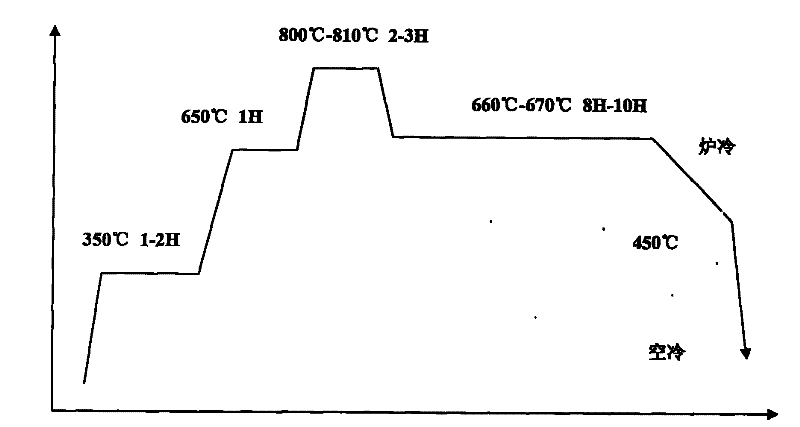

Three-stage temperature annealing process for 30CrMnSiA cold rolled steel part

An annealing process and cold-rolled steel technology, which is applied in the field of heat treatment, can solve problems affecting the surface quality of stamping parts, cracking of cold-rolled steel plates, scrapping of stamping parts, etc., and achieve the effects of improving deformation, stamping forming, and increasing ductility and plasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Part name: large box base, material: 30CrMnSiA, raw material state: cold-rolled steel plate. After three stamping processes, the parts are formed into the final part shape from the raw material cold-rolled steel plate. The technical requirements are: the bottom plane of the part is ≤0.30mm, and the flatness of the upper surface is ≤0.30mm. The inner cavity height is 27.2mm, the upper deviation is 0.28mm, and the lower deviation is 0mm. The inner cavity width is 95.5mm, the upper deviation is 0.87mm, the lower deviation is 0mm, the part length is 630mm, and the part thickness is 6mm.

[0015] Firstly, the raw material steel plate (raw material length 630mm, width 204mm, thickness 6mm) that has been cut and cut is put into a container, and the container is put into a low-vacuum well-type gas-protected resistance furnace, and the well-type resistance furnace starts to evacuate to 0.1Mpa, stop vacuuming, pass in nitrogen (purity above 99.95%), the electric furnace starts h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com