Intelligent AMT gearbox

A transmission, intelligent technology, applied in the direction of gear transmission, toothed components, belt/chain/gear, etc., can solve the impact problem of AMT transmission that cannot be effectively solved, the rotational speed of the active friction plate and the driven friction plate are inconsistent, Restrict the development of AMT transmission and other issues, to achieve the effect of easy recovery and idling power generation, smooth shifting, and non-impact shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

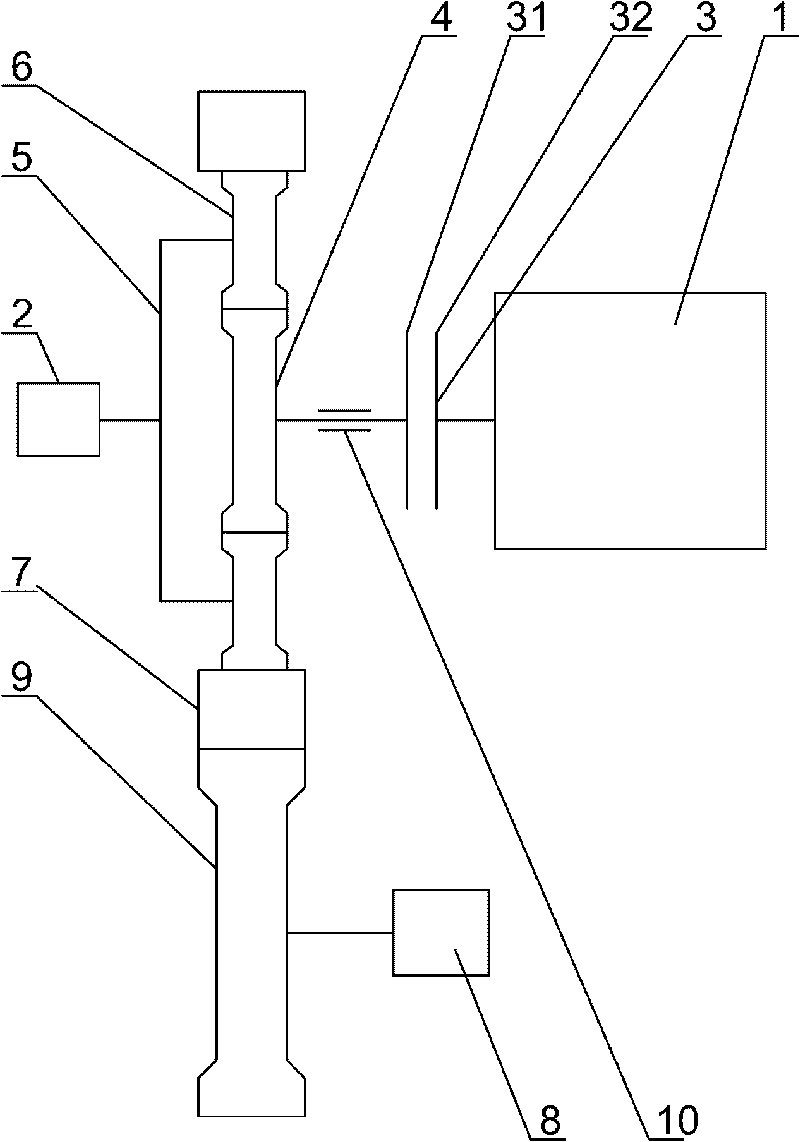

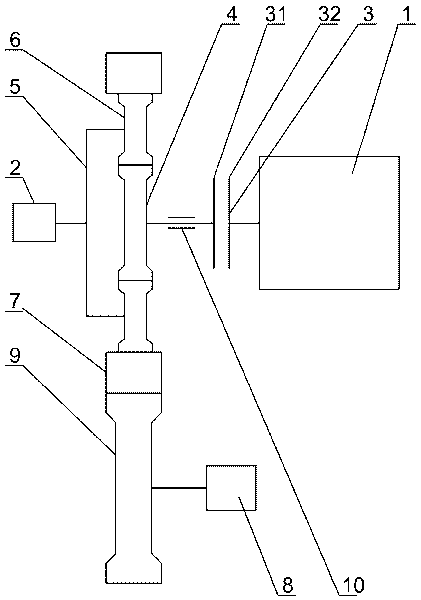

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

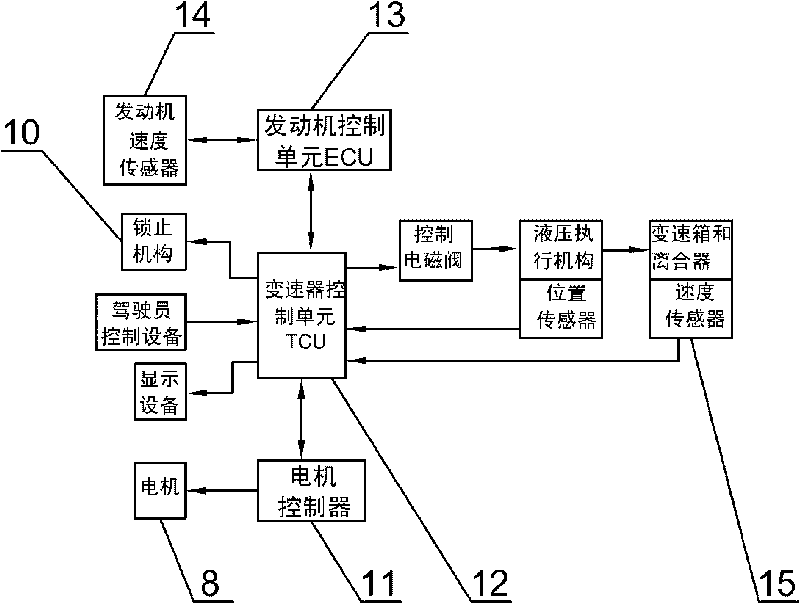

[0009] Such as figure 1 , figure 2 In the shown embodiment, the intelligent AMT transmission of the present invention includes an AMT transmission 1 and a friction clutch 3 connected with the AMT transmission 1, and a planetary gear transmission system is set between the friction clutch 3 and the engine crankshaft 2, and the planetary The sun gear 4 of the gear transmission system is coaxially connected with the active friction plate 31 of the friction clutch 3, and its planet carrier 5 is coaxially connected with the crankshaft 2 of the engine. The motor gear 9 engaged with the ring gear 7 is set on the 8 shaft, the transmission ratio of the motor gear 9 and the ring gear 7 is 1:1, and the locking mechanism 10 is set on the sun gear 4 rotating shaft. In addition, the intelligent AMT transmission of the present invention It also includes a motor controller 11 for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com