Compound isolating film and formation method thereof

A technology of separator and polymer solution, applied in electrical components, circuits, battery pack parts, etc., can solve the problems of unsatisfactory performance of polymer electrolyte, need to improve mechanical strength, low market share, etc. Liquid capacity and ion penetration capacity, improve the safety of production operations, and reduce the effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

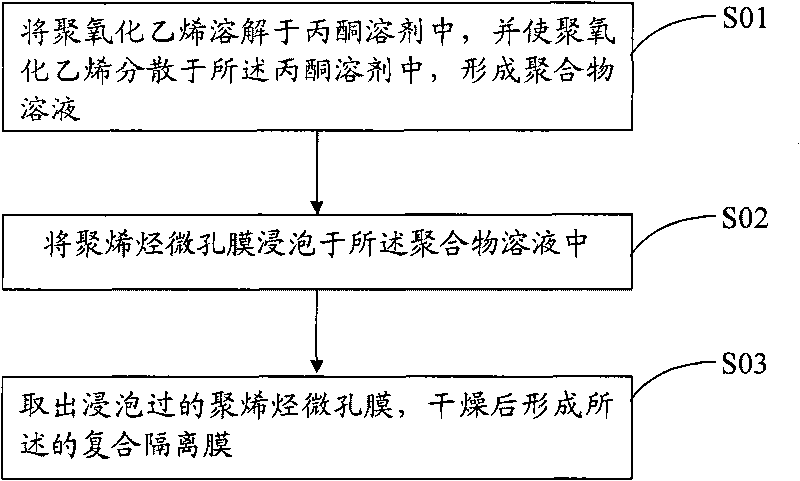

[0031] Weigh 2.0 g of PEO with an electronic balance, pour it into a flask filled with 100 ml of acetone, and heat and stir it in a constant temperature water bath furnace at 40°C for 3 hours. After the PEO is completely dissolved, transfer it to an ultrasonic disperser Disperse for 30 minutes to make the solution evenly dispersed.

[0032] Soak the polypropylene microporous membrane in the polymer solution prepared above for 15 minutes in an oven at 40°C, take it out, and dry it in a vacuum drying oven at 50°C for 24 hours after the acetone volatilizes at room temperature. After the acetone is completely volatilized, a composite isolation film is formed.

Embodiment 2

[0034] Weigh 1.5 g of PEO with an electronic balance, pour it into a flask filled with 100 ml of acetone, and heat and stir it in a constant temperature water bath furnace at 40°C for 3 hours. After the PEO is completely dissolved, transfer it to an ultrasonic disperser Disperse for 30 minutes to make the solution evenly dispersed.

[0035] Soak the polypropylene microporous membrane in the polymer solution prepared above for 15 minutes in an oven at 40°C, take it out, and dry it in a vacuum drying oven at 50°C for 24 hours after the acetone volatilizes at room temperature. After the acetone is completely volatilized, a composite isolation film is formed.

Embodiment 3

[0037] Weigh 2.0 grams of PEO with an electronic balance, pour it into a flask filled with 100 ml of acetone, and heat and stir it in a constant temperature water bath furnace at 45°C for 3 hours. After the PEO is completely dissolved, transfer it to an ultrasonic disperser Disperse for 30 minutes to make the solution evenly dispersed.

[0038] Soak the polypropylene microporous membrane in the polymer solution prepared above for 15 minutes in an oven at 45°C, take it out, and dry it in a vacuum drying oven at 50°C for 24 hours after the acetone has evaporated at room temperature. After the acetone is completely volatilized, a composite isolation film is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com