Vehicle body braking electrical power generating system

A technology for braking power generation and car body, which is applied to electric braking systems, electric vehicles, vehicle components, etc., can solve the problems of increased brake pad wear and low kinetic energy recovery rate during the deceleration stage of the car body, and achieves improved kinetic energy utilization, The effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

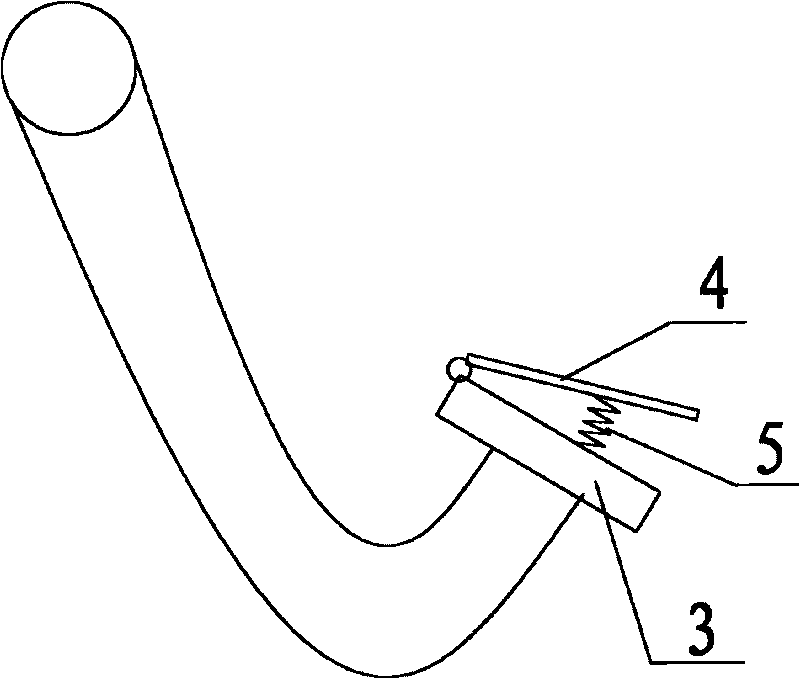

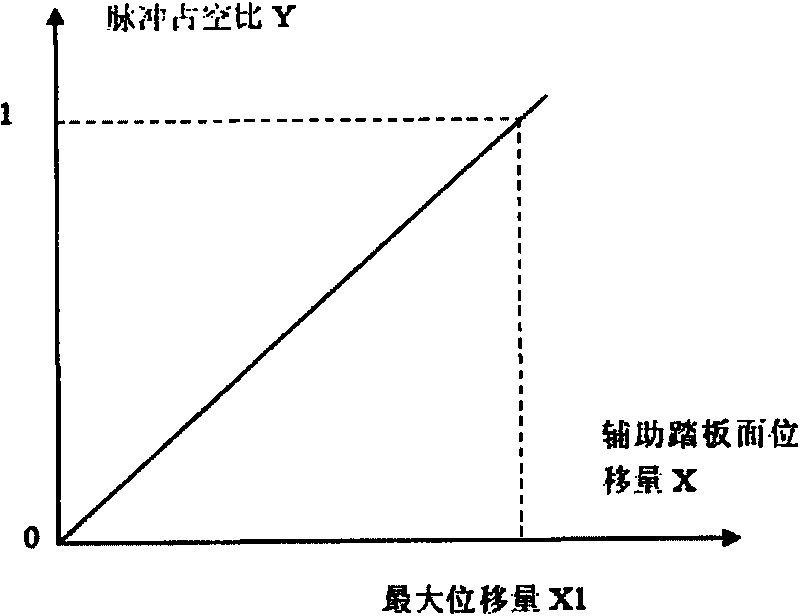

[0018] This embodiment includes a brake pedal mechanism, a power generation brake device and a mechanical brake device, the brake pedal mechanism has a braking stroke section, and the brake pedal mechanism also has a free travel mechanism before the brake stroke section, in the free stroke mechanism There is a stroke sensor, the signal output end of the stroke sensor is connected to the control end of a switch circuit, and the switch circuit is connected in series between the generator stator coil of the generator braking device and the corresponding load, when only the free travel mechanism acts on the brake pedal , the generator braking device works and the mechanical brake device does not work; when the brake pedal is in the braking stroke section, the generator brake device and the mechanical brake device work simultaneously.

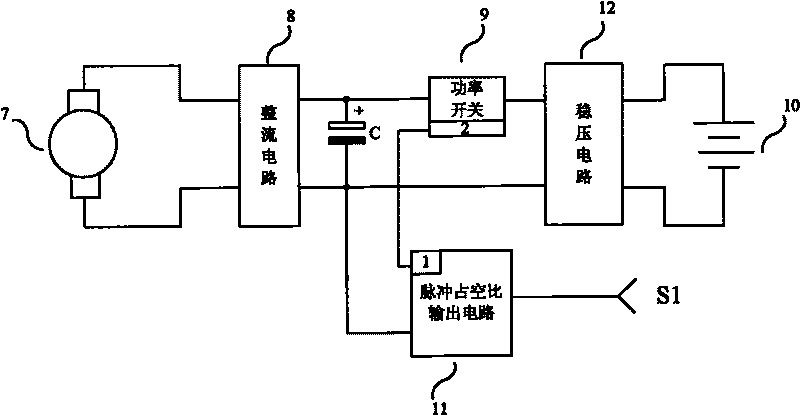

[0019] like figure 1 As shown, the generator braking device includes a generator 7, a rectification circuit 8, a power switch 9, a voltage stabiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com