Dual testing room measured material outgassing rate measuring device and method

A test chamber and double test technology, applied in the preparation of test samples, analytical materials, instruments, etc., can solve problems such as inability to eliminate influence and complex structure, and achieve the effect of improving vacuum degree, facilitating baking, and eliminating influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing of description, the present invention is described in detail:

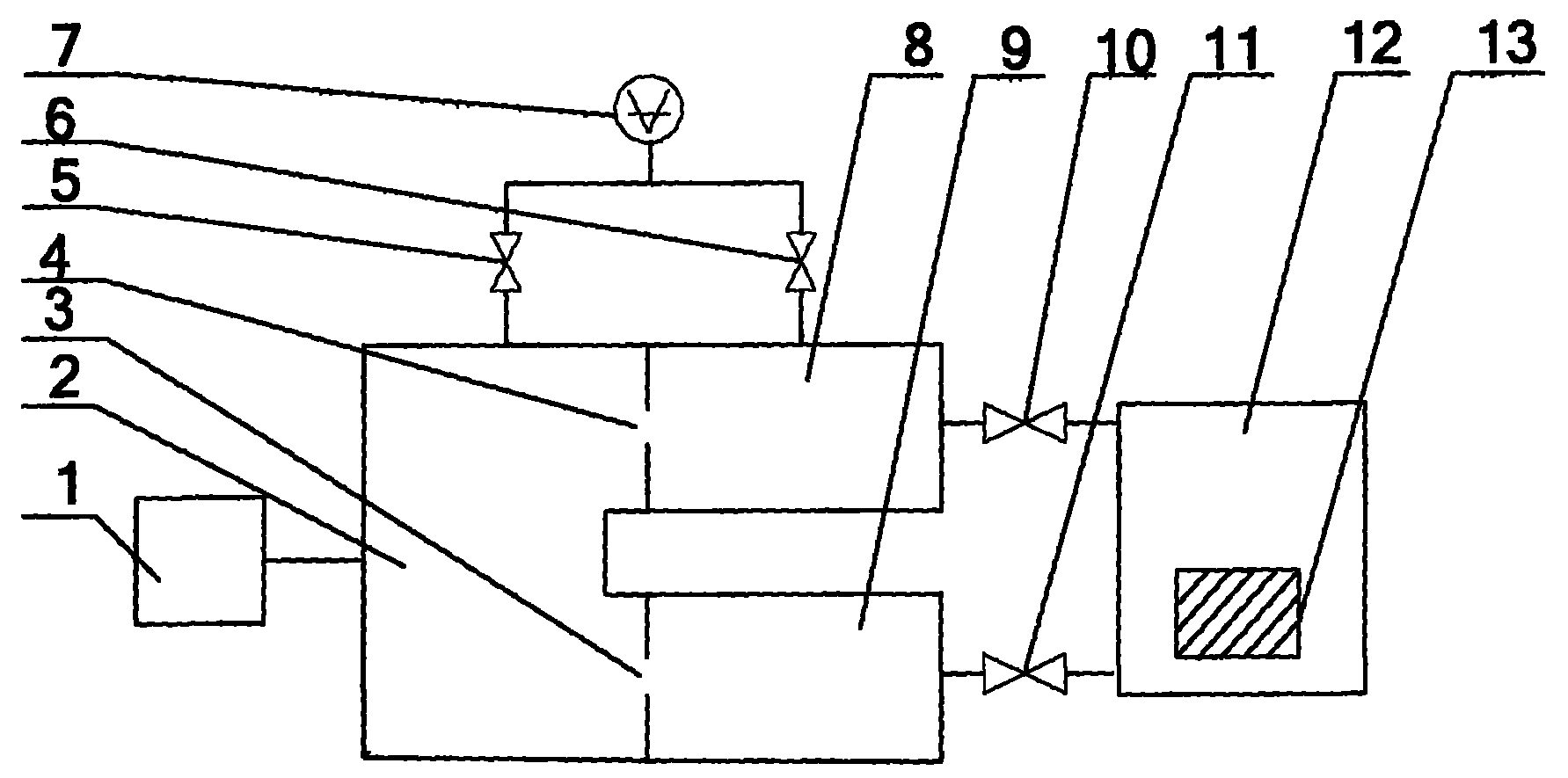

[0044] The device of double testing room of the present invention to measure material outgassing rate is as figure 1 As shown, it includes a high vacuum chamber 12, a symmetrical test chamber A8 and a test chamber B9, an ultra-high vacuum chamber 2, a separation gauge 7, ultra-high vacuum angle valves 5, 6, two straight-through valves 10 and 11, and a bimolecular pump Gas system 1, the interface is all sealed with metal, which is resistant to high temperature baking. The bimolecular pump pumping system 1 is directly connected to the ultra-high vacuum chamber 2; the ultra-high vacuum chamber 2 communicates with two symmetrical test chambers A8 and B9 respectively through small holes, and the diameter of the small holes is 8.1mm. The design can make the flow conductance of the small hole 6L / s; the separation gauge 7 is bridged on the ultra-high vacuum chamber 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com