Filling station of semi-submersible type drilling platform

A technology for drilling platforms and filling stations, applied in the field of filling stations, can solve problems such as troublesome operation, easy damage to hoses, and reduced service life, and achieve the effects of simple and convenient operation, reduced labor intensity, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

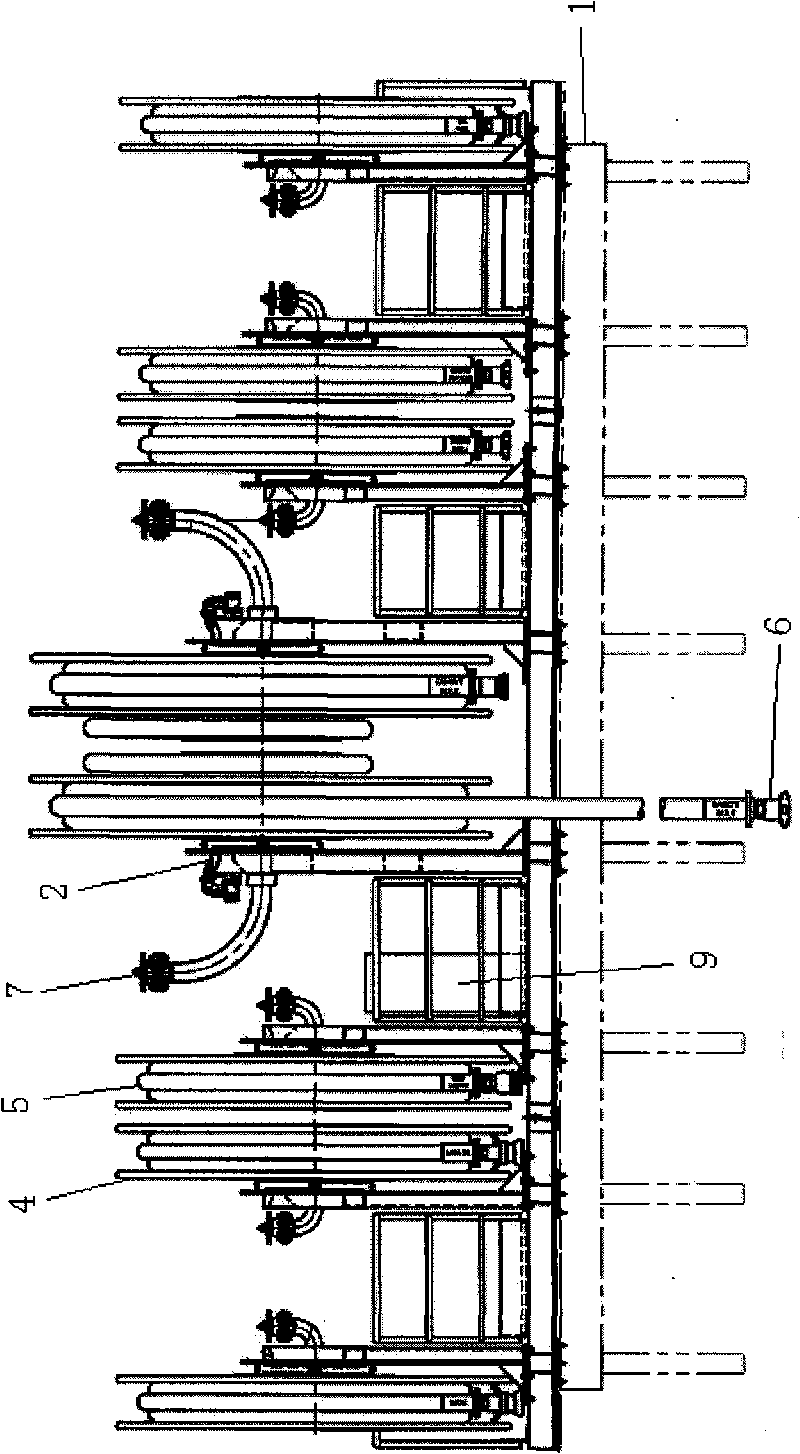

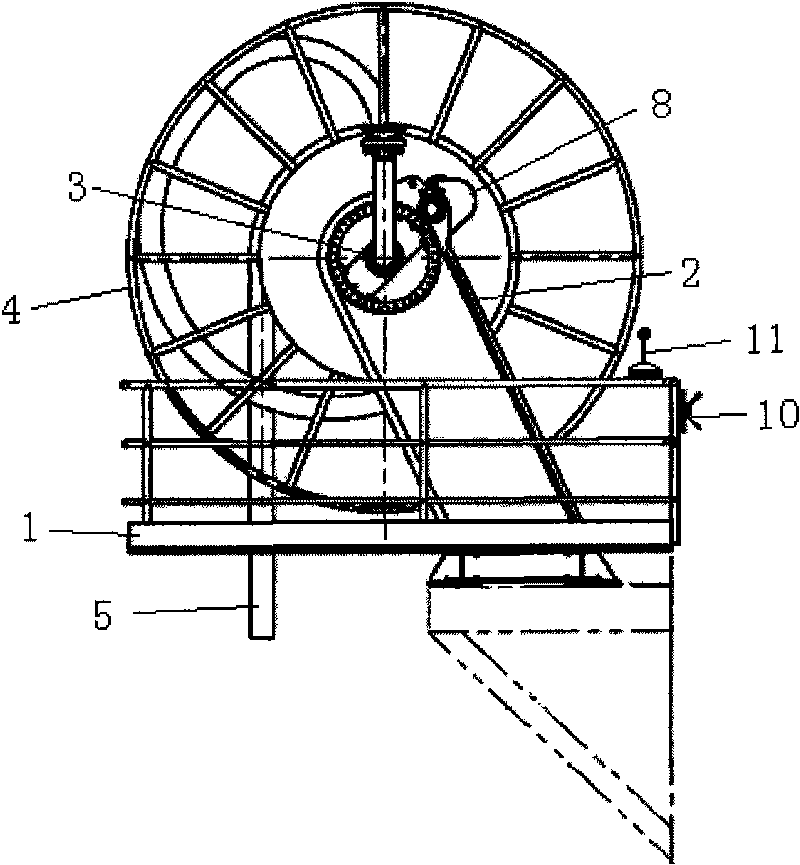

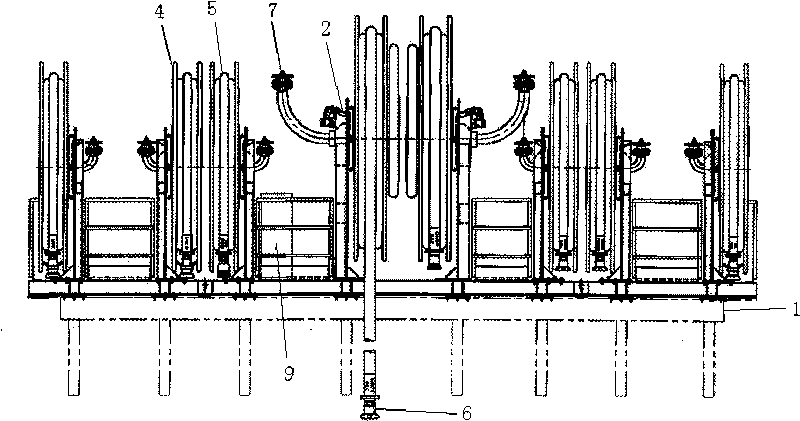

[0009] Such as figure 1 , figure 2 As shown, the present invention includes a base 1 fixed on the starboard and starboard sides of the main deck of the platform. There are several groups of horizontally arranged brackets 2 on the base 1, and each group of brackets 2 is supported by a horizontally arranged rotating shaft 3 with 1~ 2 drums 4, each drum 4 is wound with a hose 5, used to add a consumable or operating material, such as fuel oil, fresh water, drilling water, water-based mud, oil-based mud, salt water, soil powder and cement etc. One end of each flexible pipe 5 is provided with a quick joint 6 connected to the supply ship, and the other end is connected with a hard pipe joint 7 fixed on the outside of the support 2, and the hard pipe joint 7 is used to connect the corresponding storage station on the platform. The rotating shaft 3 of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com