Method for separating and extracting compound of Amadori of Maillard reaction midbody

A technology of reaction mixtures and compounds, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of high cost of ion exchange resins, impossibility of industrial production, slow elution of cationic resins, etc., and achieve good application Prospects, short purification time, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

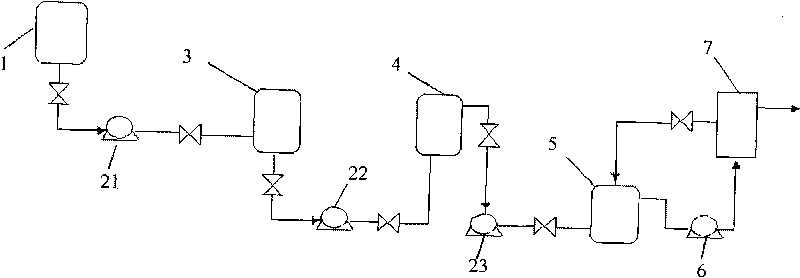

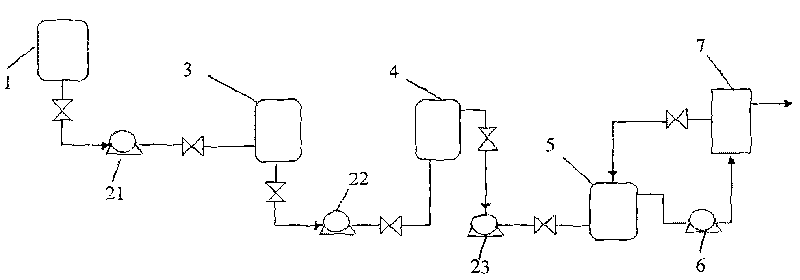

[0030] see figure 1 , Preparation of Amadori compound 1-valine-1-deoxy-D-fructose (Fru-Val) by nanofiltration

[0031] Add 20mol of anhydrous glucose, 25mol of valine, and 30L of anhydrous methanol into the 50L reactor 1, heat and stir to dissolve, set the reflux temperature of the reactor 1 to 75°C, and the reflux time to 5 hours; The feed pump 21 is pumped into the vacuum concentration tank 3, and the dry material is obtained by vacuum concentration at 50°C and a vacuum degree of -0.03Mpa, and 10L of soft water is added to the dry material for dissolution to obtain an aqueous solution of the reaction mixture, which is passed through the secondary feed pump 22. Pump the aqueous solution of the reaction mixture into the fine filter 4 and filter through the fine filter 4 to remove particles that may exist in the aqueous solution of the reaction mixture to prevent damage to the nanofiltration membrane or ultrafiltration membrane. The output of the fine filter 4 passes through a ...

Embodiment 2

[0033] see figure 1 , Preparation of Amadori compound 1-phenylalanine-1-deoxy-D-fructose (Fru-Phe) by ultrafiltration and nanofiltration combined method

[0034] Add 20 mol of anhydrous glucose, 22 mol of phenylalanine, 3 mol of malonic acid, and 30 L of anhydrous methanol into the 50L reactor 1, heat and stir to dissolve, set the reflux temperature of the reactor 1 to 75°C, and the reflux time to 4 hours. Reaction After the completion, the primary feed pump 21 pumps it into the vacuum concentration tank 3, concentrates in vacuum at 50°C (vacuum degree is -0.03Mpa) to dryness, adds 10L of soft water to dissolve, and obtains an aqueous solution of the reaction mixture, which is passed through the secondary feed pump 21 Pump into the fine filter 4, after being filtered by the fine filter 4, the output of the fine filter 4 is pumped into the feed liquid tank 5 through the three-stage feed pump 23, and the feed liquid in the feed liquid tank 5 is then pressed into the diafiltratio...

Embodiment 3

[0036] see figure 1 , Preparation of Amadori Compound 1-Proline-1-Deoxy-D-Fructose (Fru-Pro) by Nanofiltration

[0037] Add 10 mol of anhydrous glucose, 15 mol of proline, and 30 L of absolute ethanol into the 50L reactor 1, heat and stir to dissolve, set the reflux temperature of the reactor 1 to 75°C, and the reflux time to 7 hours. After the reaction is completed, the primary feed pump 21 pumps it into the vacuum concentration tank 3, concentrates in vacuum at 50°C (vacuum degree is -0.03Mpa) to dryness, adds 5L of soft water to dissolve, and obtains an aqueous solution of the reaction mixture, which is passed through the secondary feed pump 21. Pump the aqueous solution of the reaction mixture into the fine filter 4. After filtering through the fine filter 4, the discharge of the fine filter 4 is pumped into the feed liquid tank 5 through the three-stage feed pump 23, and the feed liquid in the feed liquid tank 5 passes through the high-pressure pump 6. Press into the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com