Compound disinfectant for livestock and poultry raising environment

A technology for livestock and poultry breeding and disinfectants, which is applied in the direction of disinfectants, chemicals for biological control, applications, etc., can solve problems such as difficult-to-clean stains, pathogenic microorganism contamination, contamination, etc., to reduce usage and reduce Stimulating, production cost-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The content of each component of compound disinfectant is by weight percentage:

[0017] 0.0625% o-phthalaldehyde, 0.0005% decyl ammonium bromide, 2.5% cosolvent, 0.1% metal chelating agent, 0.1% stable corrosion inhibitor, and the balance is water.

[0018] The sum of each component in the above scheme is 100%.

[0019] Preparation process: Weigh 0.625g of o-phthalaldehyde, dissolve it in 25g of absolute alcohol, add a small amount of water, then add 0.0072g of decyl ammonium bromide (70% by weight), 1g of ethylenediaminetetraacetic acid, 1g of Fatty alcohol polyoxyethylene ether, mix well, add water to make up to volume, make 1000g compound disinfectant, set aside.

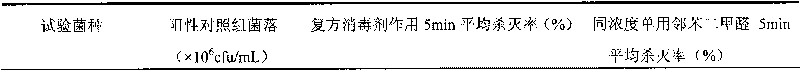

[0020] (1) Suspension Quantitative Bactericidal Test

[0021] (1) Dilute the bacterial suspension to 10 with sterile saline 8 cfu / mL; (2) According to the measurement results, prepare a compound disinfectant solution of o-phthalaldehyde and decylammonium bromide at an appropriate concentration, and put...

Embodiment 2

[0062] Each component content by weight percentage in the compound disinfectant is:

[0063] 1% o-phthalaldehyde, 0.0001% decyl ammonium bromide, 5% co-solvent, 0.1% metal chelating agent, 0.001% stable corrosion inhibitor, and the balance is water.

[0064] The sum of each component in the above scheme is 100%.

[0065] Preparation process: Weigh 10g of phthalaldehyde, dissolve it in 50g of absolute alcohol, add a certain amount of water and stir until the phthalaldehyde is dissolved, then add 0.0014g of decyl ammonium bromide (70% by weight), 1g Ethylenediaminetetraacetic acid, 0.01g fatty alcohol polyoxyethylene ether, after mixing evenly, add water to make up to volume, make 1000g compound disinfectant, set aside.

[0066] (1) The results of the suspension quantitative bactericidal test are as follows:

[0067]

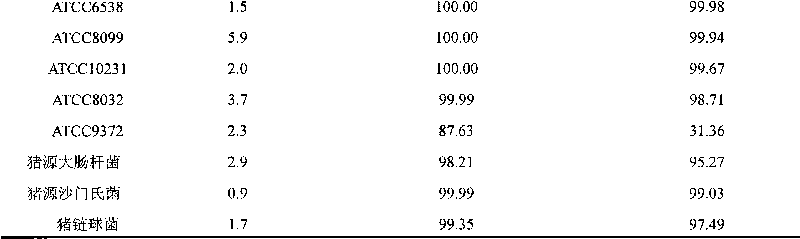

[0068] (2) The results of the ground dirt disinfection test:

[0069] The sterilizing rate of the compound o-phthalaldehyde disinfectant after 30 minutes of...

Embodiment 3

[0078] The content of each component of compound o-phthalaldehyde disinfectant is calculated by weight percentage:

[0079] 0.05% o-phthalaldehyde, 0.05% decyl ammonium bromide, 1% cosolvent, 1% metal chelating agent, 1% stable corrosion inhibitor, and the balance is water.

[0080] The sum of each component in the above scheme is 100%.

[0081] Preparation process: Weigh 0.5g of phthalaldehyde, dissolve it in 10g of absolute alcohol, add a certain amount of water and stir until the phthalaldehyde is dissolved, then add 0.72g of decylmethylammonium bromide (70% by weight), 10g Ethylenediamine tetraacetic acid, 10g fatty alcohol polyoxyethylene ether, after mixing evenly, add water to make up to volume, make 1000g compound disinfectant, set aside.

[0082] (1) The results of the suspension quantitative bactericidal test are as follows:

[0083]

[0084] (2) The results of the ground dirt disinfection test:

[0085] The bactericidal rate of the compound o-phthalaldehyde di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com