Preparation method of cationic terpenyl epoxy resin polyalcohol water dispersoid and application thereof

A type of terpene-based epoxy resin and terpene-based epoxy resin technology are applied in the field of preparation and application of cationic terpene-based epoxy resin polyol water dispersion, and can solve the problem that the molecular weight of polyurethane polyol is difficult to control and the viscosity is high. and other problems, to achieve the effects of excellent mechanical properties, simple manufacturing method, and clean manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

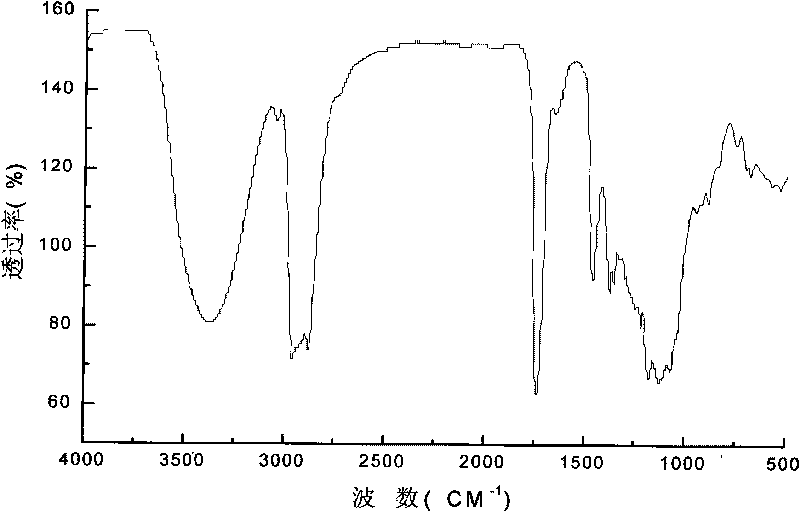

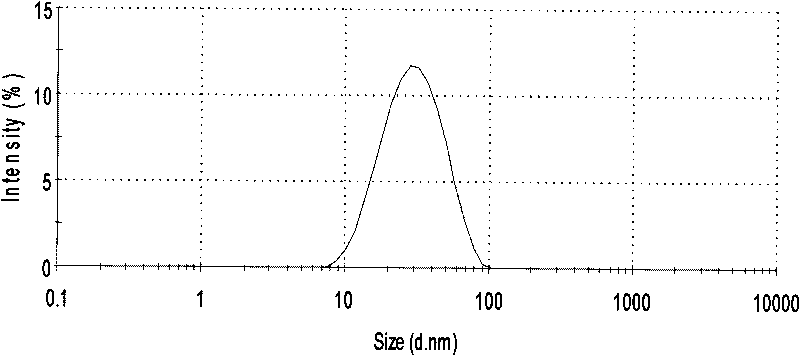

[0023] In a three-necked flask equipped with a thermometer, a stirrer, and a condenser tube, add 48.8g TME, 5.9g DEA, 14.3g polyethylene glycol 200, and 0.976g zinc chloride respectively, heat and stir, and react at 100°C for 7h; After finishing, cool to 70°C, neutralize the product with 3.2g acetic acid (diluted in 5.0g water), and then stir and disperse with deionized water to obtain a yellow transparent polyol water dispersion with a hydroxyl value of 248mg g -1 (solid resin), viscosity 2.047Pa s (25 ℃, 30% solid content), Z average particle size 35.4nm, the infrared spectrum of gained polyhydric alcohol is as follows figure 1 shown.

[0024] Take 20.0g of the above-mentioned polyol aqueous dispersion (30% solid content), add 9.6g of hydrophilic modified polydiisocyanate EC385 and 2.0g of PMA, mix and stir evenly by hand, paint a film, and test the paint after 7 days of maintenance at room temperature The membrane properties are listed in Table 1.

Embodiment 2

[0026] Add 36.5g TME, 4.4g DEA, and 4.8g 1,4-butanediol respectively to a three-necked flask equipped with a thermometer, agitator, and condenser, heat and stir evenly, and add 0.3ml titanium tetrachloride at 70°C, Raise the temperature to about 105°C and continue the reaction for 3 hours; after the reaction, cool to 65°C, neutralize the product with 2.4g of acetic acid (diluted in 5.0g of water), and then stir and disperse with deionized water to obtain a yellow transparent polyol aqueous dispersion. Hydroxyl value 288mg·g -1(solid resin), viscosity 2.451Pa·s (25°C, 30% solid content), Z-average particle size 40.2nm.

[0027] Take 20.0g of the above-mentioned polyol aqueous dispersion (30% solid content), add 10.9g of hydrophilic modified polydiisocyanate EC385 and 2.0g of PMA, mix and stir evenly by hand, paint a film, and test the paint after 7 days of maintenance at room temperature The membrane properties are listed in Table 1.

Embodiment 3

[0029] Add 35.1g TME, 4.2g DEA, 5.5g diethylene glycol and 0.702g zinc chloride to a three-necked flask equipped with a thermometer, agitator, and condenser respectively, heat and stir, and react at 100°C for 7h ; Cool to 70°C after the end, neutralize the product with 2.3g acetic acid (diluted in 5.0g water), then stir and disperse with deionized water to obtain a yellow transparent polyol water dispersion with a hydroxyl value of 277mg g -1 (solid resin), viscosity 2.221Pa·s (25°C, 30% solid content), Z-average particle size 36.9nm, TME epoxy value between 0.32-0.39mol / 100g.

[0030] Take 20.0g of the above-mentioned polyol aqueous dispersion (30% solid content), add 10.6g of hydrophilic modified polydiisocyanate EC385 and 2.0g of PMA, mix and stir evenly by hand, paint a film, maintain it at room temperature for 7 days, and then measure the paint The membrane properties are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com