Self-propelled Chinese cabbage harvester having variety adaptability and method thereof

A Chinese cabbage, adaptable technology, used in harvesters, applications, agricultural machinery and implements, etc., can solve the problems of high labor intensity and low efficiency, and achieve the effect of reducing the breakage rate, preventing misalignment, and enhancing the versatility of the machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

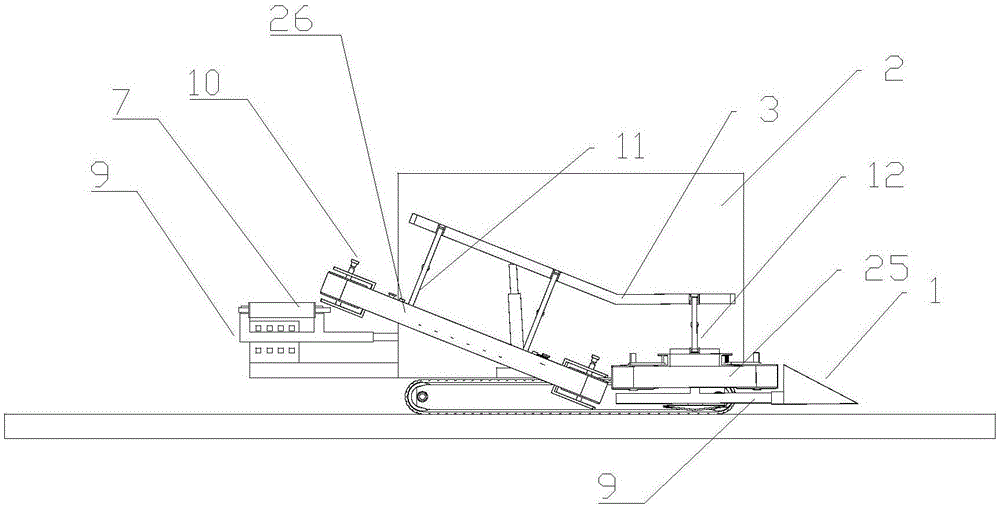

[0039] Below in conjunction with accompanying drawing, the patent of the present invention is further described. Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, and 10: This machine includes: load-bearing beam 3, guiding device 1, hydraulic device, 6 clamping device 25, cutting device, inclined conveying device 26, horizontal conveying device7.

[0040] The load-bearing beam 3 is a load-bearing frame for supporting and fixing other devices; the clamping device 25 is used for clamping and fixing the Chinese cabbage to prevent its position from shifting; the cutting device is used for cutting The root of Chinese cabbage; the guide device 1 is used to guide the whole machine and gather the leafy vegetables; the inclined conveying device 28 is used to transport the Chinese cabbage that cuts off the root; the described horizontal conveying device 7 is used for harvesting The Chinese cabbage is transported into the basket.

[0041] The load-bearing beam 3 is divided into an inclined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com