High-adhesion benzene-free environmentally-friendly universal jet ink and preparation method thereof

A high-adhesion, code-jetting technology, applied in the direction of ink, applications, household appliances, etc., can solve the problems of low surface adhesion and unsatisfactory adhesion performance of polyethylene materials, and achieve excellent adhesion performance, reduced hazards, and rapid drying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

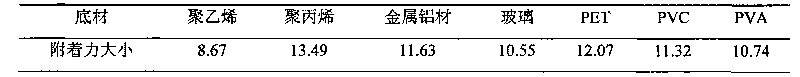

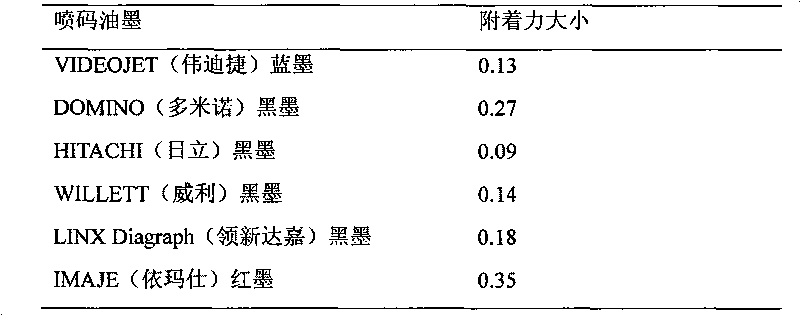

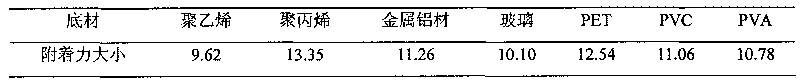

Examples

Embodiment 1

[0034] A raw material formula of inkjet printing ink is as follows:

[0035] CPP814HS (Nippon Paper Chemicals Co., Ltd. Superchlon series) 5 parts

[0036] Acrylic resin FS-2820 (Shanghai Deqian Chemical Co., Ltd.) 1 part

[0037] Butanone 89 parts

[0038] Solvent Black 34 2 parts

[0039] 0.5 parts of dimethylamine hydrochloride

[0040] 1 part diethyl phthalate

[0041] 0.5 parts of liquid paraffin

[0042] EFKA 5065 (Dutch Ciba-Efka Company) 0.5 parts

[0043] AFCONA 2048 (Asia Afcona Company) 0.5 parts

[0044] Preparation process:

[0045] According to the above raw material ratio, weigh 5 parts by weight of modified chlorinated polypropylene resin CPP814HS and 1 part of acrylic resin FS-2820, put them into 59 parts of butanone, stir at room temperature until the resin is completely dissolved, and obtain solution A. At the same time, dissolve 2 parts of solvent black 34, 0.5 parts of dimethylamine hydrochloride, 1 part of diethyl phthalate, 0.5 parts of liquid pa...

Embodiment 2

[0054] A raw material formula of inkjet printing ink is as follows:

[0055] CPP814HS (Nippon Paper Chemicals Co., Ltd. Superchlon series) 6 parts

[0056] Acrylic resin B-66 (Rohm and Haas, USA) 3 parts

[0057] Butanone 84 parts

[0058] Solvent Black 34 4 parts

[0059] 0.5 parts of dimethylamine hydrochloride

[0060] 1 part diethyl phthalate

[0061] 0.5 parts of liquid paraffin

[0062] EFKA 5065 (Dutch Ciba-Efka Company) 0.5 parts

[0063] AFCONA 2048 (Zhou Afcona Company) 0.5 parts

[0064] Preparation process:

[0065] According to the above raw material ratio, weigh 6 parts of modified chlorinated polypropylene resin CPP814HS and 3 parts of acrylic resin B-66, put them into 54 parts of butanone, stir at room temperature until the resin is completely dissolved, and obtain solution A. At the same time, dissolve 4 parts of Solvent Black 34, 0.5 parts of dimethylamine hydrochloride, 1 part of diethyl phthalate, 0.5 parts of liquid paraffin, 0.5 parts of EFKA 5065...

Embodiment 3

[0071] A raw material formula of inkjet printing ink is as follows:

[0072] CPP883S (Guangzhou Tianyi Trading Co., Ltd.) 8 copies

[0073] Acrylic resin MB-2952 (Rohm and Haas, USA) 2 copies

[0074] Butanone 80 parts

[0075] Solvent Black 27 5 parts

[0076] Dimethylamine hydrochloride 1 part

[0077] Dibutyl phthalate 1.5 parts

[0078] 0.5 parts of liquid paraffin

[0079] EFKA 8385 (Dutch Ciba-Efka Company) 1 part

[0080] AFCONA 5065 (Zhou Afcona Company) 1 part

[0081] Preparation process:

[0082] According to the above raw material ratio, weigh 8 parts of modified chlorinated polypropylene resin CPP883S and 2 parts of acrylic resin MB-2952, put them into 50 parts of butanone, and stir at room temperature until the resin is completely dissolved. At the same time, dissolve 5 parts of solvent black 27, 1 part of dimethylamine hydrochloride, 1.5 parts of dibutyl phthalate, 0.5 parts of liquid paraffin, 1 part of EFKA 8385 and 1 part of AFCONA5065 with 30 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com