Brick for construction and preparation method thereof

A technology for building and bricks, applied in building materials, manufacturing tools, climate change adaptation and other directions, can solve the problems of low compressive strength and easy breakage, and achieve the effect of high compressive strength, low cost and saving land resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

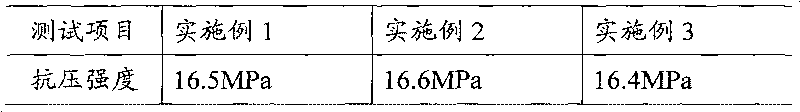

Embodiment 1

[0017] A preparation method of the building bricks, comprising the steps of:

[0018] (1), get 50 parts of stone powder slag, 40 parts of sea mud, 15 parts of fly ash and 15 parts of shale, stir and mix, then add water of 5% of the total weight of the mixed material, and stir to form a slurry;

[0019] (2), the slurry that step (1) is made is transported in the brick mould, carries out mechanical molding, obtains brick adobe;

[0020] (3), the adobe is dried in the drying device, or dried naturally, to a moisture content of 38%;

[0021] (4) The brick adobe dried in step (3) is placed in a kiln for firing at a temperature of 1200° C. for 24 hours; then the temperature is controlled at 1000±20° C. for 48 hours to obtain building bricks.

Embodiment 2

[0023] A preparation method of the building bricks, comprising the steps of:

[0024] (1), get 70 parts of stone powder slag, 30 parts of sea mud, 20 parts of fly ash and 10 parts of shale, stir and mix, then add water with 5% of the total weight of the mixed material, and stir to form a slurry;

[0025] (2), the slurry that step (1) is made is transported in the brick mould, carries out mechanical molding, obtains brick adobe;

[0026] (3), the adobe is dried in the drying device, or dried naturally, until the moisture content is 35%;

[0027] (4) The brick adobe dried in step (3) is placed in a kiln for firing at a temperature of 950° C. for 24 hours; then the temperature is controlled at 1000±20° C. for 48 hours to obtain building bricks.

Embodiment 3

[0029] A preparation method of the building bricks, comprising the steps of:

[0030] (1), get 60 parts of stone powder slag, 35 parts of sea mud, 18 parts of fly ash and 12 parts of shale, stir and mix, then add water of 5% of the total weight of the mixed material, and stir to form a slurry;

[0031] (2), the slurry that step (1) is made is transported in the brick mould, carries out mechanical molding, obtains brick adobe;

[0032] (3), the adobe is dried in the drying device, or dried naturally, until the moisture content is 30%;

[0033] (4) The adobe dried in step (3) is placed in a kiln for firing at a temperature of 1000° C. for 24 hours; then the temperature is controlled at 1000±20° C. for 48 hours to obtain building bricks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com