Low pressure casting method for lattice sandwich plate

A low-pressure casting and sandwich panel technology, used in casting molding equipment, molds, cores, etc., can solve the problems of high defect rate and difficulty in forming lattice sandwich panels, achieving low defect rate, complete molding, Good overall casting formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

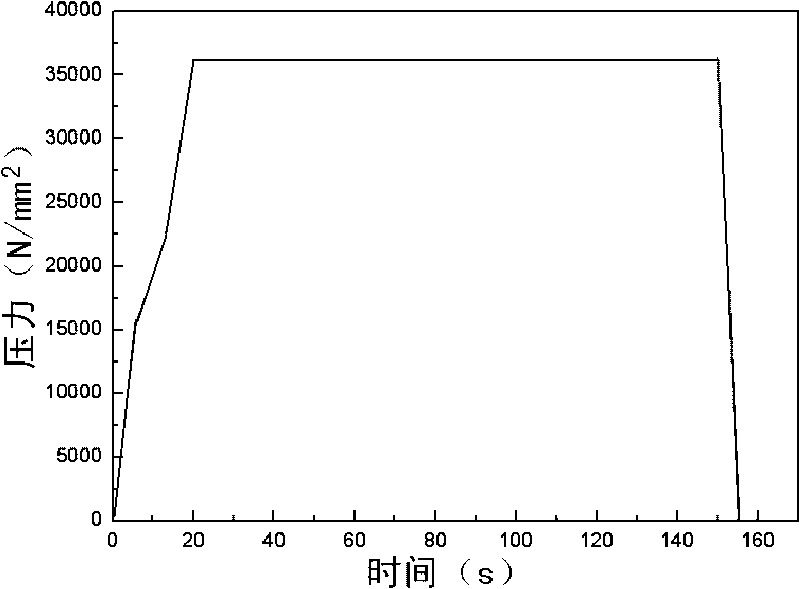

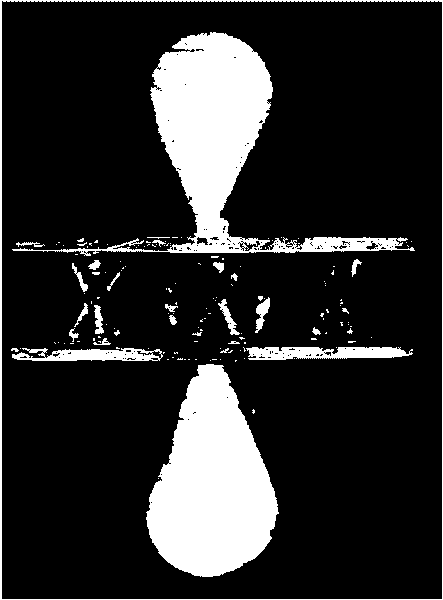

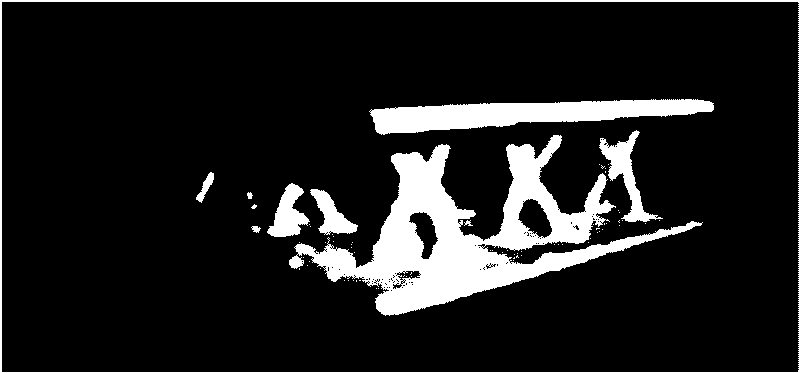

[0010] Embodiment 1: The low-pressure casting method of the lattice sandwich panel in this embodiment is realized through the following steps: 1. The wax mold of the lattice sandwich panel is prepared by using fused deposition rapid prototyping equipment; 2. On the surface layer of the wax mold Apply ceramic slurry evenly, then dry at 18-22°C for 20-24 hours, then evenly sprinkle a layer of zirconia sand, then apply ceramic slurry evenly on the adjacent surface layer of the wax model, and then dry at 18-22°C After 20 to 24 hours, sprinkle a layer of zirconia sand evenly. The ceramic slurry applied on the surface layer is obtained by uniformly mixing zirconia and silica sol in a mass ratio of 4.5:1. The ceramic slurry applied on the adjacent surface layer It is obtained by uniformly mixing zirconium dioxide and silica sol at a mass ratio of 4.0:1; 3. Apply ceramic slurry evenly on the back layer of the wax model, then dry at 18-22°C for 3-8 hours, and then evenly spread A layer...

specific Embodiment approach 2

[0013] Embodiment 2: This embodiment differs from Embodiment 1 in that the model of the fused deposition rapid prototyping equipment in step 1 is FDM3000. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0014] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 2, evenly apply ceramic slurry on the surface layer of the wax model, and then evenly sprinkle a layer of zirconia sand after drying at 20°C for 22 hours. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com