High-performance magnesium alloy parison continuous casting production line

A magnesium alloy, high-performance technology, applied in the field of integrated complete equipment for high-strength deformed magnesium alloy parison continuous casting production, can solve problems such as continuous casting operation time conflicts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

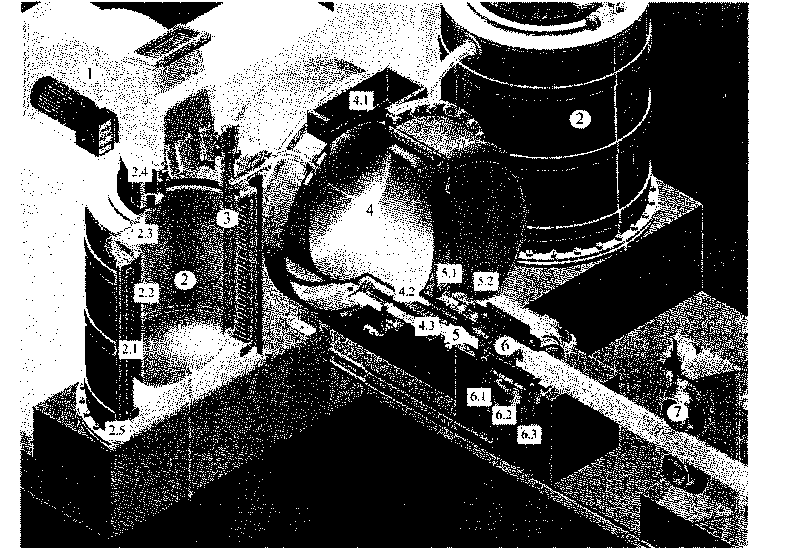

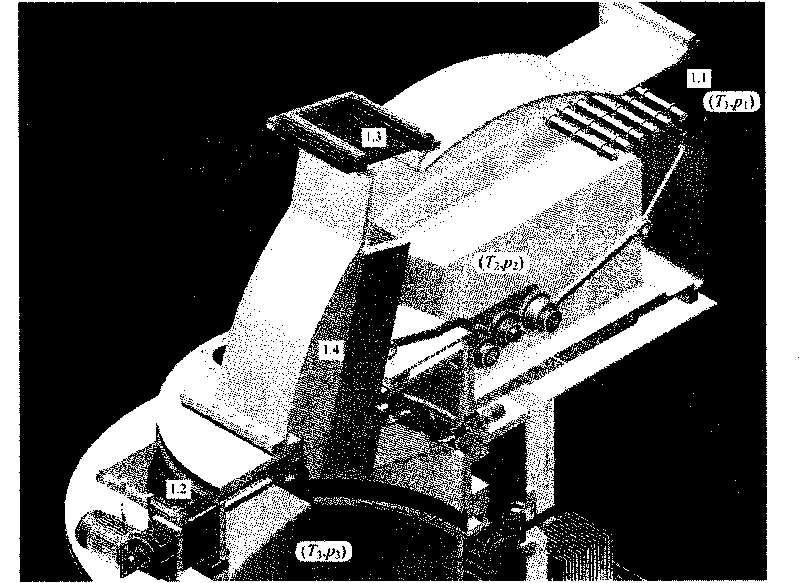

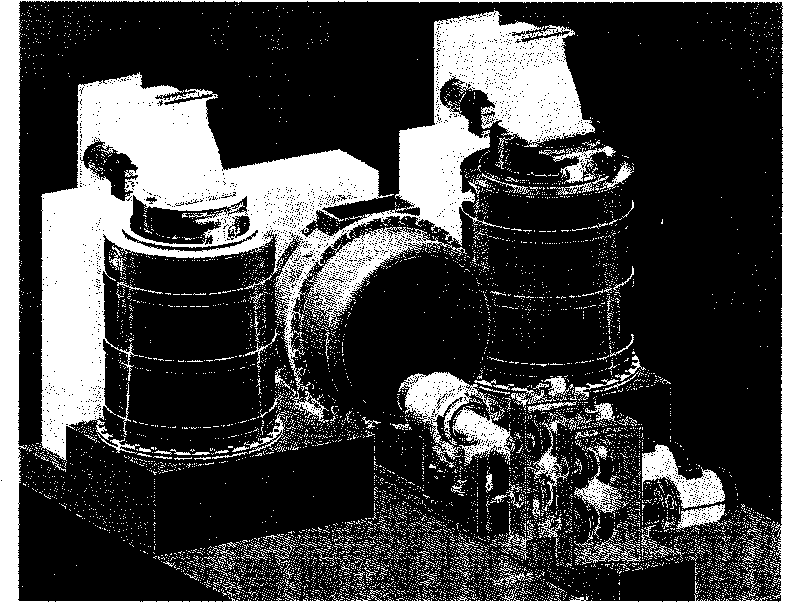

Image

Examples

Embodiment approach

[0008] The following measures are taken for the above purposes, that is, vacuum protection is used throughout the process, including the addition of raw materials in the furnace, the melting and preparation of magnesium alloy materials, the buffering of the heat preservation and homogenization furnace to ensure that the melting operation and continuous casting operation are synchronized in time, and the modification of liquid materials It works in a closed environment without external interference, and achieves the design goal of no pollution in the whole process. In addition, the raw materials used in the present invention do not refer to traditional casting master alloys and working alloys, but to use the lowest-end basic materials as far as possible, such as pure magnesium, a small amount and a small amount of supplementary pure metal or alloy materials, to reduce energy consumption and reduce pollution. link.

[0009] The present invention is characterized in that 1. feedi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com