Hydrogenation catalyst composition and application thereof in hydrogenated conjugated diene polymer

A technology of composition and titanium compound, applied in the direction of organic compound/hydride/coordination complex catalyst, chemical/physical process, physical/chemical process catalyst, etc., can solve the problem of inability to obtain good hydrogenation degree of polymer, reaction operating pressure high cost, high equipment cost, etc., to achieve the effect of good activity persistence, low residue and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

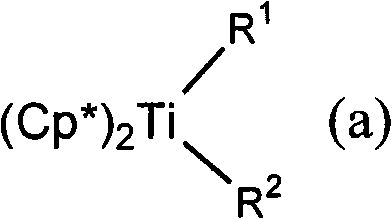

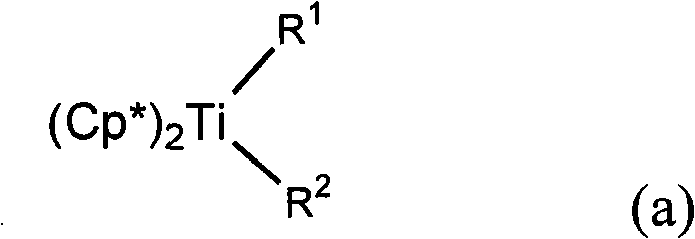

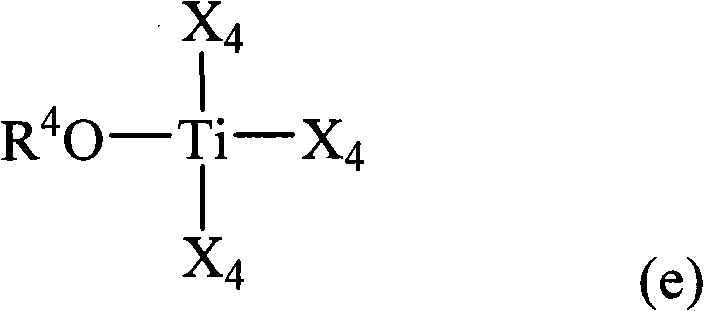

Method used

Image

Examples

Embodiment 1

[0099] After the above-mentioned preparation examples obtained the conjugated diene polymer glue, feed hydrogen (5kg / cm 2 ) to the reactor nitrogen N 2 Get rid of, and prepare the solution of each component of hydrogenation catalyst composition, dicyclopentadienyl titanium dichloride (Cp 2 TiCl 2 ) is dissolved in cyclohexane to form a 0.12% by weight solution, polymethylhydrogensiloxane is dissolved in cyclohexane to form a 0.75% by weight solution, tetrakis(isopropoxy)titanium (TPT) is dissolved in cyclohexane to form 0.2% by weight solution and n-butyllithium were dissolved in cyclohexane to form an 8% by weight solution; the prepared hydrogenation catalyst composition was added to the reactor according to the amounts in Table 1, and the hydrogenation temperature was 75 ° C. Pressure 5kg / cm 2 hydrogenation under the conditions of 8 hours to obtain the hydrogenated conjugated diene polymer of the present invention; The operating pressure and hydrogenation temperature of ...

Embodiment 2~11

[0101] The same operation mode as in Example 1, and according to the formula and hydrogenation conditions of the hydrogenation catalyst composition in Table 1, the hydrogenated conjugated diene polymer of the present invention, the degree of hydrogenation and the trans The structural residues are shown in Table 3. In addition, the hydrogenated conjugated diene polymers in Examples 2-11 have no odor, and the hydrogenated conjugated diene polymers in Examples 2-3 are yellow in appearance after thermal stability testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com