Rubber injection machine balance injection structure

An injection machine and balancing technology, which is applied to the field of balanced injection structure of rubber injection machines, can solve the problems of inconvenient control of rubber material temperature, easy vulcanization of rubber material at the nozzle mouth, large pressure loss of rubber material, etc. The effect of reducing the vulcanization amount of the rubber compound and having a simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

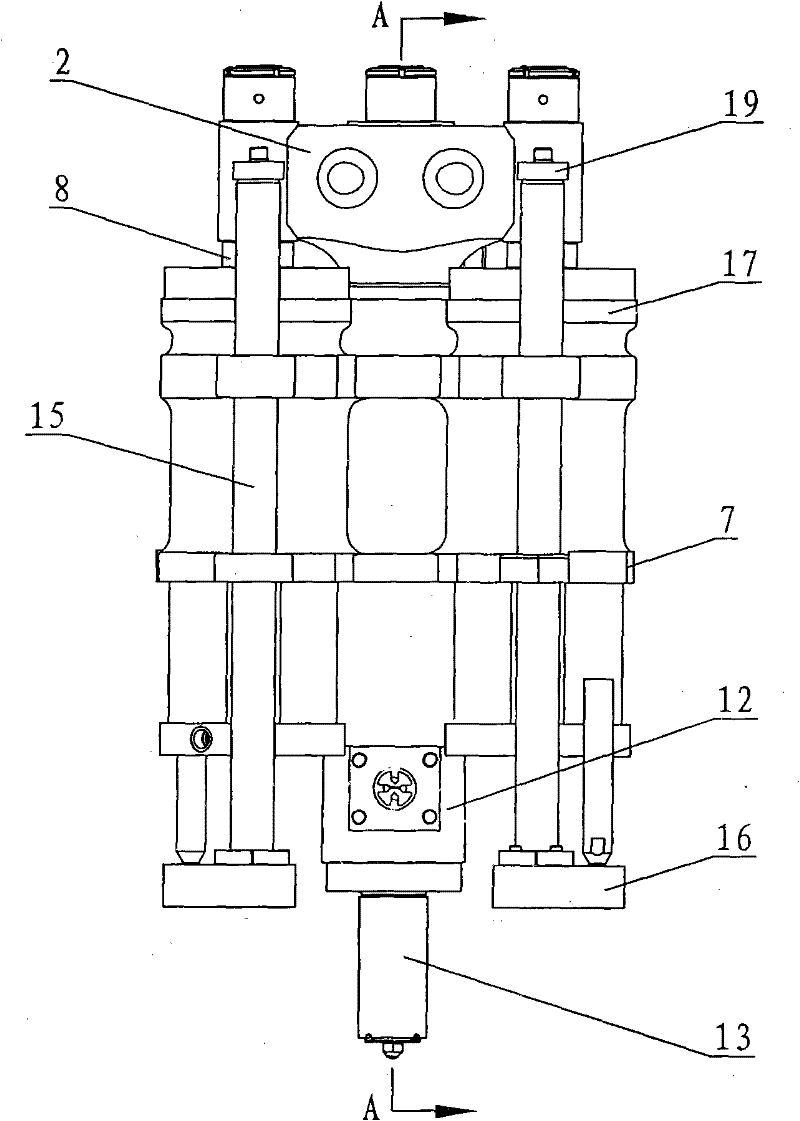

[0025] see Figure 1-Figure 6 The rubber injection machine has a balanced injection structure, including an upright injection barrel 12, the side is connected to the plasticizing part (not shown in the figure) at 90 degrees, and an injection plunger head 11 connected to the injection cylinder 17 is provided inside. , the lower end is directly equipped with a nozzle body 13, and the lower end of the nozzle body is provided with a nozzle 14.

[0026] There are three injection cylinders 17, which are evenly distributed in a triangle on the side of the injection cylinder 12, parallel to the injection cylinder, and fixedly connected to the injection cylinder through the oil cylinder support 7; the center of the injection cylinder is located at the center of gravity of the triangle. Its injection plunger head 11 is in drive connection with the piston rod 6 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com