Forming machine for screw thread

A forming machine and threading technology, which is applied to other household appliances, household appliances, applications, etc., can solve the problems of use restrictions, restricting large-scale processing and production of threading, and achieve the effects of improved mechanization, compact structure, and convenient processing and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

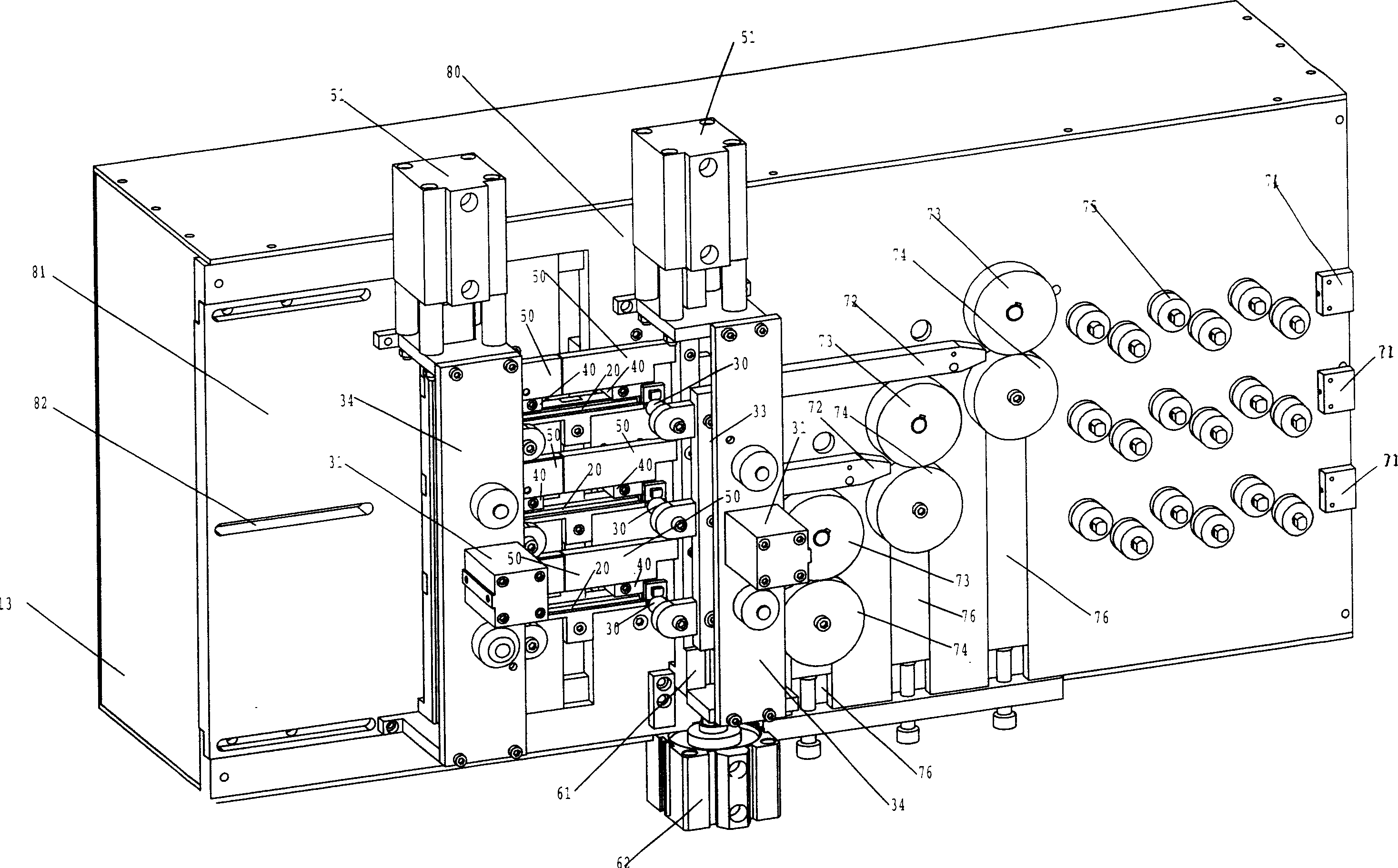

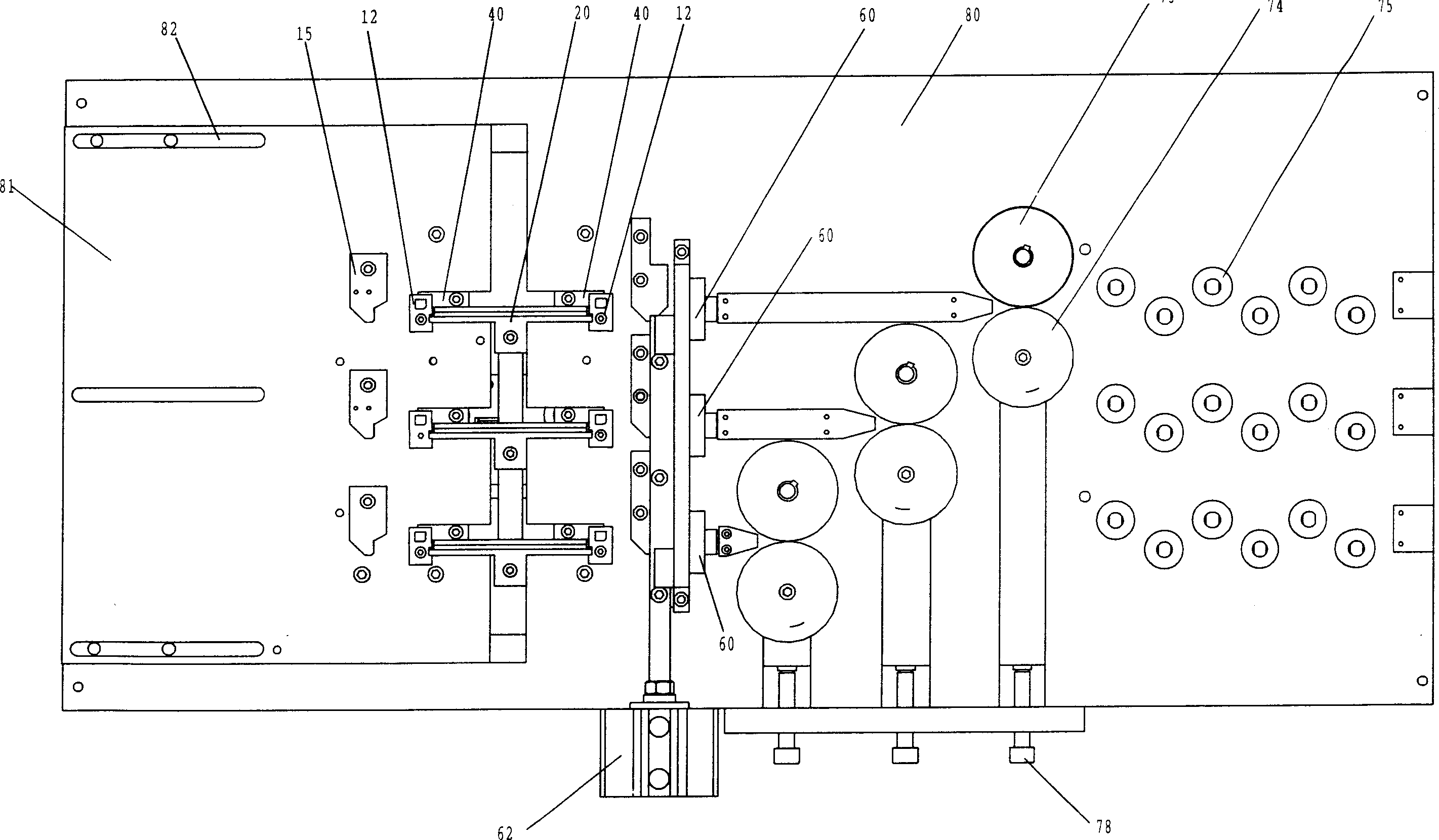

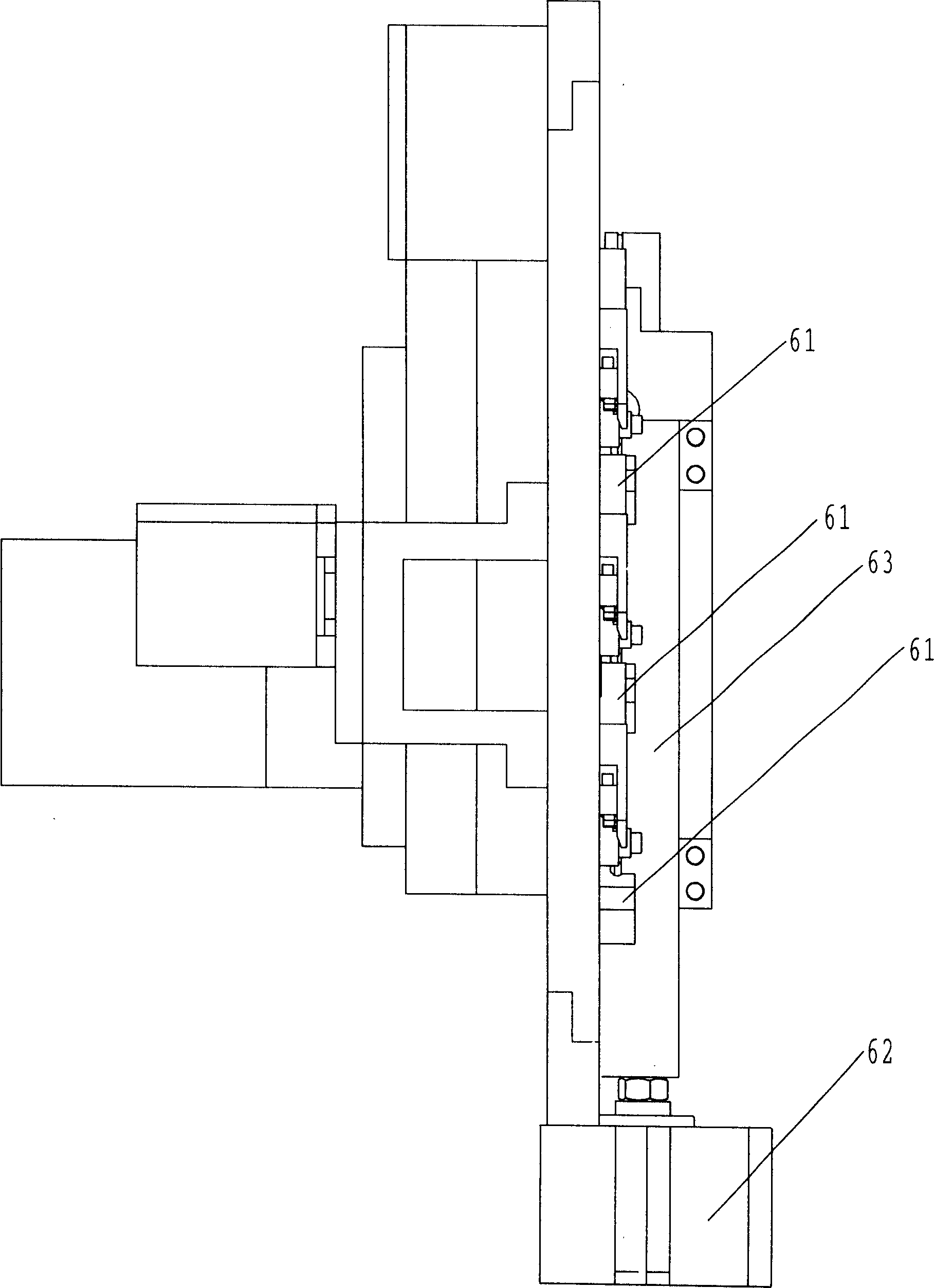

[0044] refer to figure 1 , 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13. The most basic structural form of the present invention can be made of a set of wire bending head, rotary drive, wire guide, fastening, preliminary forming, final forming and wire cutting mechanism. At this time, the symmetrically arranged wire bending heads 12 and the rotating drive mechanism are arranged along the plate surface of the plate frame 13 . The wire guide plate telescopic cylinder 21 in the wire guide mechanism is horizontally arranged on the back side of the plate frame 13, and its piston rod is connected with the wire guide plate 20 between the symmetrical wire bending heads 12. The pressure head telescopic cylinder 31 in the clamping mechanism is horizontally placed on figure 1 , 2 The front of middle plate type frame 13, the piston rod 35 ( Figure 13 Middle) is connected with the pressure head 30. Two primary forming push pedals 40 in the primary forming mechanism are symmetrically pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com