Cutter grinding machine

A knife sharpening machine and sliding component technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, abrasive surface adjustment devices, etc. The effect of improvement, efficiency and service life improvement, and service life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

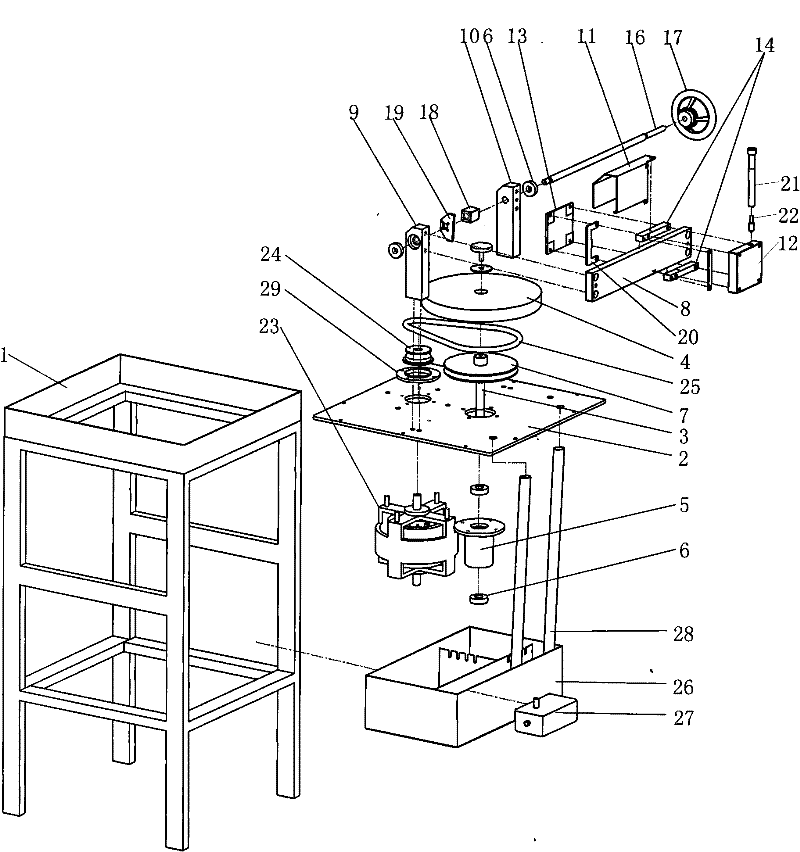

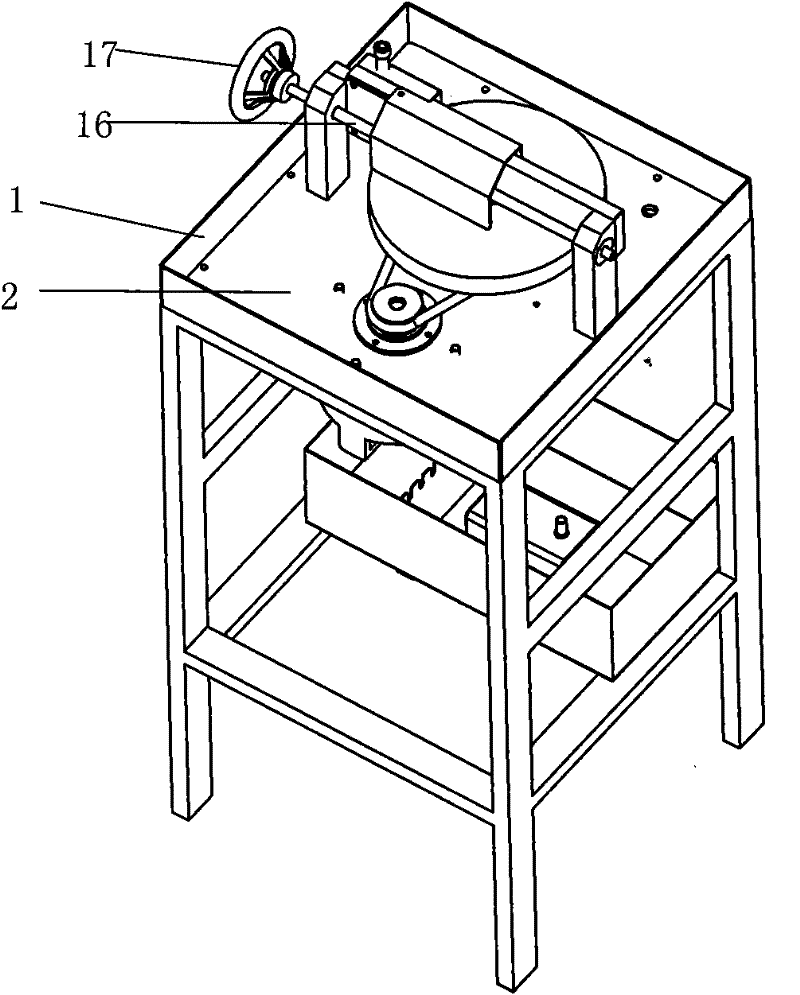

[0015] refer to figure 1 , figure 2 , a kind of sharpening machine disclosed by the present invention comprises a bracket 1, a grinding wheel fixing plate 2 is installed on the bracket 1, a grinding wheel 4 is installed on the grinding wheel fixing plate 2 through a transmission shaft 3, and a power transmission device is connected to the transmission shaft 3, and Using the grinding wheel instead of the steel wheel, the grinding wheel can be corrected at any time and frequently, and the efficiency and service life are significantly improved. As shown in the figure, in order to facilitate the installation of the transmission shaft, a drum 5 is fixed on the lower part of the grinding wheel fixing plate 2, and a bearing 6 is installed in the drum 5, and the bearing 6 is fixed on the transmission shaft 3, and a large pulley is installed on the transmission shaft 3 7.

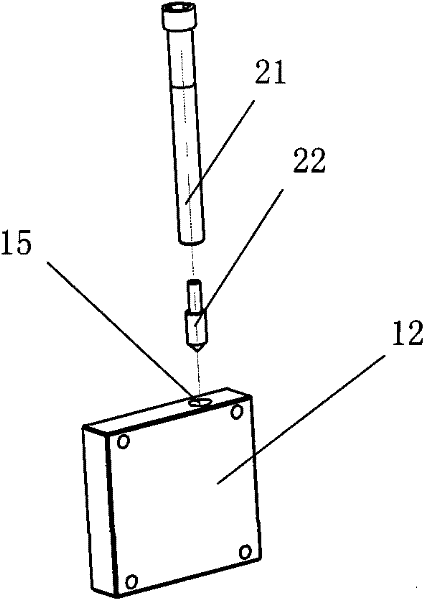

[0016] A grinding wheel correction device is installed on the bracket 1, and the grinding wheel correction dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com