Method for processing high-precision thin-wall metal shell coated with glass fibre reinforced plastics

A metal shell and processing method technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problem of poor flatness of the composition plane, easy occurrence of peeling, slag, expansion, bonding force, and adhesion Small and other problems, to achieve good flatness, small deformation, good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

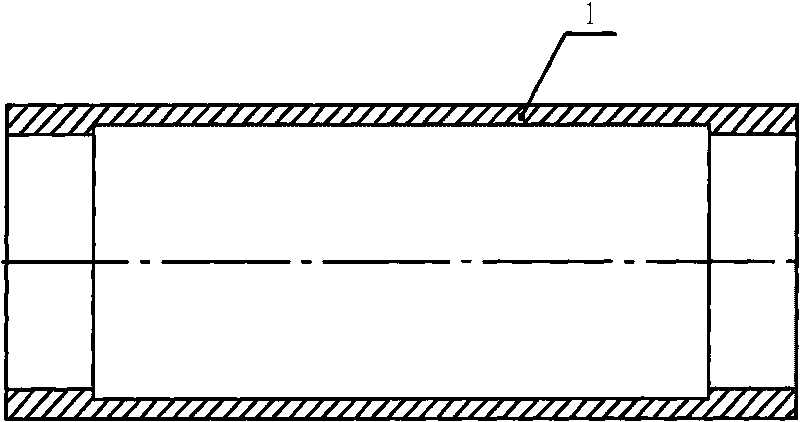

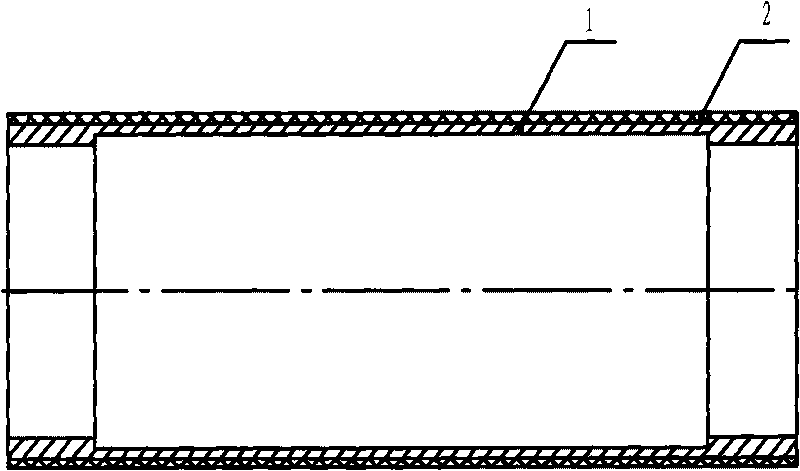

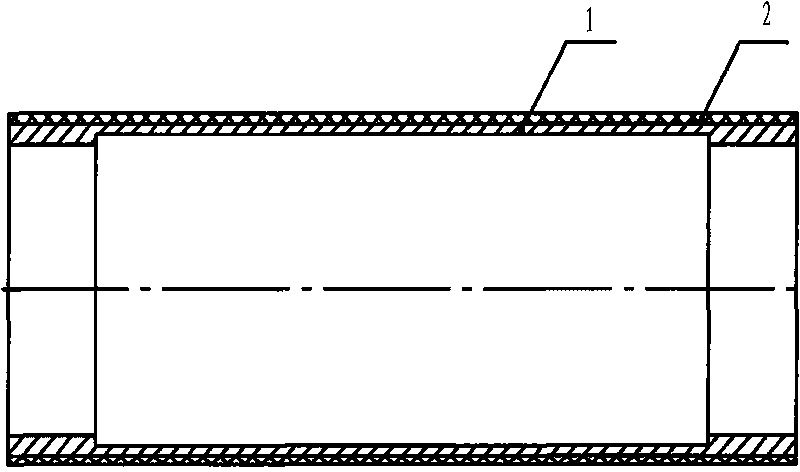

[0015] like figure 1 , 2 As shown, the processing method of the high-precision thin-walled metal shell coated with glass fiber reinforced plastics, the processing steps are as follows:

[0016] 1) In the step of winding and coating, the FRP 2 is made into a strip shape, and the surface is coated with glue and wound on the surface of the metal shell 1 layer by layer;

[0017] 2), FRP curing step, first curing at 80°C for 5-6 hours; then curing at 60°C for 4-6 hours;

[0018] 3), the step of cutting the surface of FRP, cutting the surface of FRP with a diamond tool, and ensuring that the cutting direction of the diamond tool is consistent with the winding direction of the ribbon FRP, and the cutting parameters are cutting speed v=15~20m / s, cutting depth a p =0.2~0.5mm, feed f=0.05~0.1mm / rev;

[0019] 4), the finishing process step, finishing turning the metal surface and the FRP surface of the shell end face, first processing the FRP surface of the shell end face with a diamo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com