Method for manufacturing high-power white light LED

A manufacturing method and high-power technology, applied in the field of lighting, can solve problems such as poor consistency and yellow circles, and achieve the effects of easy miniaturization, overcoming poor consistency, and low thermal deformation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the drawings and embodiments.

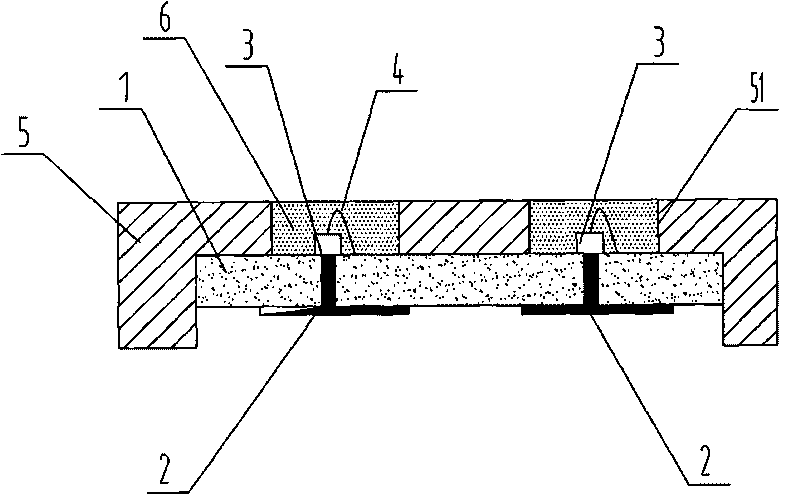

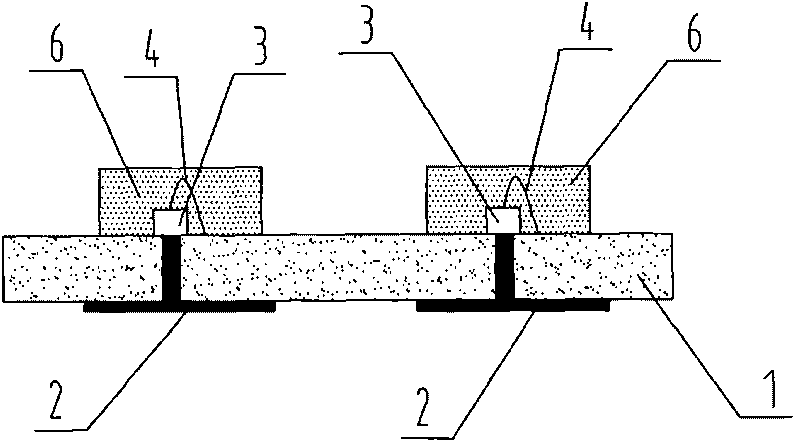

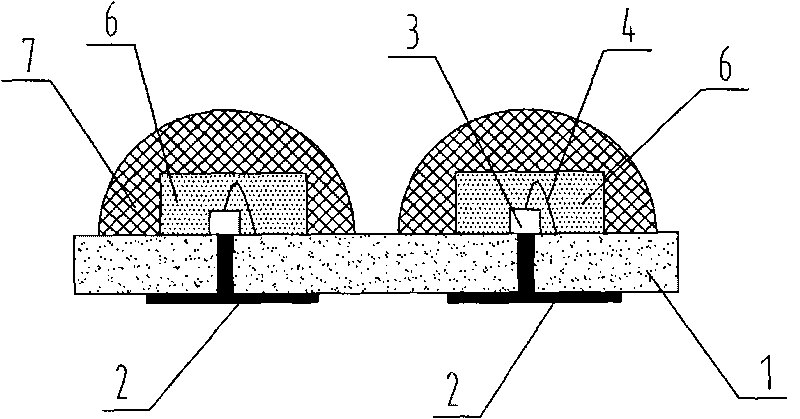

[0022] Such as Figure 1 ~ Figure 3 As shown, the present invention includes the following steps:

[0023] a. The ceramic substrate 1 covers the die attach area by electroplating high-reflectivity metallic silver or aluminum, which effectively increases the reflectivity of light; and is printed into a circuit.

[0024] b. Connect the heat sink 2 of high thermal conductivity copper alloy at the bottom of the ceramic substrate 1 by injecting silver into the holes.

[0025] c. Use high thermal conductivity silver glue with a thermal conductivity of 15w / m.k or more to fix the chip 3 with a length and width of 30mil (1mil=1 / 1000 inch=0.254mm) or more, and use gold wire 4 to solder and connect the circuit.

[0026] d. A porous metal template 5 is placed on the ceramic substrate 1, and each channel 51 contains a wire-bonded wafer 3, such as figure 1 Shown.

[0027] e. The phosphor and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com