Wheel braking stored-energy machine

A wheel and energy storage technology, applied in brakes, brake components, transportation and packaging, etc., can solve problems such as noise, vibration, waste of people, money, material resources, safety and security, etc., to achieve energy saving, reliable work, and ensure The effect of the safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

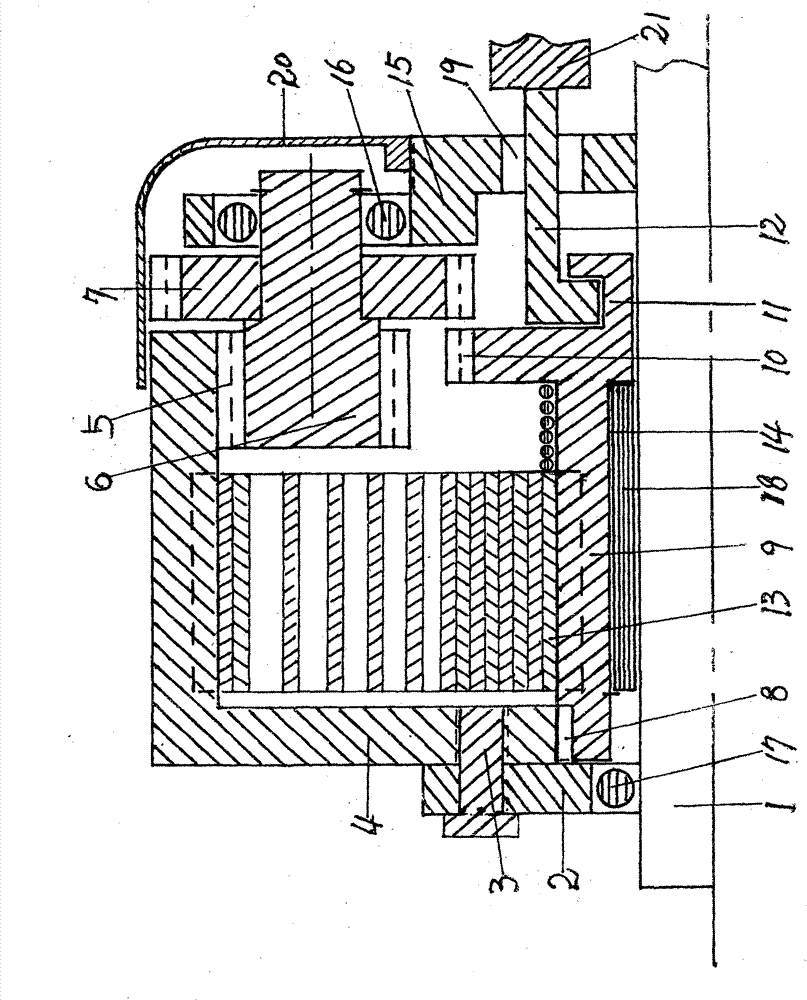

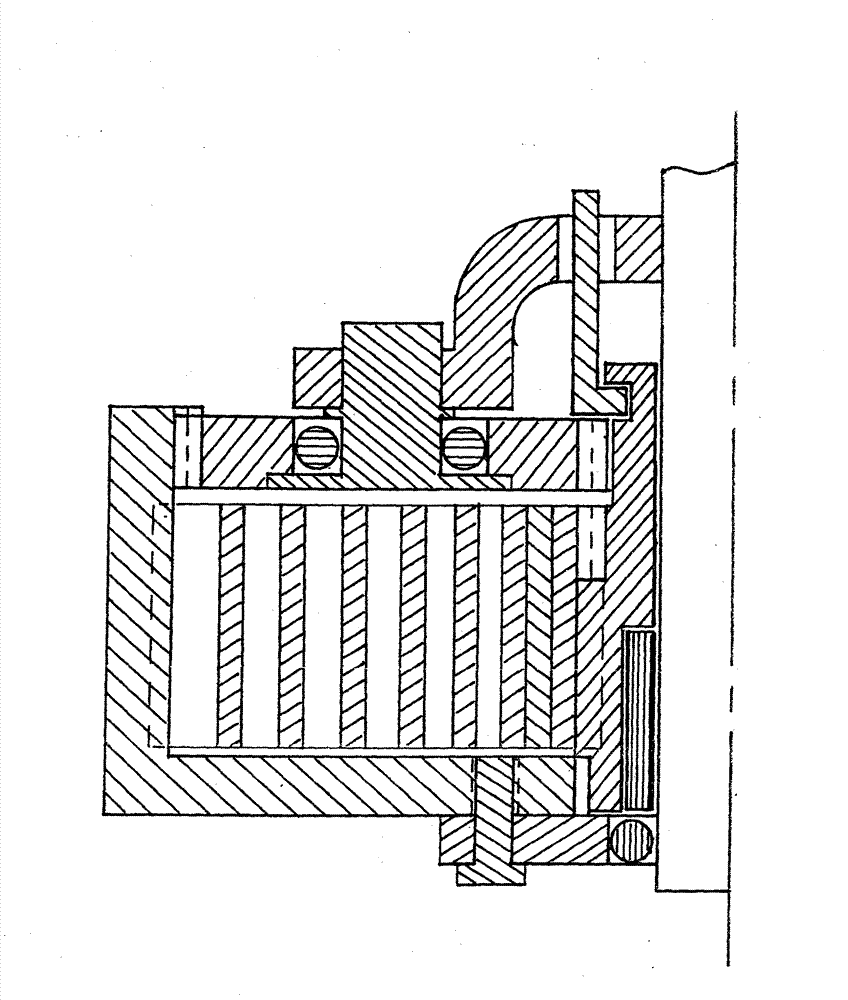

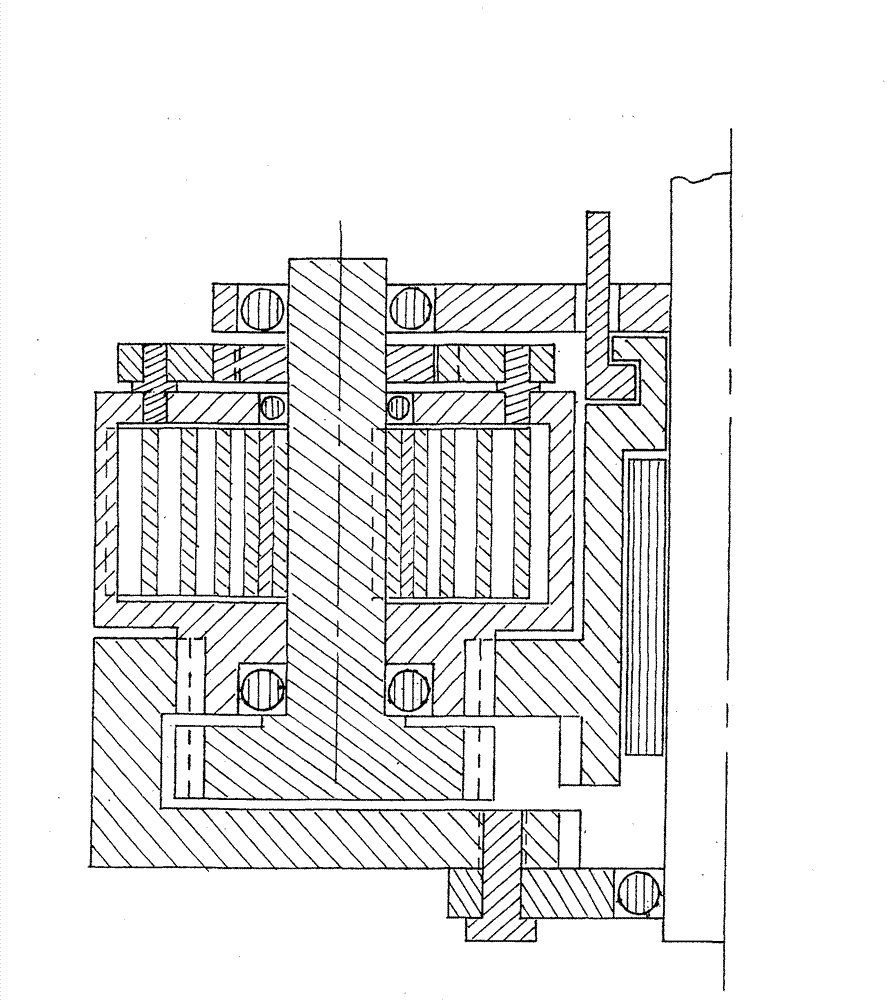

[0012] exist figure 1 Among them, shaft 1 and roulette 2 are prior art. Screw 3, the housing 4 is connected to the wheel disc 2, the housing 4, the ring gear 5, and the mechanical method is integrated, the primary gear 6, the intermediate gear 7, and the coaxial bearing 16 are installed on the bracket 15, and the bracket 15 Fixed on the shaft 1, one end of the roller assembly has a spline 8, which is combined with the housing 4, and the other end has a gear 10 and a control mechanism 11, which are installed on the shaft 1 through a sliding bearing 18, and the outer end of the energy storage spring 13 is fixed On the inner wall of the housing 4, the inner end is fixed on the position of the drum 9 of the drum assembly, the limit spring 14 is sleeved on the drum 9, one end of the operating mechanism 12 cooperates with the control mechanism 11, and the other end passes through the hole 19 and stretches out. Contact with relevant parts of power mechanism, (external power mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com