Method for performing enzyme hydrolysis on wood fiber raw material

A lignocellulosic raw material and lignocellulosic technology, applied in the field of enzymatic hydrolysis, can solve problems such as impossible to meet, and achieve the effects of shortening time, reducing inhibition, and improving hydrolysis yield and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

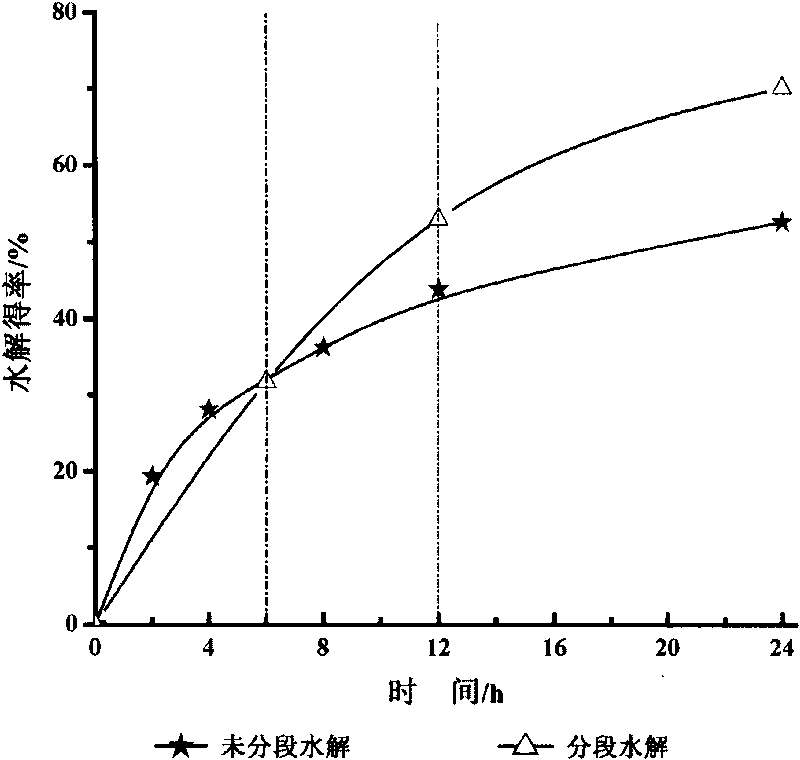

[0029] Example 1: Pretreatment of Corn Stalks by Cellulase Three-stage Hydrolysis and Steam Explosion

[0030] 1. Use corn stalks pretreated by steam explosion and water washing as lignocellulosic raw materials, the solid-liquid weight ratio is 1:3-20, the amount of cellulase is 5-25 FPIU / g cellulose, the pH value is 4-6, and the temperature is 45 Under the condition of ~50°C, low-speed agitation hydrolysis for 6 hours, followed by solid-liquid separation.

[0031] 2. Centrifuge the hydrolyzate at 4000 rpm for 10 min, collect the supernatant, measure the content of cellobiose and glucose in the sugar solution, and calculate the yield of cellulase hydrolysis. The enzymolysis residue obtained by centrifugation was washed twice with distilled water, centrifuged at 10,000 rpm for 5 min, and the supernatant and enzymolysis residue were collected respectively.

[0032] Determination of sugar concentration: using high performance liquid chromatography (HPLC) method. Chromatography ...

Embodiment 2

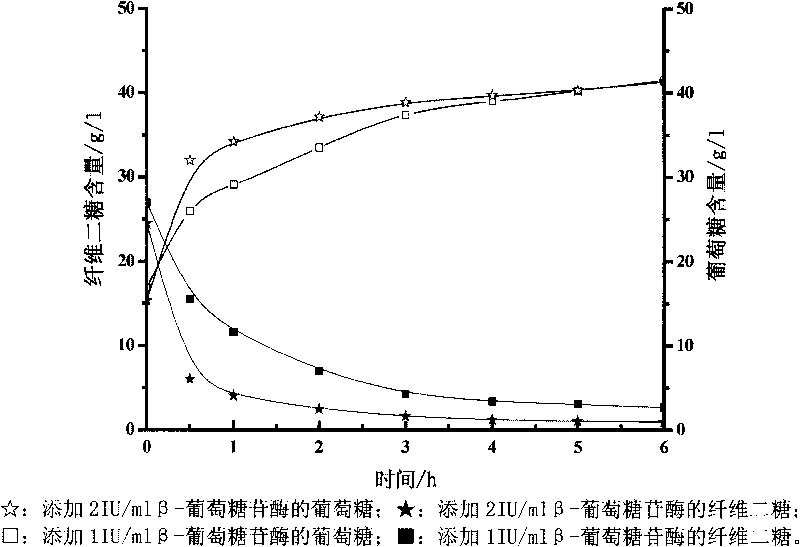

[0048] Example 2: Homogeneous hydrolysis of cellobiose sugar solution by β-glucosidase and recovery and reuse of β-glucosidase by ultrafiltration

[0049] 1. Combine the sugar liquid obtained by segmental hydrolysis in Example 1, evaporate and concentrate under reduced pressure until the concentration of cellobiose is 30g / L.

[0050] 2. Add β-glucosidase, buffer and distilled water to the above-mentioned concentrated sugar solution, the addition amount of β-glucosidase is 1 and 2IU / ml respectively, control the pH value of the hydrolysis system to 4-6, and the temperature of 45-50°C Stir at low speed and hydrolyze for 1-6 hours.

[0051] 3. After the hydrolysis, measure the content of cellobiose and glucose in the hydrolyzate, and calculate the hydrolysis yield of cellobiose hydrolyzed by β-glucosidase. The β-glucosidase in the hydrolyzate was recovered by an ultrafiltration membrane with a molecular weight cut-off of 30kDa, the enzyme activity of the β-glucosidase was measure...

Embodiment 3

[0055] Example 3: Cellulase two-stage hydrolysis steam explosion pretreatment of corn stalks

[0056] Referring to the method of Examples 1 and 2, the process is simplified by adopting (12+12)h two-stage hydrolysis method, and the 24h cellulose hydrolysis yield is about 59.12%. See the following table for the stage-by-stage yield of two-stage or three-stage enzymatic hydrolysis process:

[0057] Segmented enzymatic hydrolysis results of steam-exploded corn stalks

[0058]

[0059] Regardless of the two-stage method or the three-stage method of enzymatic hydrolysis process, the specific subsection time of solid-liquid separation can be changed within a certain range considering the convenience of production scheduling.

[0060] Although the efficiency and yield of enzymatic hydrolysis can be improved to a certain extent by adopting more staged solid-liquid separation treatment process, it will increase the cost of treatment, so it is not considered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com