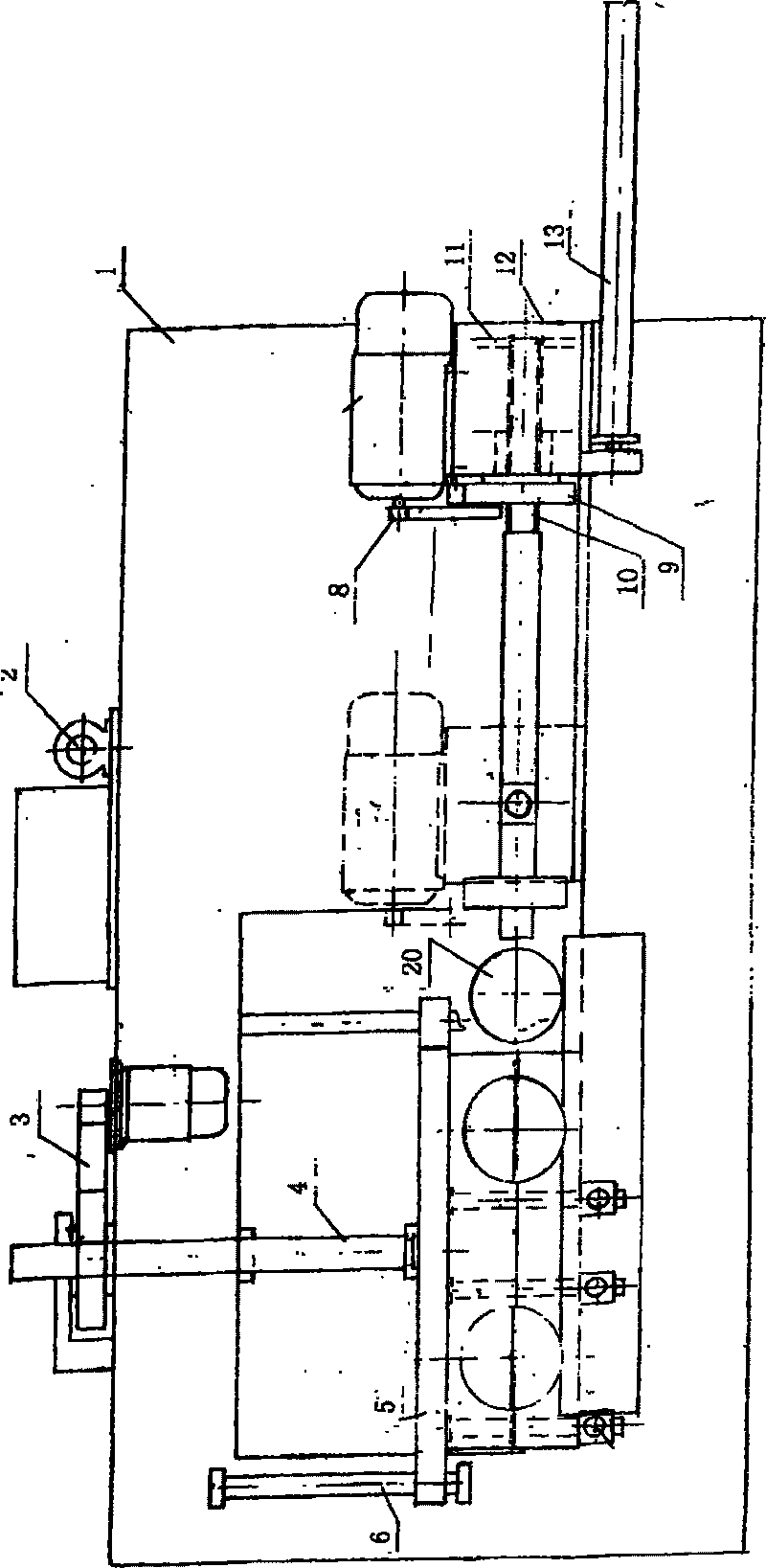

[0021] In conjunction with accompanying drawing, the embodiment of the present invention is described in further detail:

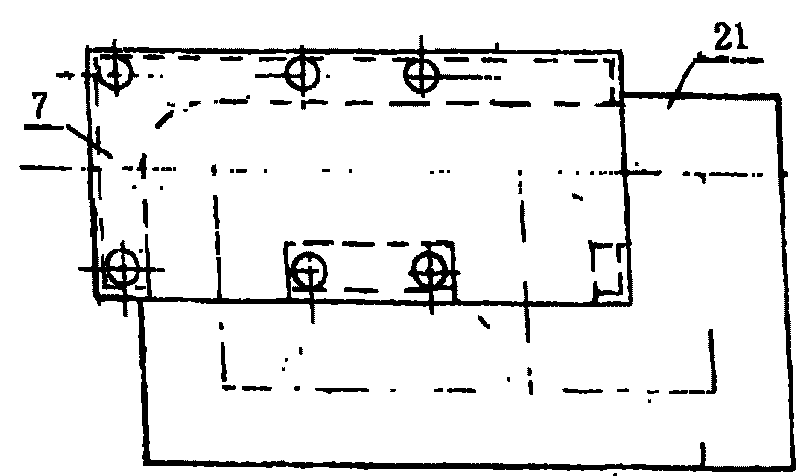

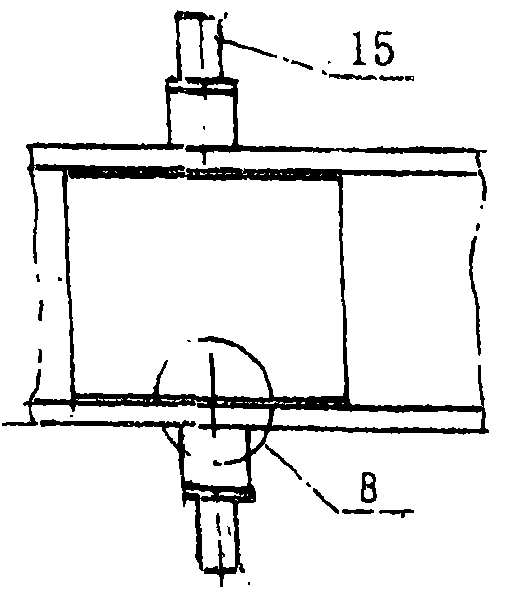

[0022] The screw-type push tube bending machine is mainly composed of: frame 1, pump motor unit and oil tank 2, motor and multi-strand V-belt 3 to drive the screw nut to make the vertical screw 4 move up and down, press platen 5, two groups of symmetry Type guide column 6, mold 7, horizontal output motor and reduction gear group 8, drive the integral gear screw nut 9, make the horizontal screw 10 move horizontally, the tail of the horizontal screw 10 and the machine head 12 are provided to prevent the screw from rotating The square plate 11, the fast oil cylinder 13 drives the machine head 12 to move quickly horizontally, when the fast oil cylinder 13 drives the machine head 12 to move horizontally and quickly to the front position, two symmetrical wedge keys 14 lock the machine head 12, and the two symmetrical wedge keys 14 Pushed and moved by two positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com