Super electrolytic capacitor paper

An electrolytic capacitor paper and super technology, applied in circuits, electrical components, organic insulators, etc., can solve the problems of large leakage current and poor energy storage performance of capacitors, and achieve the effects of small leakage current, low loss and small aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

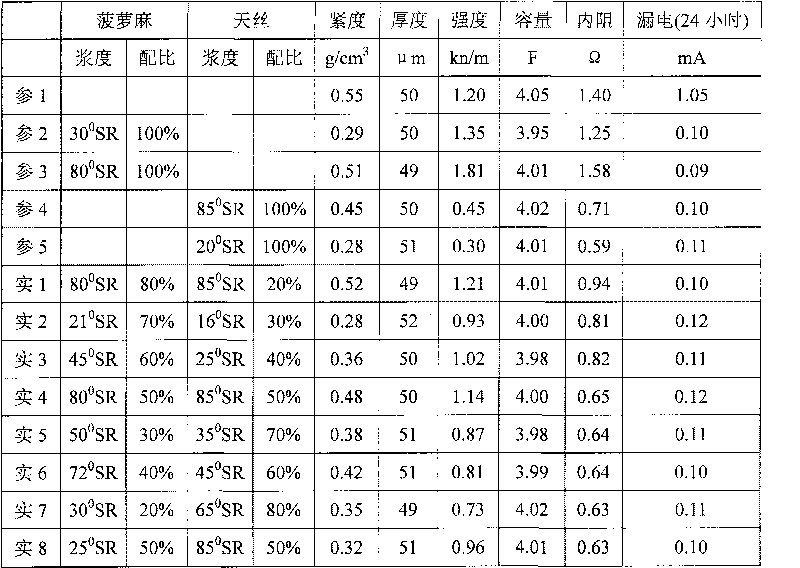

Examples

example 2

[0018] Pineapple hemp pulp is beaten at 30°SR, paper is made by fourdrinier paper machine, the paper making process is as conventional, and the conventional indicators such as paper sheet detection quantity and strength are made into the leakage current, internal resistance, capacity and other indicators of supercapacitor test capacitors.

[0019] Reference example 3

[0020] The pineapple hemp pulp is beaten at 80°SR, and the paper is made by a rotary paper machine. The papermaking process is as conventional as the conventional process, and the conventional indicators such as the quantitative and strength of the paper are tested, and the leakage current, internal resistance, capacity and other indicators of the supercapacitor test capacitor are made.

example 4

[0022] Tencel pulp is beaten at 85°SR, and the cylinder paper machine is used for papermaking. The papermaking process is such as the conventional process, and the conventional indicators such as the quantitative and strength of the paper sheet are tested, and the leakage current, internal resistance, capacity and other indicators of the supercapacitor test capacitor are made.

example 5

[0024] Tencel fiber is beaten at 20°SR, and the paper is made by a side wave net paper machine. The papermaking process is like a conventional process, and the conventional indicators such as the quantitative and strength of the paper sheet are tested, and the leakage current, internal resistance, capacity and other indicators of the supercapacitor test capacitor are made.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com