Thermosetting resin glass fiber laminating composite material and preparation method thereof

A composite material and thermosetting technology, applied in the direction of chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the problems of restricted application, high price of carbon fiber, etc., and achieve easy production and processing, and integration of electromagnetic wave absorption performance , the effect of high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of 4-aminophenoxy group-phthalonitrile monomer is:

[0023] Mix 4-nitrophthalonitrile, p-aminophenol, catalyst, and solvent, blow in nitrogen to replace the air, raise the temperature to 80-90°C for 4-8 hours, and pour the reaction mixture into 0.1M Precipitate in NaOH aqueous solution, filter and dry to obtain 4-aminophenoxy-phthalonitrile monomer.

[0024] The preparation method of two-terminal phthalonitrile-benzoxazine resin is:

[0025] Mix the dry 4-aminophenoxy-phthalonitrile monomer, bisphenol A, and solvent evenly, blow in nitrogen to replace the air in it, add paraformaldehyde in stages, and control the temperature at about 60°C when adding After the addition, the temperature is raised to 70-120° C. to continue the reaction for 3-5 hours; the reaction mixture is washed with hot water and vacuum dehydrated at 85-110° C. to obtain a double-terminated phthalonitrile-benzoxazine resin.

[0026] The preparation method of thermosetting resin...

Embodiment 1

[0036] Example 1 Preparation of double-terminated phthalonitrile-benzoxazine resin

[0037] (1) Synthesis of 4-aminophenoxy group-phthalonitrile: the raw material formula component is (by mole):

[0038] 4-Nitrophthalonitrile 1

[0039] p-Aminophenol 1

[0040] Anhydrous Potassium Carbonate 1.1

[0041] Dimethyl sulfoxide 15

[0042] (2) Synthesis of double-ended phthalonitrile-benzoxazine resin:

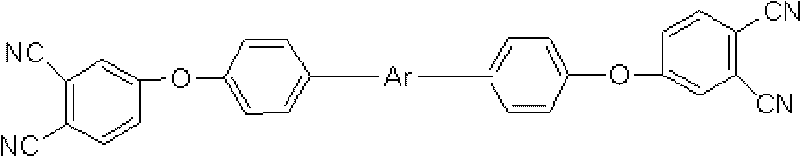

[0043]

[0044] Among them, Ar is:

[0045]

[0046] Raw material formula component is (by mole):

[0047] 4-Aminophenoxy-phthalonitrile 2

[0048] Bisphenol A 1

[0049] Paraformaldehyde 4

[0050] 1,4-dioxane / toluene (molar ratio 3:1) 15

[0051] Add 4-nitrophthalonitrile, p-aminophenol, anhydrous potassium carbonate, and dimethyl sulfoxide into a four-necked flask, pass through nitrogen to replace the air in it, raise the temperature, and react at 80-90°C Stop the reaction after 5 hours, pour the reaction mixture into 0.1M NaOH aqueous solution to precipitate, fil...

Embodiment 2

[0053] Embodiment 2 Preparation of thermosetting resin glass fiber laminated composite material

[0054] The raw material consumption is (by mass fraction):

[0055] Double-ended phthalonitrile-benzoxazine resin 100 parts

[0056] Glass fiber cloth 85 parts

[0057] Micron carbonyl iron powder 30 parts

[0058] Acetone 100 parts

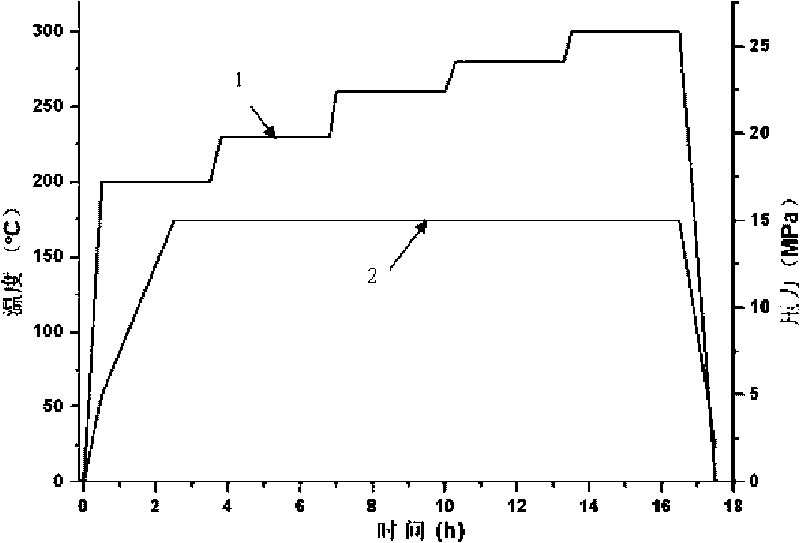

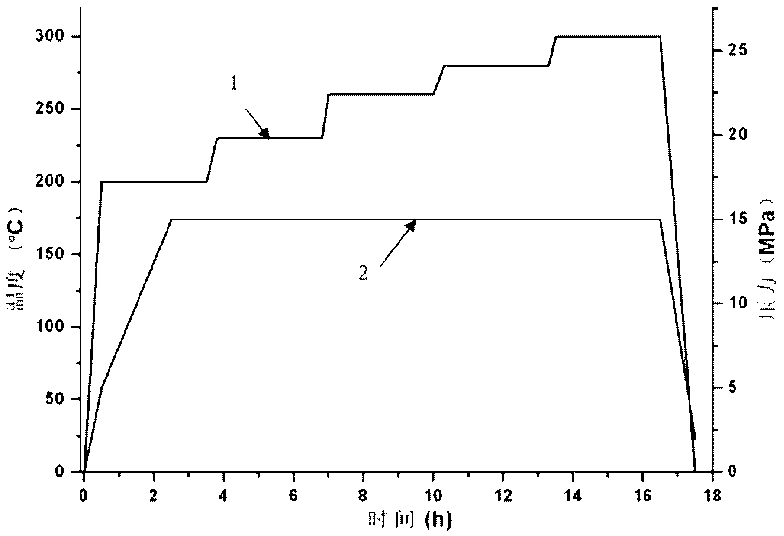

[0059] Dissolve the thermosetting resin containing benzoxazine ring in acetone, add micron-sized carbonyl iron powder, and disperse with vigorous mechanical stirring for half an hour. Then cut the glass fiber cloth into a size of 20cm×20cm and stack it neatly, fully soak it in the dispersed mixed solution, dry it naturally, place it in a high-temperature oven at 160°C to evaporate the excess solvent after overnight drying, and then cool it naturally to obtain Prepreg. The prepreg is placed in a metal mold and pressed in a 15-ton hydraulic press. At the beginning, 1 / 3 of the pressure is applied to remove the interlayer air several times. For spec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com